Front-to-back level – Great Plains 3S-4010HDF Operator Manual User Manual

Page 71

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

67

03/28/2012

196-522M

Front-to-Back Level

Level the drill front-to-rear using only the eyebolts

located on the rear axle. Adjust only until level front-to-

rear when drilling in actual seeding conditions.

Note: Drill must be level front to rear in actual planting use

or row plugging will occur. Adjusting gauge wheel

depth stop too low or excess opener spring force

can cause the front of drill to roll forward when

planting. Conventional till ground can also cause

drill to run low in the front if gauge wheel depth is

set too low.

In representative field conditions, lower the drill and

pull forward to place openers in ground. If openers

a

are operating at desired depth, and row units are

parallel to the ground, check frame level front-to-

back.

Note: When drill is level, opener bodies will be level or

slightly higher at rear.

Adjustment Starting Point:

2.

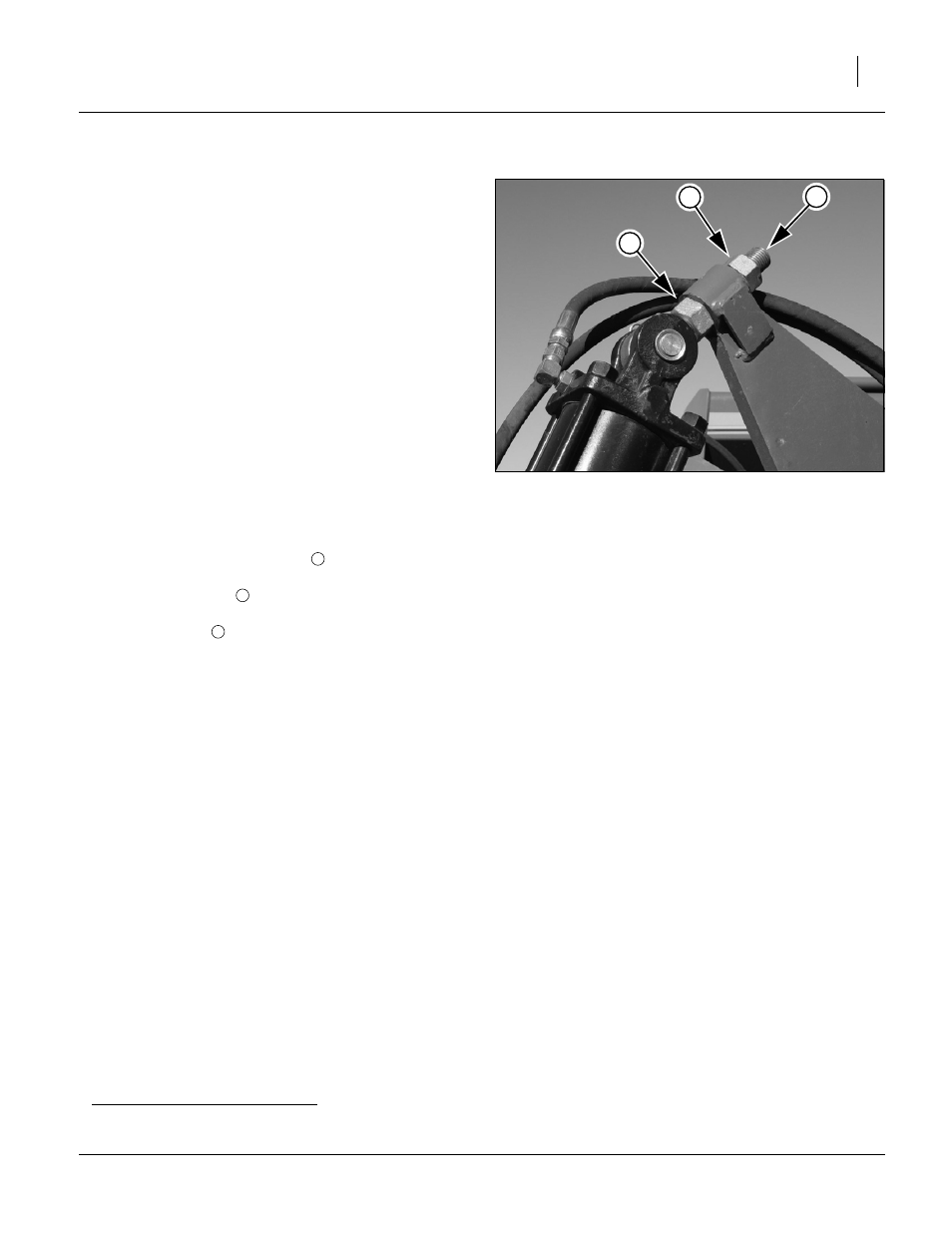

Locate the threaded eyebolts

the rear axle cylinders. The eye bolt is locked in

place by a jam nut

. Observe the amount of thread

exposed above the upper nut and below the lower

adjustment nut

. If the exposed threads are roughly

equal, no initial adjustment is needed. Go to step 4.

3.

If the exposed threads above and below the nuts are

not equal, loosen and adjust the jam nuts until the

amount of exposed thread is about the same above

and below for both eyebolts.

Adjustment Procedure:

4.

Lower the drill into actual seeding conditions.

5.

Have an assistant check front to rear level while

planting by observing the drill from a safe distance.

Drill should run with frame level or slightly lower in

the front. Adjust eyebolts as needed.

a. If openers are not level, or at correct depth, adjust depth and down-force settings before adjusting frame level.

FigureSpacer:

Figure 78

Rear Lift Eyebolt

20316

4

5

6