Tweco 200 ACDC Arcmaster(Feb2006) User Manual

Page 38

32

7.0 BASIC TIG WELDING GUIDE

7.01 Explanation of “Fluttery Arc” when AC TIG Welding on Aluminum

The following will assist in understanding the phenomenon of Arc Flutter, also referred to as Arc Rectification.

The basic thesis is that the fluttering is caused by lack of oxide in the weld pool.

The oxide layer on the plate reduced the energy for electron emission. Electron emission from the weld pool

(DC+) causes the oxide layers to be disrupted, the so-called “cleaning action”. However once the cleaning

action has produced a mirror like surface weld pool the effect of the oxide layer is limited because the oxide

layer has dissipated. This makes electron emission from the weld pool more difficult and increases the chance

of arc instability.

This idea is supported by the observation that once fluttering starts it can be made to stop by working the

arc away from the mirror like weld pool to an area of oxide coated material. As soon as this is done the

arc settles back to a stable condition. So while the arc is “consuming” oxide coated plate the instability

does not occur. But once the arc is stationary, the pool becomes thoroughly “cleaned” by election

emission, the fluttering begins.

Tests conducted on various types of AC TIG power sources, Fluttery Arc is not confined to one type of power

source or it’s design, both conventional and inverter types suffer from the same problem.

AC TIG on aluminum

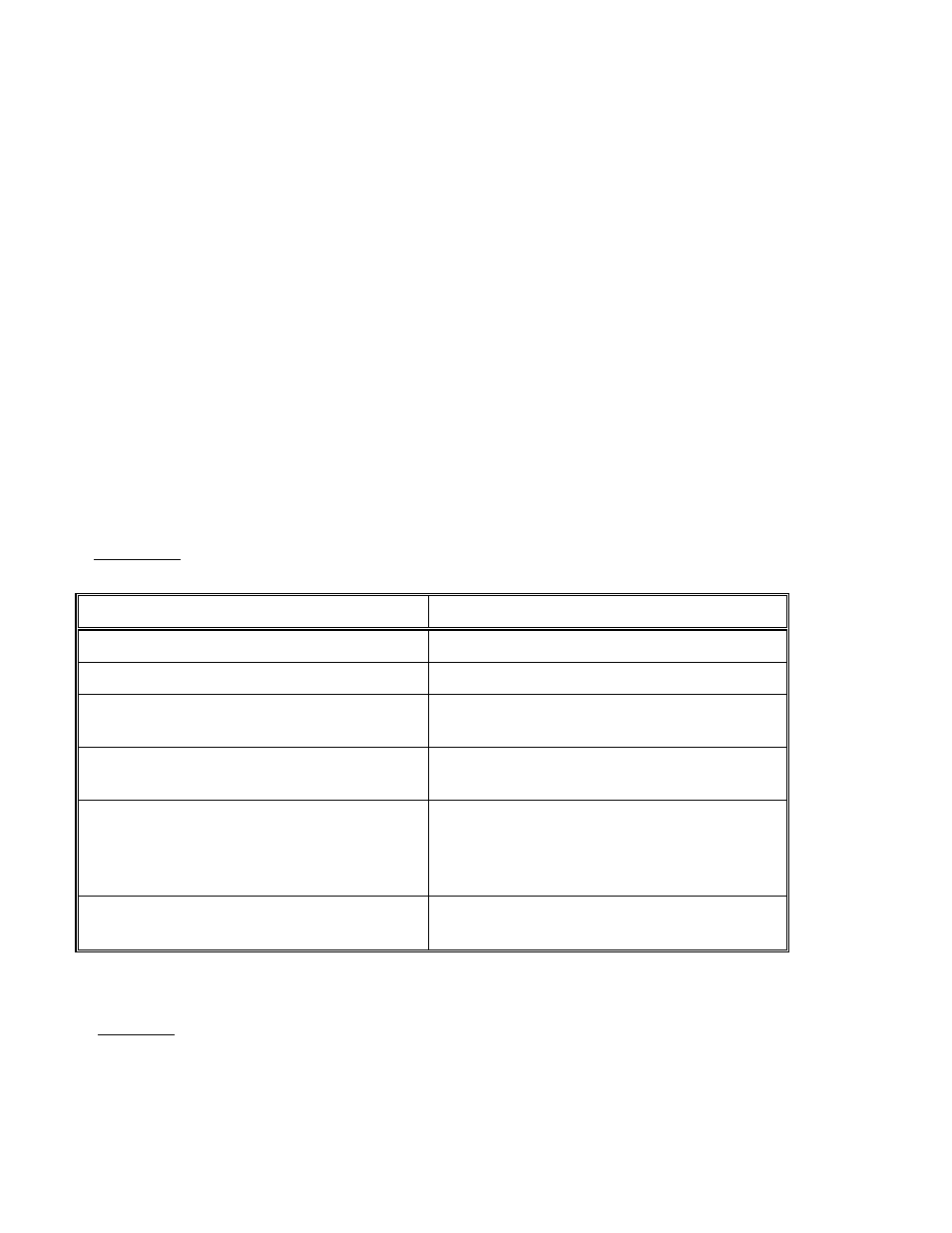

The Problem:

Arc appears unstable and pulses or flutters. i.e. appears to rapidly change welding current

.

Conditions that accentuate arc flutter:

Conditions that minimizes arc flutter:

• Cold work piece.

• Preheat the work piece.

• Very short arc length.

• Increase the arc length.

• Weld pool crater about 0.39” to 0.47”

(10 to 12mm) diameter.

• Introduce filler rod material to the weld

pool, which introduces oxides.

• Arc field in one spot to produce “mirror”

clean weld pool.

• Move the weld pool around to introduce

oxides to the weld pool.

• Increased cleaning action.

ie. Prolonged oxide emission from a

stationary weld pool increases the

likelihood of arc flutter.

• Decrease the cleaning action by turning the

WAVE BALANCE

to below 50% or move the

weld pool around.

• Accentuated when tungsten running near

its current capacity, i.e. molten ball on end.

• Use a larger diameter tungsten electrode.

Table 7 – Reduction of Arc Flutter

Conclusion:

Fluttery arc in AC TIG is a physical phenomenon independent of machine design.