Tweco Max 300 w-TD-750 User Manual

Page 52

APPENDIX

4

6

Man

ual 0-2557

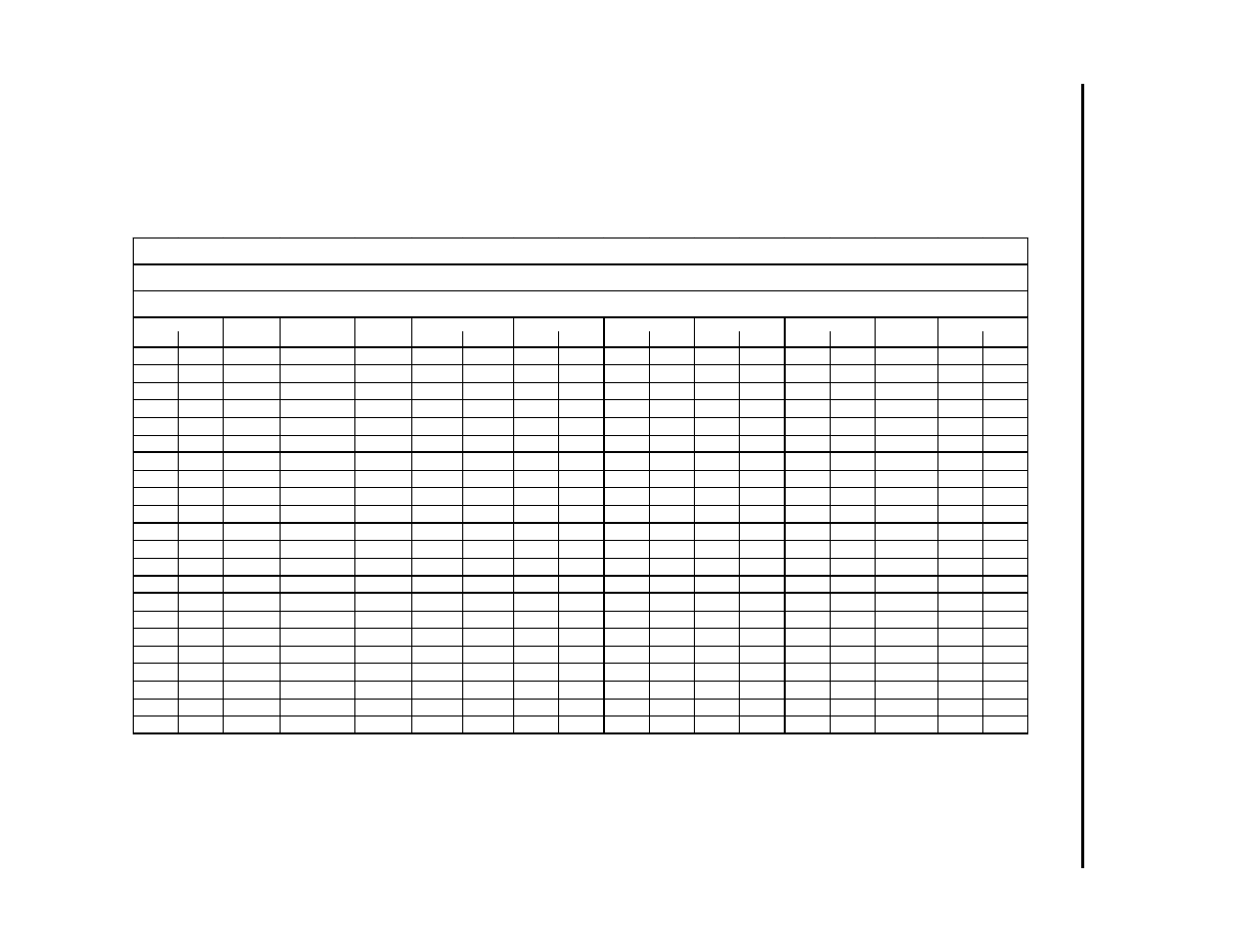

APPENDIX II:

CUTTING SPEED CHAR

TS FOR

TD-750

SYSTEMS (Contin

ued)

Air Plasma Cutting Speed Data Chart

Type Torch: Maximizer 300

Type Material: Mild Steel

Type Plasma Gas: Air

Type Secondary Gas: Air

Thickness

Tip

Output Volts

Amperage

Speed (Per Minute)

Standoff

Plasma Gas Press

Sec Gas Press

Total Flow (CFH)

Pierce

Pierce Height

Inches

mm

(Cat. No.)

(VDC)

(Amps)

Inches

Meters

Inches

mm

psi

bar

psi

bar

Plasma

Sec

Delay (Sec)

Inches

mm

1/8

3.18

9-6424

165

70

165

4.19

0.19

4.76

70

4.8

75

5.2

58

270

0

0.19

4.76

1/4

6.35

9-6424

170

70

80

2.03

0.19

4.76

70

4.8

75

5.2

58

270

0

0.19

4.76

3/8

9.53

9-6424

170

70

50

1.27

0.19

4.76

70

4.8

75

5.2

58

270

0.5

0.19

4.76

1/2

12.70

9-6424

175

70

25

0.64

0.19

4.76

70

4.8

75

5.2

58

270

0.75

0.19

4.76

3/4

19.05

9-6424

180

70

12

0.30

0.19

4.76

70

4.8

75

5.2

58

270

1

0.25

6.35

1

25.40

9-6424

190

70

7

0.18

0.19

4.76

70

4.8

75

5.2

58

270

1.5

0.25

6.35

1/8

3.18

9-6425

160

105

275

6.99

0.19

4.76

70

4.8

75

5.2

60

270

0

0.19

4.76

1/4

6.35

9-6425

160

105

125

3.18

0.19

4.76

70

4.8

75

5.2

60

270

0

0.25

6.35

3/8

9.53

9-6425

165

105

85

2.16

0.19

4.76

70

4.8

75

5.2

60

270

0.5

0.25

6.35

1/2

12.70

9-6425

165

105

50

1.27

0.19

4.76

70

4.8

75

5.2

60

270

0.5

0.25

6.35

3/4

19.05

9-6425

170

105

25

0.64

0.19

4.76

70

4.8

75

5.2

60

270

0.75

0.25

6.35

1

25.40

9-6425

178

105

15

0.38

0.19

4.76

70

4.8

75

5.2

60

270

1

0.38

9.53

1 1/4

31.75

9-6425

180

105

10

0.25

0.19

4.76

70

4.8

75

5.2

60

270

1.2

0.38

9.53

1 1/2

38.10

9-6425

182

105

6

0.15

0.19

4.76

70

4.8

75

5.2

60

270

1.5

0.38

9.53

1/4

6.35

9-6426

150

140

175

4.45

0.19

4.76

60

4.1

75

5.2

52

270

0

0.25

6.35

3/8

9.53

9-6426

150

140

100

2.54

0.19

4.76

60

4.1

75

5.2

52

270

0

0.25

6.35

1/2

12.70

9-6426

150

140

65

1.65

0.19

4.76

60

4.1

75

5.2

52

270

0

0.25

6.35

3/4

19.05

9-6426

150

140

45

1.14

0.19

4.76

60

4.1

75

5.2

52

270

0.5

0.25

6.35

1

25.40

9-6426

160

140

25

0.64

0.19

4.76

60

4.1

75

5.2

52

270

0.5

0.25

6.35

1 1/4

31.75

9-6426

165

140

18

0.46

0.19

4.76

60

4.1

75

5.2

52

270

0.75

0.38

9.53

1 1/2

38.10

9-6426

170

140

10

0.25

0.19

4.76

60

4.1

75

5.2

52

270

1

0.38

9.53

2

50.80

9-6426

175

140

5

0.13

0.19

4.76

60

4.1

75

5.2

52

270

1.5

0.38

9.53