Tweco 550i Transmig User Manual

Page 52

TRANSMIG 350i, 450i, 550i

BASIC WELDING GUIDE

4-8

Manual 0-5205

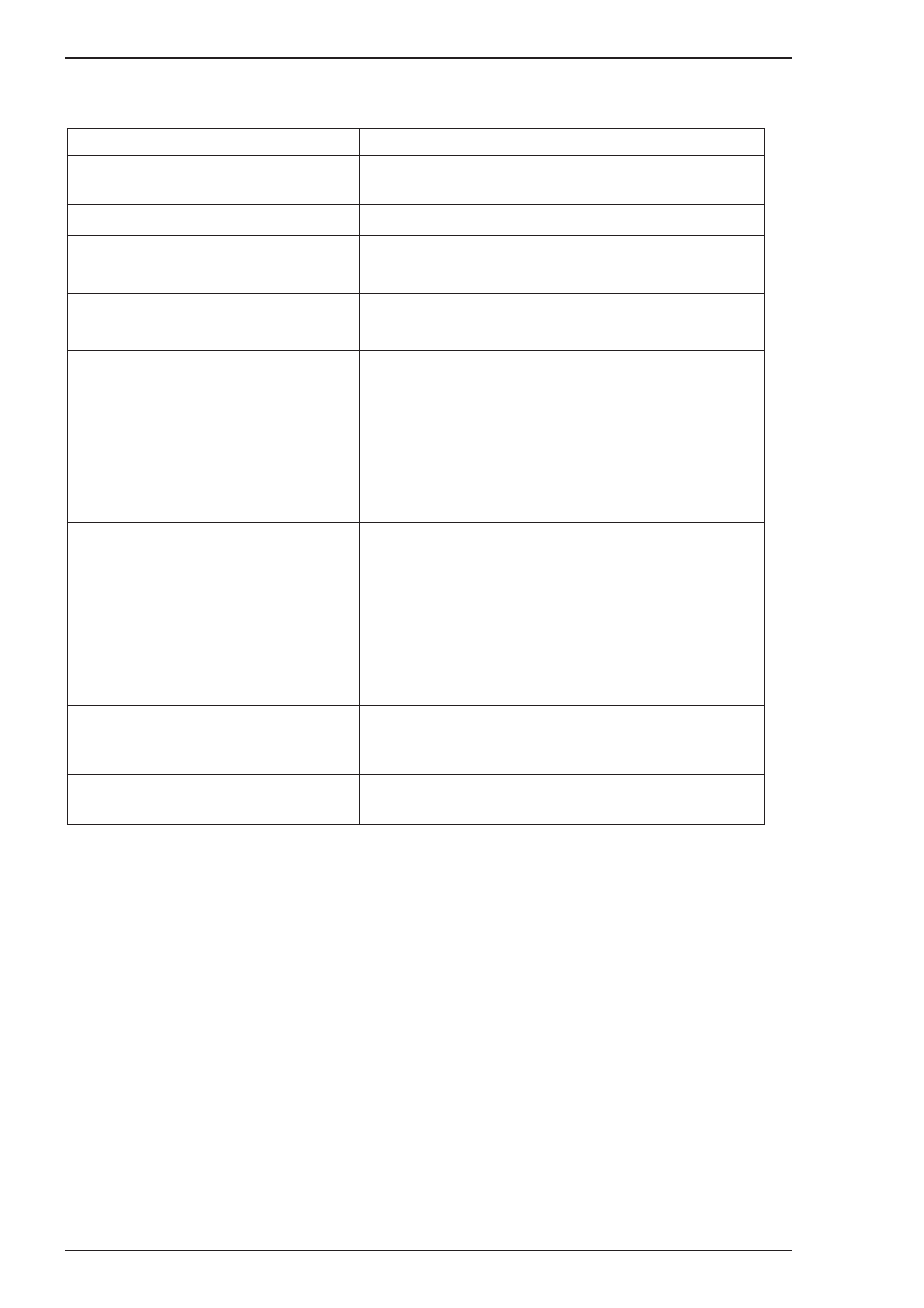

Solving Problems Beyond the Welding Terminals - Inconsistent Wire Feed

Wire feeding problems can be reduced by checking the following points.

FAULT

CAUSE

1 Feed roller driven by motor in the

cabinet slipped.

Wire spool brake is too tight.

2 Wire spool unwinded and tangled.

Wire spool brake is too loose.

3 Worn or incorrect feed roller size

A Use a feed roller matched to the size you are welding.

B Replace feed roller if worn.

4 Wire rubbed against the mis-aligned

guides and reduced wire feedability.

Mis-alignment of inlet/outlet guides

5 Liner blocked with swarf

A Increased amounts of swarf are produced by the wire

passing through the feed roller when excessive pres-

sure is applied to the pressure roller adjuster.

B Swarf can also be produced by the wire passing

through an incorrect feed roller groove shape or size.

C Swarf is fed into the conduit liner where it accumu-

lates thus reducing wire feedability.

6 Incorrect or worn contact tip

A The contact tip transfers the weld current to the elec-

trode wire. If the hole in the contact tip is too large

then arcing may occur inside the contact tip resulting

in the wire jamming in the contact tip

B When using soft wire such as aluminium it may

become jammed in the contact tip due to expansion of

the wire when heated. A contact tip designed for soft

wires should be used.

7 Poor work lead contact to work piece

If the work lead has a poor electrical contact to the

work piece then the connection point will heat up and

result in a reduction of power at the arc.

8 Bent liner

This will cause friction between the wire and the liner

thus reducing wire feedability

Table 4-2: Wire Feeding Problems