Detent and pressure plate adjust, Pressure plate adjustment, Edetent and pressure plate adjust – Great Plains 3S-4010HDF Operator Manual User Manual

Page 76

72

3S-4010HD and 3S-4010HDF

Great Plains Manufacturing, Inc.

196-522M

03/28/2012

E

Detent and Pressure Plate Adjust

Refer to Figure 85

The rear casters each have two independent adjust-

ments, which may need some attention as their internal

working surfaces wear over several seasons:

If the casters do not detent during straight-ahead move-

ment, first check the bolt

caster detent pin and/or detent plate as needed.

If the caster is oscillating during transport turns, adjust

the pressure plate bolt

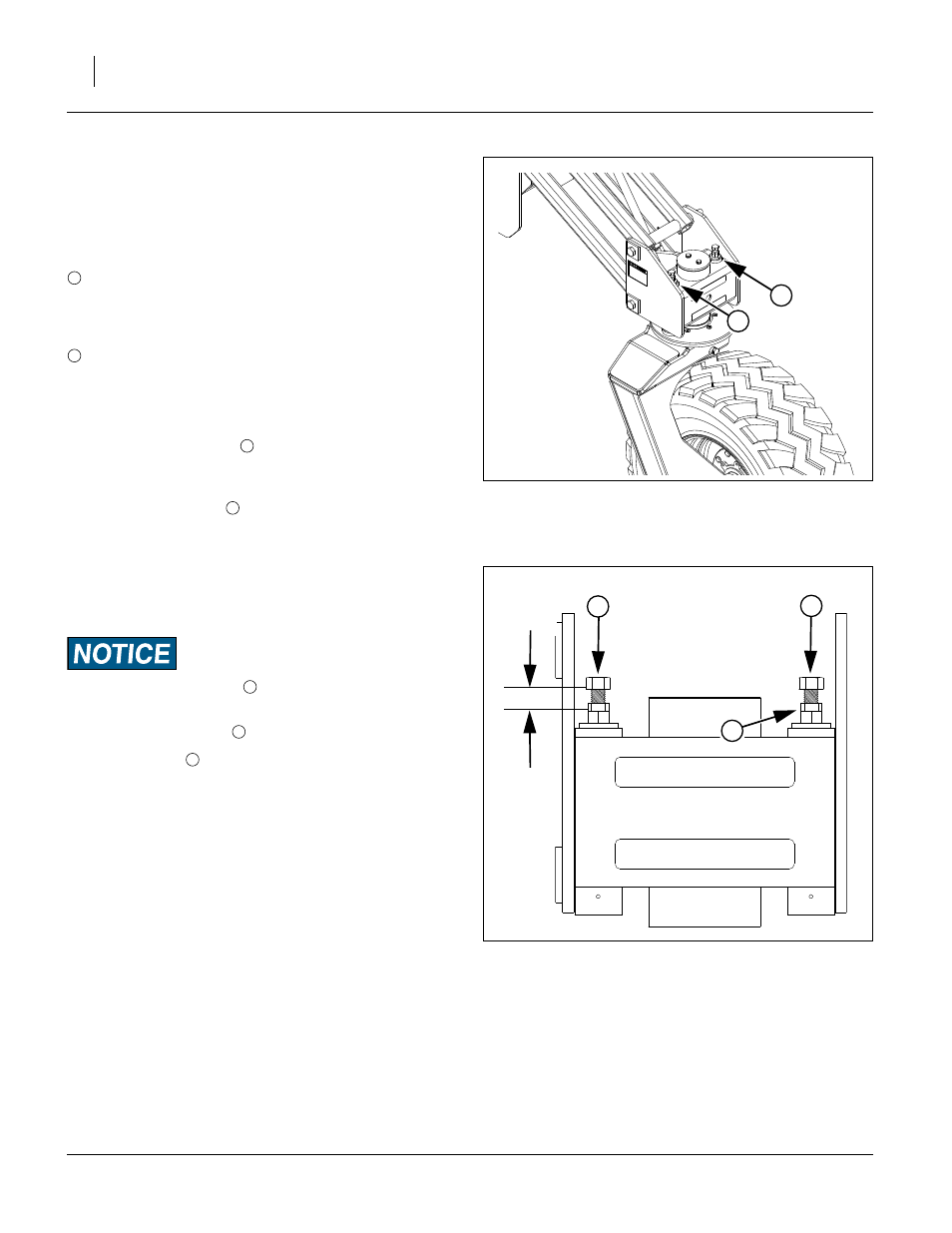

Refer to Figure 86

The factory setting for both adjustments is 1in (2.5cm)

from the face of the bolt head to the top of the weldment.

If pressure plate or detent components are ever

replaced, return the bolts to the factory setting.

Never adjust the detent bolt

to less than 1in.

Pressure Plate Adjustment

1.

Loosen the jam nut

2.

Turn the bolt

clockwise until the spring is fully

compressed.

3.

Back the bolt out

1

⁄

4

in (6mm).

4.

Tighten the jam nut.

FigureSpacer:

Caster Detent (on the outside, both sides):

This feature snaps the caster into the full trailing

position for straight-ahead movement. It helps keep

the drill running true in the field and in transport.

Caster Pressure Plate (on the inside, both sides):

This feature acts as a pivot brake, and helps prevent

caster oscillation during transport.

FigureSpacer:

Figure 85

Rear Caster Adjustments

(left side shown)

29224

2

1

1

2

FigureSpacer:

Figure 86

Rear Caster Adjustment Bolts

(right side shown)

29223

3

FigureSpacer:

1 in

2.5 cm

3