Section 4: operation, 01 introduction, 02 functional overview – Tweco RC6010 User Manual

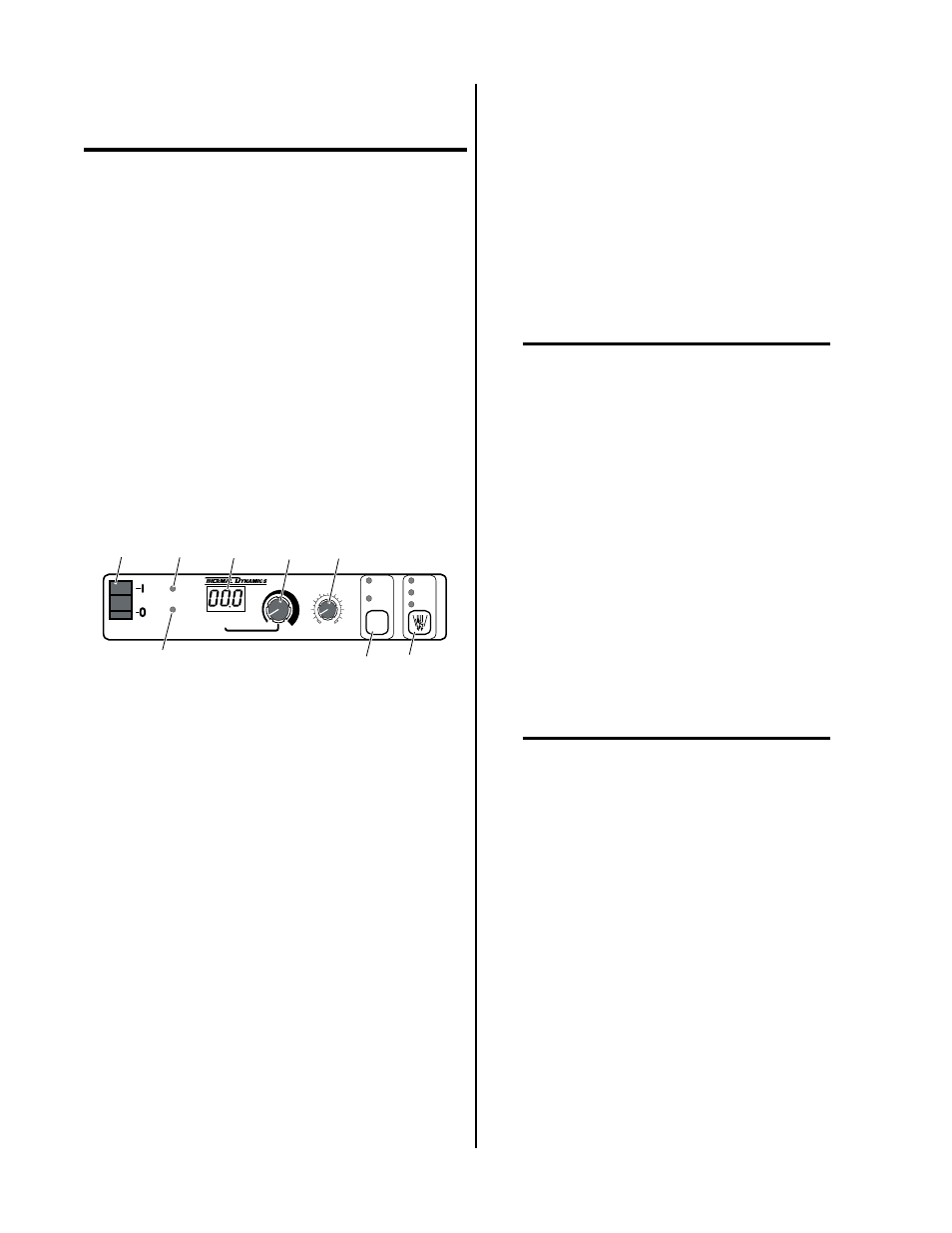

Page 25: 03 operating controls, Figure 4-1 front panel operating controls

Manual 0-2478

21

OPERATION

SECTION 4:

OPERATION

4.01 Introduction

This Section provides a description of the RC6010 Remote

Control Assembly followed by operating procedures.

4.02 Functional Overview

The RC6010 Remote Control Accessory extends the nec-

essary system controls away from the power supply and

is provided with standard machine torch systems.

There are connections available at the Remote Control

Accessory for CNC control, Standoff Control, and Plasma

Power Supply). The inputs and outputs at these connec-

tions allow the various parts of the system to be operated

at one station.

4.03 Operating Controls

OUTPUT AMPS

PLASMA

ENABLE

ON

START

REMOTE POWER SUPPLY CONTROL

CSD

(%)

0

25

75

100

50

TRAVEL

SPEED

125+

IPM

0-125

IPM

RUN

PURGE

SET

1

2

3

4

5

6

7

8

A-00682

Figure 4-1 Front Panel Operating Controls

1. PLASMA ENABLE (On/Off) Switch

Turns on contactor(s) in the Plasma Power Supply to

apply power to the Plasma Power Supply power and

control circuits when in the on (|) position. When the

switch is in the off (0) position the display will be blank

but some indicators may be ON.

2. ON Indicator

Yellow light indicates Plasma Power Supply is en-

abled.

3. START Indicator

Yellow light indicates Plasma Power Supply has re-

ceived start signal from Remote Control.

4. OUTPUT AMPS Meter

Displays actual output during cutting operation. Pre-

view mode displays expected output before starting

a cut according to the current setting. A decimal point

to the right of the display is lit whenever the meter is

in preview mode. All three decimal points remain lit

when displaying corner slowdown output or operat-

ing in corner slowdown mode.

5. Current Control Adjustment

Sets output current level.

6. CSD (%) Corner Slowdown Control Adjustment

Sets corner slowdown (CSD) output as a percentage

of main output.

7. TRAVEL SPEED Switch and Indicators

NOTE

This function used with TD-750 Systems Only.

Pushbutton used to select the pilot pulse rate and re-

start delay for the range of travel speed desired for

the operation. Each time the pushbutton is pressed

the travel speed indicators will toggle between 125+

IPM and 0-125 IPM speeds. The travel speed currently

selected is indicated by the indicator being turned ON.

8. Mode Selection Switch and Indicators

Pushbutton used to select the operating mode of the

system. Each time the pushbutton is pressed the mode

indicators will sequence through RUN, PURGE, and

SET. RUN mode is used for torch operation; PURGE

mode is used for purging the plasma gas line only;

SET mode is used to set the plasma and secondary

gas pressures and flows with Optional Gas Flow Con-

trol. The mode currently selected is indicated by the

indicator being turned ON.

NOTE

Mode cannot be switched from RUN mode during

cut operation.