11 options and accessories – Tweco 550i Transmig User Manual

Page 19

TRANSMIG 350i, 450i, 550i

Manual 0-5205 2-7

INTRODUCTION

NOTE

Due to variations that can occur in manufactured products, claimed performance, voltages, ratings,

all capacities, measurements, dimensions and weights quoted are approximate only. Achievable

capacities and ratings in use and operation will depend upon correct installation, use, applications,

maintenance and service. In the interest of continuous improvement, CIGWELD Pty, Ltd reserves

the right to change the specifications or design of any of its products without prior notice.

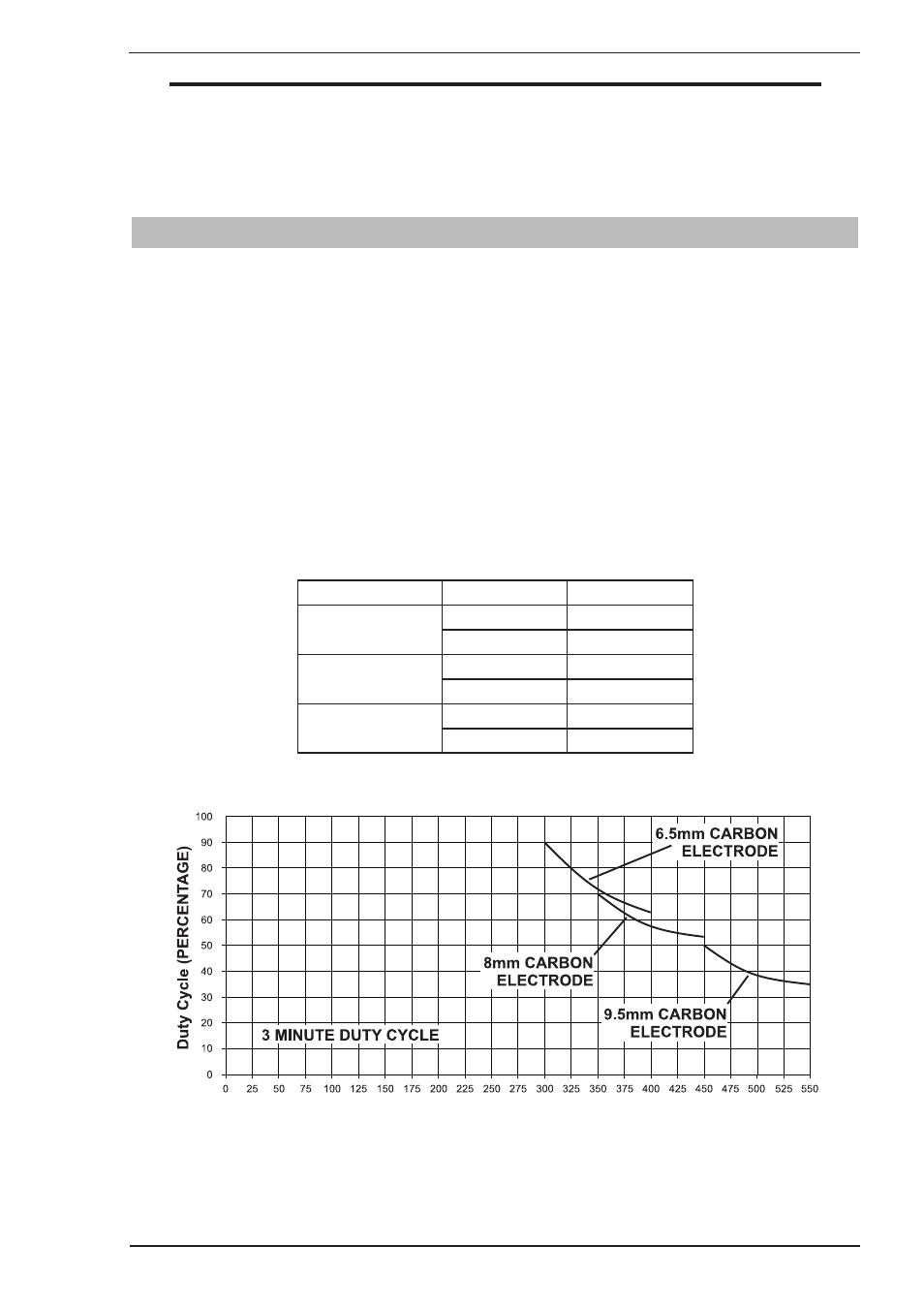

2.11 Gouging Specifications (Transmig 550i only)

Gouging is a process where a copper coated carbon electrode is used to rapidly remove material from the

workpiece.

The arc voltage is much higher during Gouging, than in Stick, or Mig welding. This means, that for the same

output current, we have much higher arc volts during Gouging, and therefore much higher output power. It

is because of this extra output power, that we need to rate the power source differently for gouging, than we

do for welding.

Also as we are drawing a much higher output power from the power source during Gouging, in order to keep

the power source's internal temperatures within acceptable limits, the Duty Cycle for Gouging is specified

over a 3 minute duty cycle period, instead of the normal 10 minute duty cycle period specified for the weld-

ing processes.

Refer to Section 3.12 for how to set up for gouging.

Carbon electrodes have a range of specified operating current. Here are the normal sizes that would be in use

with a power source of this size, and the power source capability when used with these carbon electrode sizes

Electrode Size

Amps

Duty Cycle

6.5mm

300A

90%

400A

63%

8.0mm

350A

70%

450A

54%

9.5mm

450A

50%

550A

35%

Table 2-2: Electrode Size

A-11481

Figure 2-2: Gouging Current (AMPS)