07 machine torch operation – Tweco Max 300 w-TD-750 User Manual

Page 28

OPERATION

22

Manual 0-2557

4.07 Machine Torch Operation

A. Cutting With Machine Torch

The machine torch can be activated by remote control

pendant or by a remote interface device such as CNC.

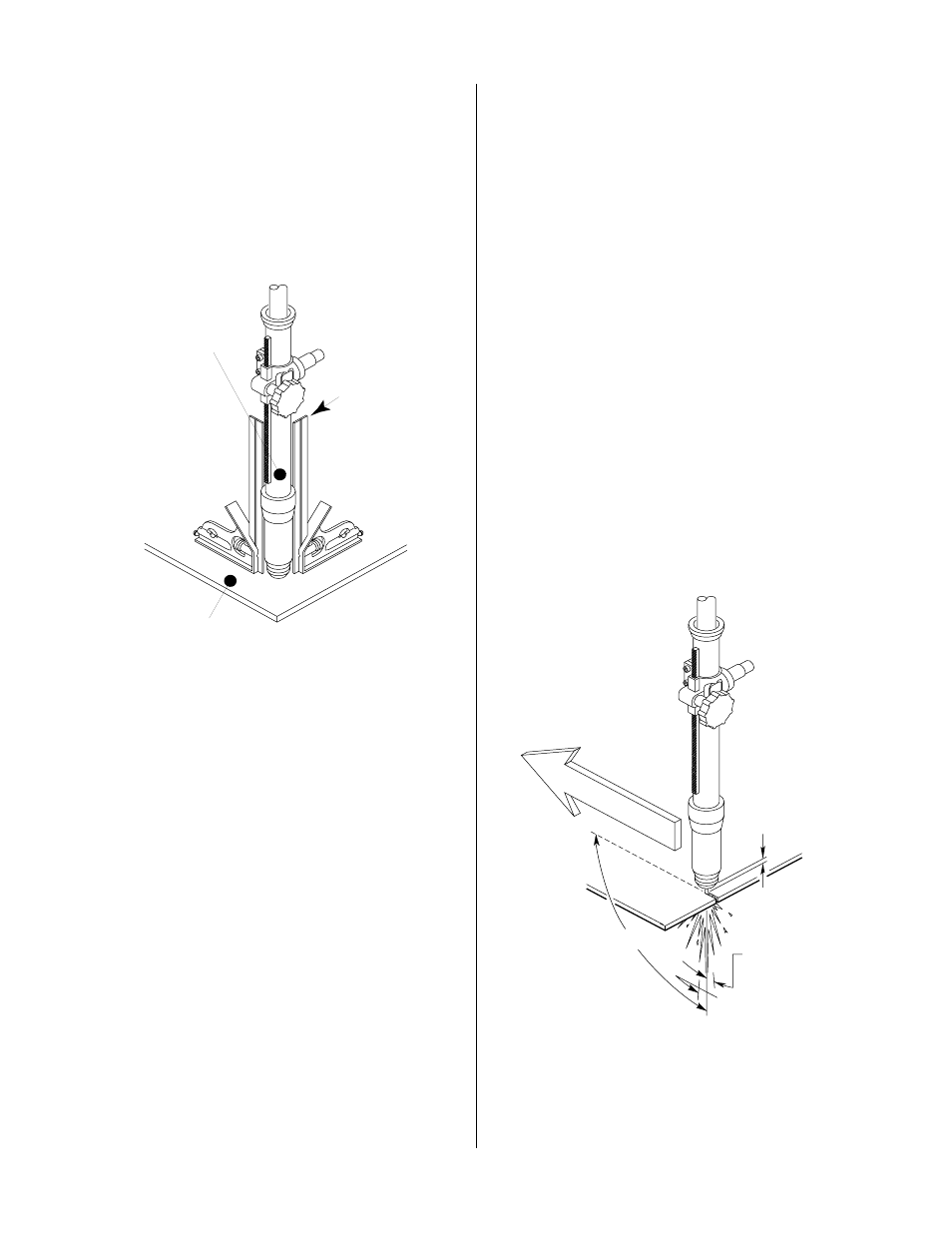

1. Use a square to check that the torch is perpendicu-

lar to the workpiece to obtain a clean, vertical cut.

Rack and

Pinion Mounting

Assembly

Square

A-00660

Workpiece

Figure 4-6 Checking Alignment

2. To start a cut at the plate edge, position the center

of the torch along the edge of the plate (refer to

Figure 4-7)

3. The machine torch can be activated by the remote

operator control panel, remote control pendant, or

by remote interface device such as CNC. After a

two second gas purge, the pilot arc will start. The

pilot arc will stay on as long as the torch is acti-

vated.

4. With the pilot arc on, the main cutting arc will be

established when the torch is brought within 1/8 -

3/8 in (3 - 10 mm) of the workpiece. If the cutting

arc is interrupted and the torch is still activated,

as when cutting expanded metal, the pilot arc will

automatically restart (see Auto-Restart Options in

the Control & Power Components Operating

Manual). De-activating the torch will shut off ei-

ther the pilot or main arc, depending on the mode

of operation.

5. Cut with a standoff of 1/8 - 3/8 in (3 - 10 mm) from

the work. The torch should be held perpendicu-

lar to the workpiece while cutting. Start cutting

slowly and adjust cutting speed for optimum cut-

ting performance. Refer to Section 4.09, Recom-

mended Cutting Speeds, for typical cutting speeds

for various materials and material thicknesses.

B. Travel Speed

Proper travel speed is indicated by the trail of the arc

which is seen below the plate ( Figure 4-7). The arc

can be one of the following:

1. Straight Arc

A straight arc is perpendicular to the workpiece

surface. This arc is generally recommended for

the best cut using air plasma on stainless or alu-

minum.

2. Leading Arc

The leading arc is directed in the same direction

as torch travel. A five degree leading arc is gener-

ally recommended for air plasma on mild steel.

3. Trailing Arc

The trailing arc is directed in the opposite direc-

tion as torch travel.

A-00662

Standoff

Distance

Straight Arc

Trailing Arc

Leading Arc

Direction of Torch Travel

Shown with

Rack and Pinion

Mounting Assembly

Figure 4-7 Machine Torch Operation