Tweco 550i Transmig User Manual

Page 28

TRANSMIG 350i, 450i, 550i

INSTALLATION, OPERATION AND SETUP 3-8 Manual 0-5205

11. Thermal Overload Indicator Light (Fault)

This welding power source is protected by a self resetting thermostat. The indicator will illuminate if the

duty cycle of the power source has been exceeded. Should the thermal overload indicator illuminate the

output of the power source will be disabled. Once the power source cools down this light will go OFF and

the over temperature condition will automatically reset. Note that the mains power switch should remain

in the on position such that the fan continues to operate thus allowing the unit to cool sufficiently. Do not

switch the unit off should a thermal overload condition be present.

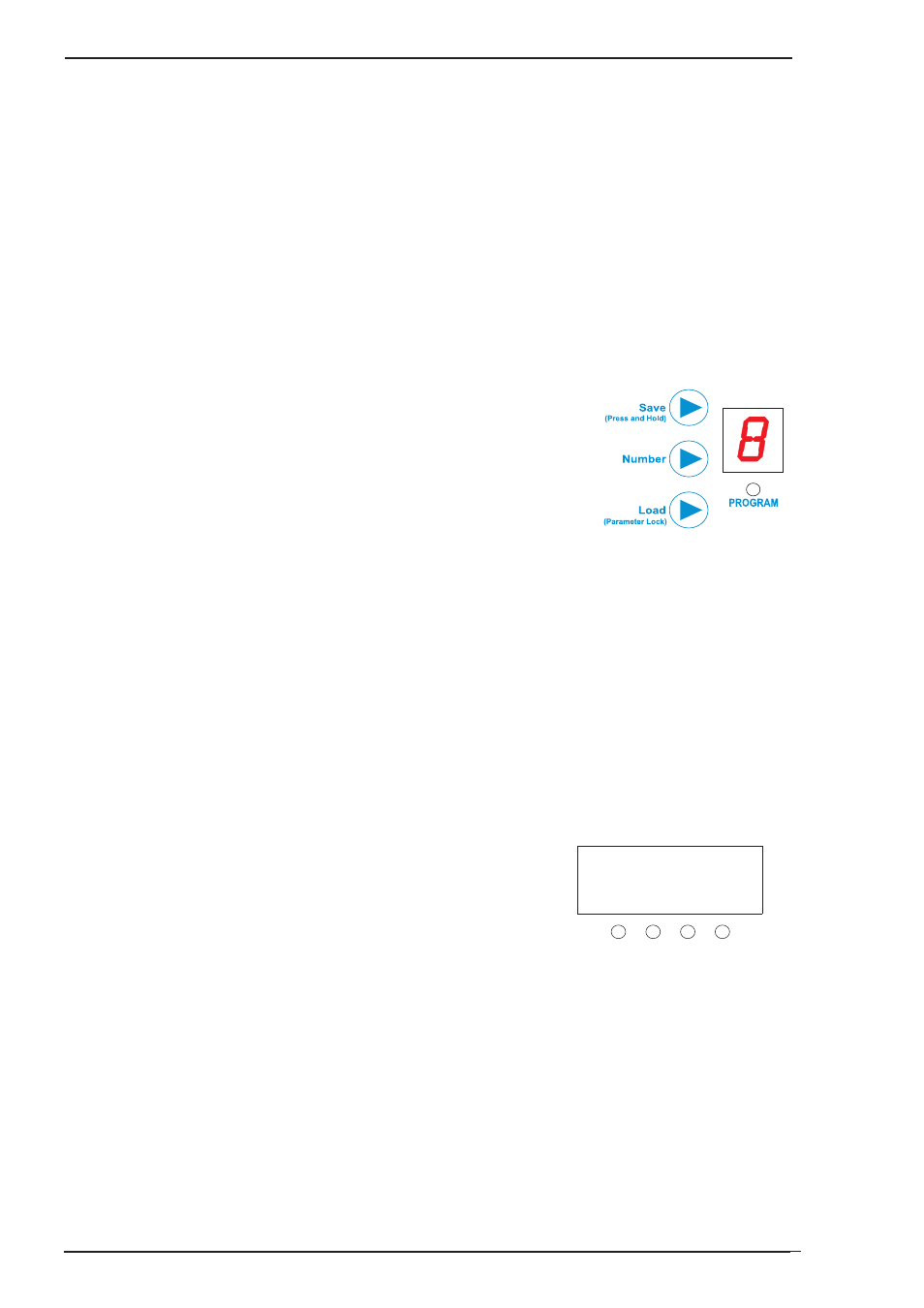

12. Program Storage Buttons and Display

This welding power source is able to store 10 machine setups in memory for MIG (10 pin only), Stick and

Lift Tig modes. This memory is retained even if mains supply power is turned off. Button status, Amps,

Volts, and Wirespeed are stored in memory for quick change between commonly used welding setups.

The memory will store machine setups in all three operating modes, GMAW/FCAW (MIG) (10 Pin only),

GTAW (Lift TIG) and MMAW (Stick).

To STORE a program.

Press the number button. The display will change to indicate

which program number location is being used.

Press and Hold the SAVE button. The number on the display

will flash for 3 seconds.

During this time the current machine setup will be saved in the

numbered program location as selected.

To LOAD a program.

Press the NUMBER button. The display will change to indicate which program is being used.

Press the LOAD button. The PROGRAM light will illuminate.

During this time the machine setup will be loaded into the numbered program location and locked in. To

unlock this press the load button again and the program light will go off.

At any time after a SAVE or LOAD has been performed, manual adjustment of Volts, Amps, Wirespeed or

any button press will return the unit to manual operating mode.

13. Digital Ammeter / Wirefeed Speed / Spot time meter

The digital amperage meter is used to display both the pre-set current (Stick and TIG modes only) and actual

output current (all modes) of the power source. It is also used to display Wirefeed speed and SPOT time.

At times of non-welding, the amperage meter will display a pre-set

(preview) value in both MMAW (Stick) and GTAW (LIFT TIG) modes.

This value can be adjusted by varying the amperage control (item 8)

and the AMPS light will illuminate to indicate AMPS are being displayed.

In 10 PIN GMAW/FCAW (MIG) mode, the amperage meter will preview

wirefeed speed. The IPM (inches per minute) or MPM (metres per minute)

light will illuminate to indicate which wirespeed scale is being used.

In 19 PIN GMAW/FCAW (MIG) mode, the amperage meter will read zero.

When welding, the amperage meter will display actual welding current in all modes.

At the completion of welding, the amperage meter will hold the last recorded amperage value for a period

of approximately 10 seconds in all modes. The amperage meter will hold the value until; (1) any of the

front panel controls are adjusted in which case the unit will revert to preview mode, (2) welding is recom-

menced, in which case actual welding amperage will be displayed, or (3) a period of 10 seconds elapses

following the completion of welding in which case the unit will return to preview mode.

IPM MPM AMPS SEC

A-10631_AB

5 5 0

A-10630