Tweco 200 ACDC Arcmaster(Feb2006) User Manual

Page 33

27

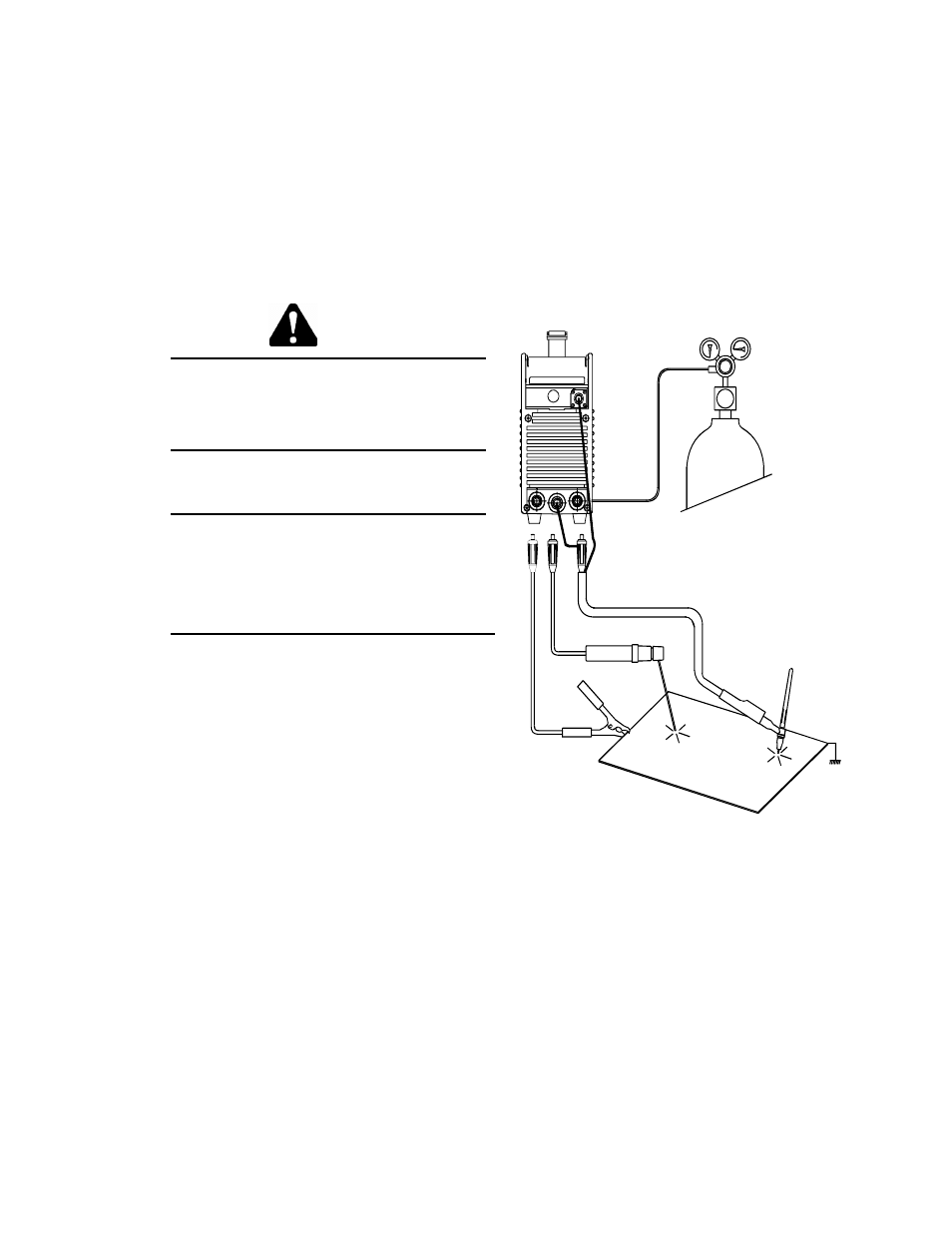

5.0 SET-UP FOR SMAW (STICK) AND GTAW (TIG)

Conventional operating procedures apply when using the Welding Power Source, i.e. connect work lead

directly to work piece and electrode lead is used to hold electrode. Wide safety margins provided by the coil

design ensure that the Welding Power Source will withstand short-term overload without adverse effects. The

welding current range values should be used as a guide only. Current delivered to the arc is dependent on the

welding arc voltage, and as welding arc voltage varies between different classes of electrodes, welding current

at any one setting would vary according to the type of electrode in use. The operator should use the welding

current range values as a guide, then finally adjust the current setting to suit the application.

WARNING 7

Before connecting the work clamp to the work

and inserting the electrode in the electrode

holder make sure the Primary power supply is

switched OFF.

CAUTION 3

Remove any packaging material prior to use.

Do not block the air vents at the front or rear

or sides of the Welding Power Source.

CAUTION 4

DO NOT change the Weld Mode or Weld

Process Mode until after POST-FLOW time

has finished.

Figure 6. 200 ACDC Set-up