Tweco 200 ACDC Arcmaster(Feb2006) User Manual

Page 55

49

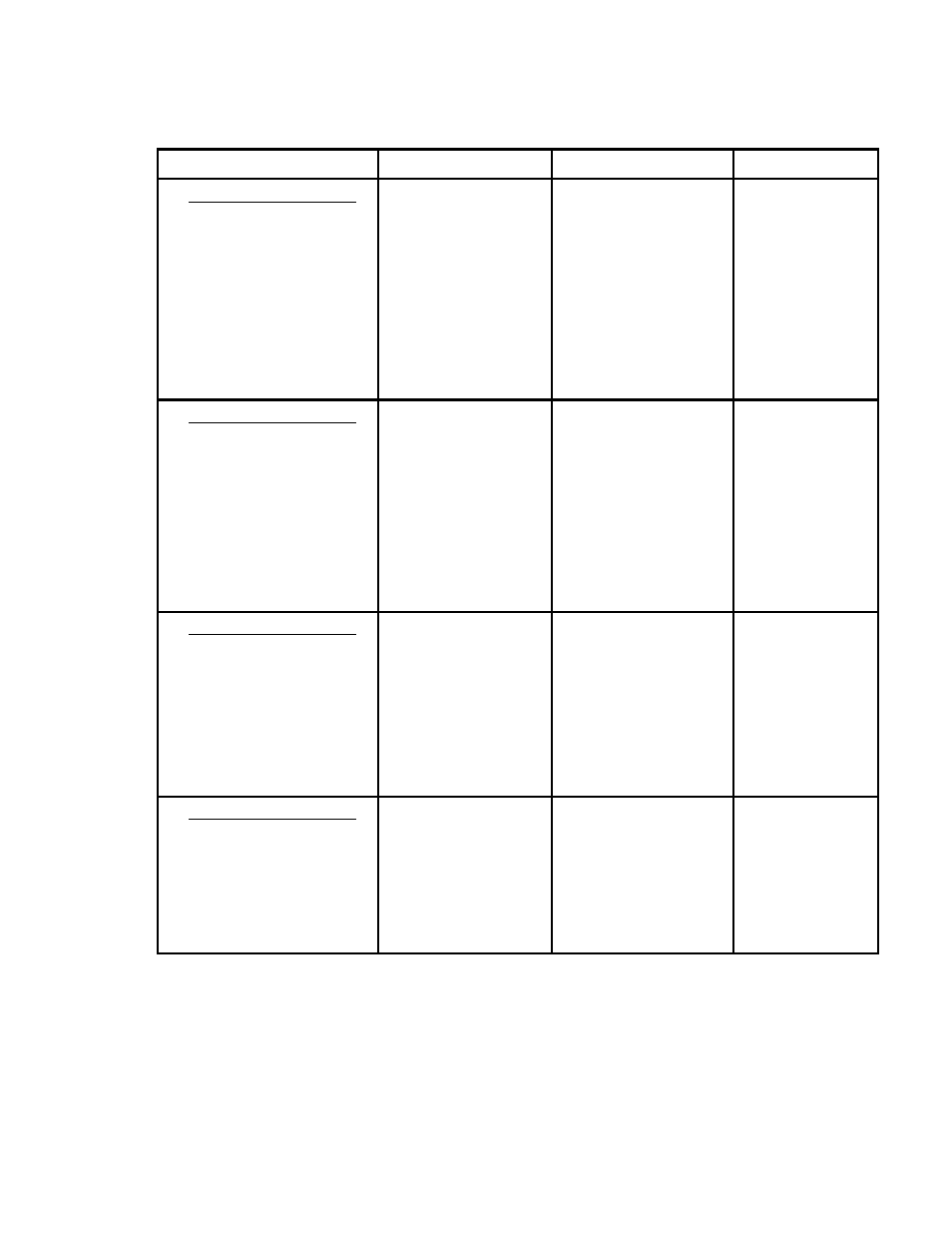

12.0 POWER SOURCE ERROR CODES

Description

Possible

Cause Remedy

Remarks

1 E01 error code displayed

Temperature sensor TH1

(protects IGBTs) is greater

than 80ºC for about 1

second.

A

B

C

The Welding Power

Source’s duty cycle

has been exceeded.

Fan ceases to

operate.

Air flow is restricted

by vents being

blocked.

A

B

C

Let Power Source cool

down then keep within

its duty cycle.

Have an accredited

Thermal Arc Service

Agent investigate.

Unblock vents then let

Power Source cool

down.

Weld current

ceases.

Buzzer sounds

constantly.

Fan operates at max

speed.

E01 resets when

TH1 decreases to

70ºC for about 30

seconds.

2 E02 error code displayed

Temperature sensor TH2

(protects secondary

diodes) is greater than

80ºC for about 1 second.

A

B

C

The Welding Power

Source’s duty cycle

has been exceeded.

Fan ceases to

operate.

Air flow is restricted

by vents being

blocked.

A

B

C

Let Power Source cool

down then keep within

its duty cycle.

Have an accredited

Thermal Arc Service

Agent investigate

Unblock vents then let

Power Source cool

down.

Weld current

ceases. Buzzer

sounds constantly.

Fan operates at max

speed. E02 resets

when TH2 ecreases

to 70ºC for about

30 seconds.

3 E03 error code displayed

Primary (input) current too

high.

A

B

Primary current is too

high because welding

arc is too long.

Mains supply voltage

is more than 10%

below nominal

voltage .

A

B

Reduce length of

welding arc.

Have an accredited

Thermal Arc Service

Agent or a qualified

electrician check for

low Mains voltage.

Weld current

ceases.

Buzzer sounds

constantly.

Switch machine

OFF then ON to

reset E03 error.

4 E04 error code displayed

Output voltage exceeds the

secondary voltage

specification.

TIG torch cable

and/or work lead are

too long or leads

are coiled.

Reduce the length of

the TIG torch cable

and/or work lead or

un-coiled leads.

Weld current

ceases.

Buzzer sounds

constantly.

Switch machine

OFF then ON to

reset E04 error.