Tweco 200 ACDC Arcmaster(Feb2006) User Manual

Page 26

20

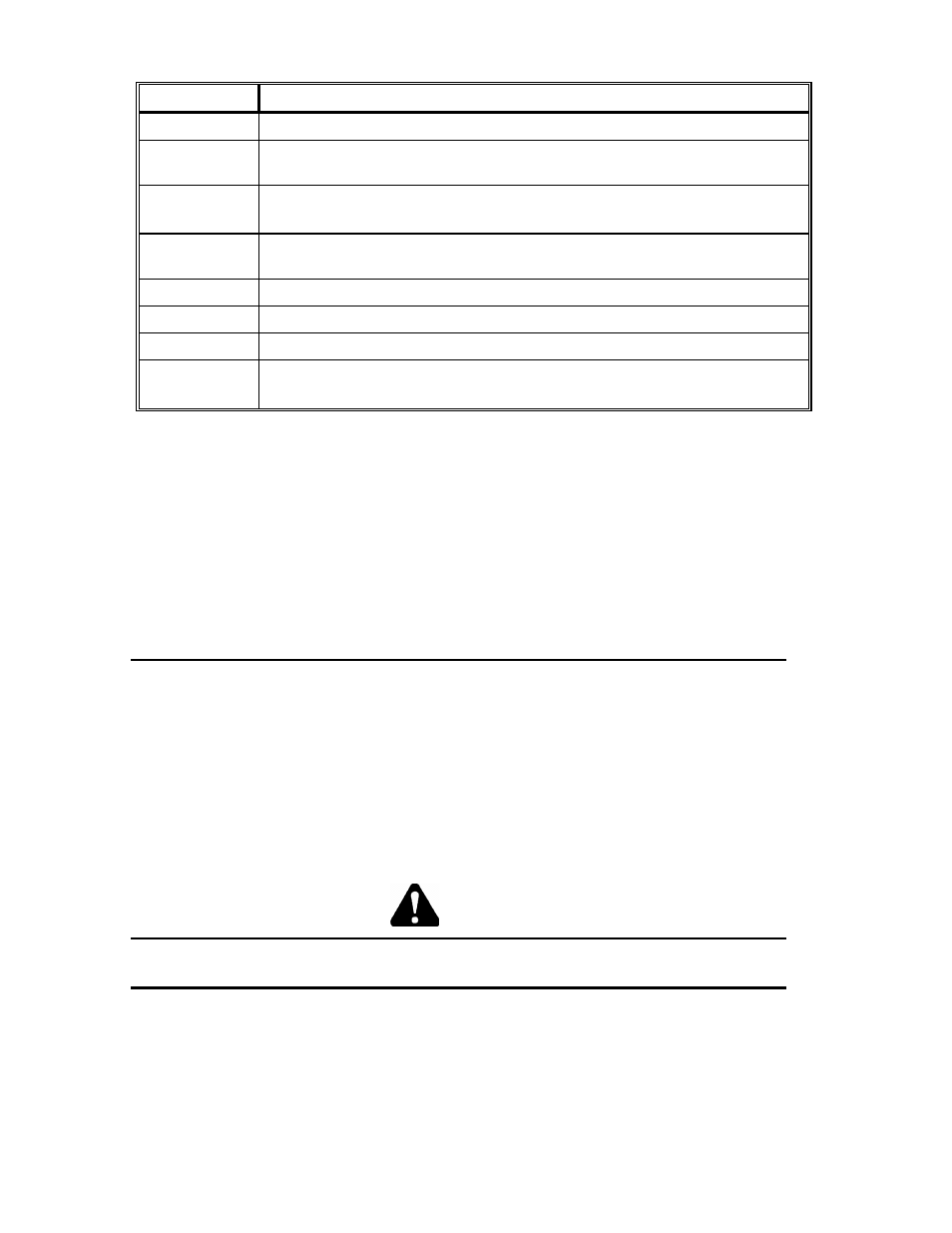

Socket Pin

Function

1 Earth

(Ground)

2

Torch Switch Input (24V) to energize weld current.

(connect pins 2 & 3 to turn on welding current)

3

Torch Switch Input (0V) to energize weld current

(connect pins 2 & 3 to turn on welding current)

4

Connect pin 4 to pin 8 to instruct machine that a remote current control device is

connected (12V DC supply)

5

5k ohm (maximum) connection to 5k ohm remote control potentiometer

6

Zero ohm (minimum) connection to 5k ohm remote control potentiometer

7

Wiper arm connection to 5k ohm remote control potentiometer

8

Connect pin 4 to pin 8 to instruct machine that a remote current control device is

connected (0V)

3

Positive Terminal

Welding current flows from the Power Source via heavy duty Dinse type terminal (Size 35-70). It is

essential, however, that the male plug is inserted and turned securely to achieve a sound electrical

connection.

4

Negative Terminal

Welding current flows from the Power Source via heavy duty Dinse type terminal (Size 35-70). It is

essential, however, that the male plug is inserted and turned securely to achieve a sound electrical

connection.

CAUTION 2

Loose welding terminal connections can cause overheating and result in the male plug being

fused in the bayonet terminal.

5

Gas Outlet

The Gas Outlet is a 5/8 18 UNF female gas fitting.

6

ON/OFF Switch

This switch connects the Primary supply voltage to the inverter when in the ON position. This enables

the Power Supply.

WARNING 6

When the welder is connected to the Primary supply voltage, the internal electrical components

may be at 240V potential with respect to earth.

7

Input Cable

The input cable connects the Primary supply voltage to the equipment.