Tweco 200 ACDC Arcmaster(Feb2006) User Manual

Page 37

31

6.02.03 Pulse Controls

The Pulse controls are used primarily to control heat input. Pulse offers a number of advantages

as follows:

1) Control puddle – size and fluidity (especially out of position).

2) Increase penetration

3) Travel speed control

4) Better consistent quality

5) Decreased distortion on lighter or thinner materials.

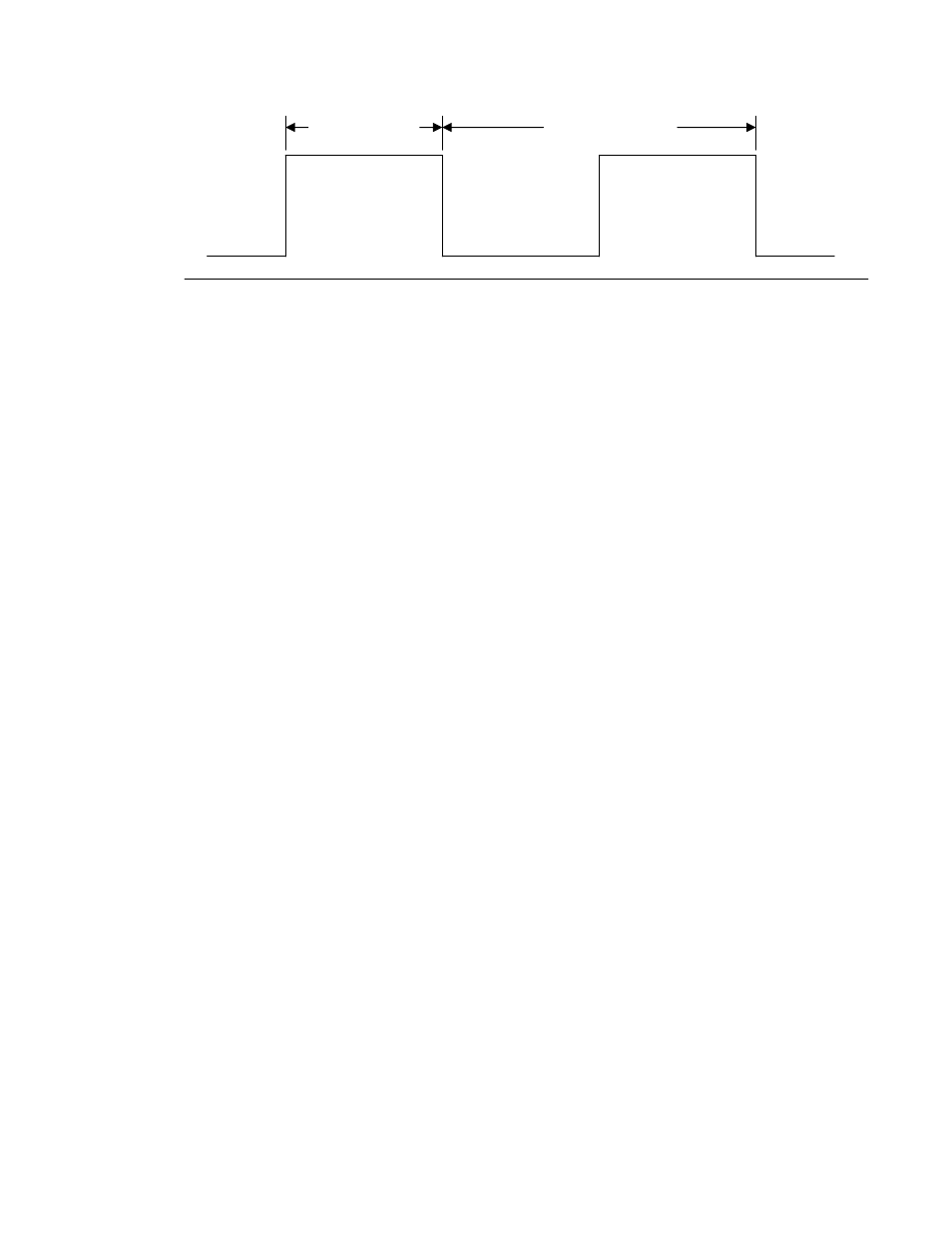

Pulse-current provides a system in which the welding current continuously changes between two levels. During

the periods of Peak current, heating and fusion takes place, and during the background (base) current periods,

cooling and solidification take place. Pulse Width is the time in one cycle the current remains at the peak

current setting. Pulse Frequency, measured in Hertz, is the number of cycles per second the current travels

between peak and background current settings. It is as if the foot rheostat were moved up and down to

increase and decrease the welding current on a regular basis. The faster you moved the foot rheostat up and

down the faster the frequency.

(Peak Current)

(Base)

Background

Current

(Pulse Width)

(Pulse Frequency)