Tweco Max 300 w-TD-750 User Manual

Page 26

OPERATION

20

Manual 0-2557

C. Bevel Angle

The angle between the surface of the cut edge and a

plane perpendicular to the surface of the plate. A per-

fectly perpendicular cut would result in a 0° bevel

angle.

D. Top-Edge Rounding

Rounding on the top edge of a cut due to wearing

from the initial contact of the plasma arc on the work-

piece.

E. Bottom Dross Build-up

Molten material which is not blown out of the cut area

and re-solidifies on the plate. Excessive dross may

require secondary clean-up operations after cutting.

F. Kerf Width

The width of the cut (or the width of material removed

during the cut).

G. Top Spatter (Dross)

Top Spatter or dross on the top of the cut caused by

slow travel speed, excess cutting height, or cutting tip

whose orifice has become elongated.

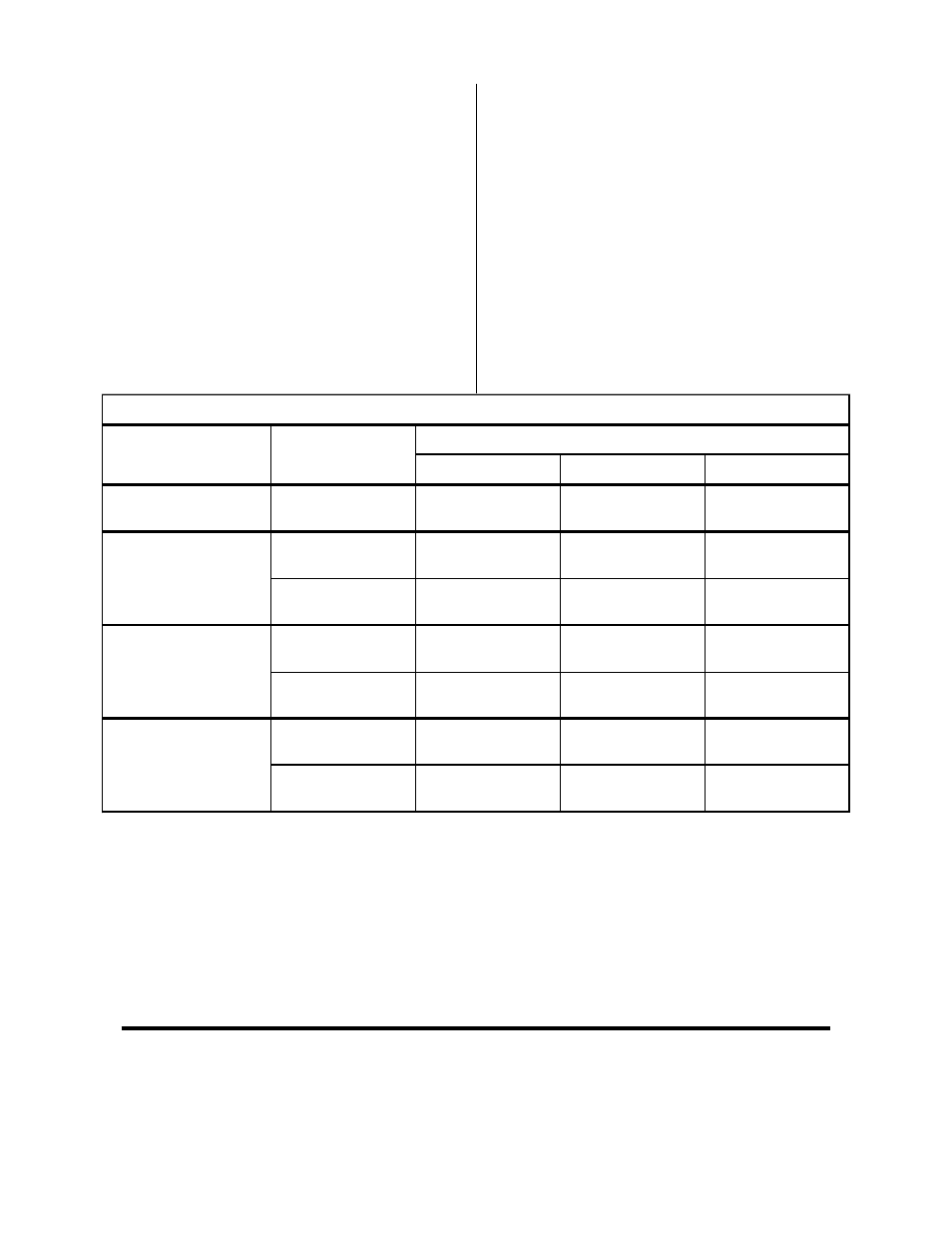

H. Various Materials and Thicknesses

The following table defines the cut quality on various

materials and thicknesses:

Typical Cut Quality on Various Materials

Type of Material

Type of Gases

Material Thickness

Carbon Steel

Stainless

Aluminum

Air Plasma and

Air Secondary

Gauge to 2 inches

(Gauge to 50.8 mm)

Good

Good

Good

Gauge to 1/4 inch

(Gauge to 6.4 mm)

NR

Good

Good

1/4 to 1 inch

(6.4 to 25.4 mm)

NR

Excellent

Good - Excellent

1/4 to 1/2 inch

(6.4 to 12.7 mm)

NR

NR

Excellent

1/2 to 2 inches

(12.7 to 50.8 mm)

NR

Excellent

Excellent

Gauge to 3/8 inch

(Gauge to 9.5 mm)

Good

NR

NR

3/8 to 2 inches

(9.5 to 50.8 mm)

Excellent

NR

NR

Oxygen Plasma and

Air Secondary

Nitrogen Plasma and

Water Secondary

Ar/H2 Plasma and

N2 or CO2 Secondary

Description of Cut Characteristics:

Excellent -

Minimum bevel (0 - 4°), minimum kerf (2 x tip orifice diameter), little or no dross, smooth cut surface.

Good -

Slight bevel (0 - 10°), slightly wider kerf (2-1/2 x tip orifice diameter), some dross (easily removed), medium-

smooth cut surface, slight top edge rounding.

Fair - Excessive bevel (over 10°), wide kerf (over 2-1/2 x tip orifice diameter), medium to heavy dross, rough cut

surface, top edge rounding.

NR -

Not Recommended.

NOTE

Cut quality depends heavily on set-up and parameters such as torch standoff, alignment with the workpiece, cutting

speed, gas pressures, and operator ability.