Tweco 550i Transmig User Manual

Page 38

TRANSMIG 350i, 450i, 550i

INSTALLATION, OPERATION AND SETUP 3-18 Manual 0-5205

C. Fit the gas regulator and flowmeter to the gas cylinder then connect the gas hose from the rear of the

Wirefeeder to the flowmeter outlet.

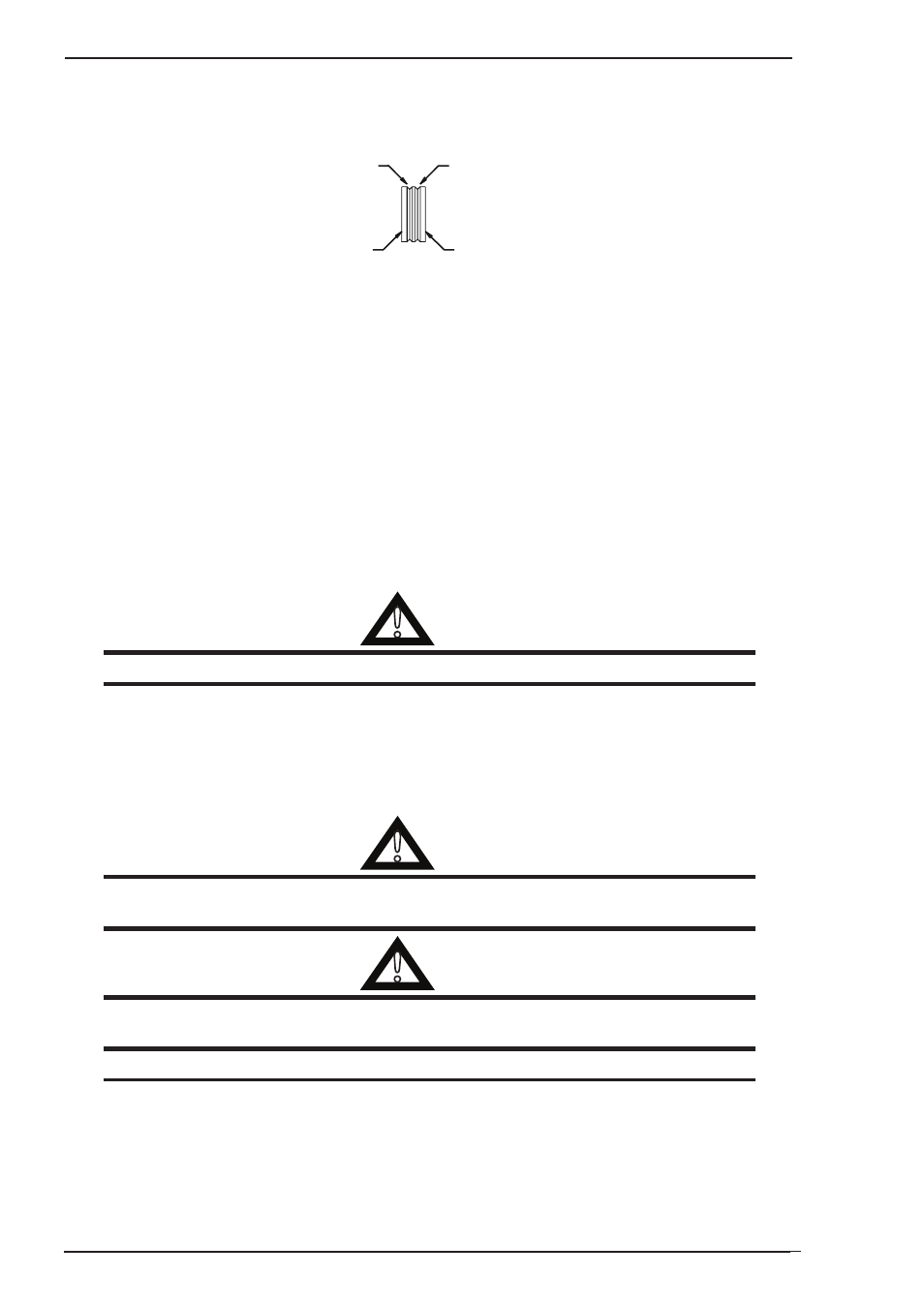

D. Dual groove feed rollers are supplied as standard. Select the roller required with the chosen wire size

marking facing outwards.

E. Fit the electrode wire spool to the wire reel hub. Ensure that the drive dog-pin engages the mating hole

in the wire spool. Push the 'R' clip into place to retain the wire spool securely. The electrode wire should

feed from the bottom of the spool.

F MIG Torch, EURO MIG Torch Connection

Fit the MIG Torch to the Wirefeeder by pushing the torch connector into the brass torch adaptor and screw-

ing the plastic torch nut clockwise to secure the torch to the torch adaptor. Remove the contact tip from

the torch handset.

TWECO style Torch Connection

Fit the MIG Torch to the Wirefeeder by pushing the torch connector into the brass torch adaptor and screw-

ing the hand nut clockwise to secure the torch to the torch adaptor. Remove the contact tip from the torch

handset. Attach the wirefeeder trigger wires to the MIG Torch.

G Lift up the wire feeder pressure levers and pass the electrode wire through the inlet guide, between the

rollers, through the centre guide, between the rollers, through the outlet guide and into the MIG torch.

!

WARNING

DO NOT WEAR GLOVES WHILE THREADING THE WIRE OR CHANGING THE WIRE SPOOL.

H. Lower the pressure levers and with the torch lead reasonably straight, feed the electrode wire through the

torch. Fit the appropriate contact tip, eg a 0.9mm tip for 0.9mm wire.

I Press the INCH button to feed the wire through the torch. (Only applicable to wirefeeders connected to the

10 pin socket. Wirefeeders connected to the 19 pin socket can only be inched from the wirefeeder itself if

that function is available.)

!

WARNING

If the Torch Trigger is used to feed wire through the torch, the electrode wire will be at welding

voltage potential whilst it is being fed through the wirefeeder system.

!

WARNING

Before connecting the work clamp to the work piece make sure the mains power supply is switched

off.

NOTE

Welding Setup Program Storage (10 programs) applies to MIG (10 pin only), Stick and Lift Tig modes.

GROOVE “B”

GROOVE “A”

GROOVE “A” SIZE

GROOVE “B” SIZE

Art # A-08739