08 torch and leads troubleshooting – Tweco Max 300 w-TD-750 User Manual

Page 39

Manual 0-2557

33

SERVICE

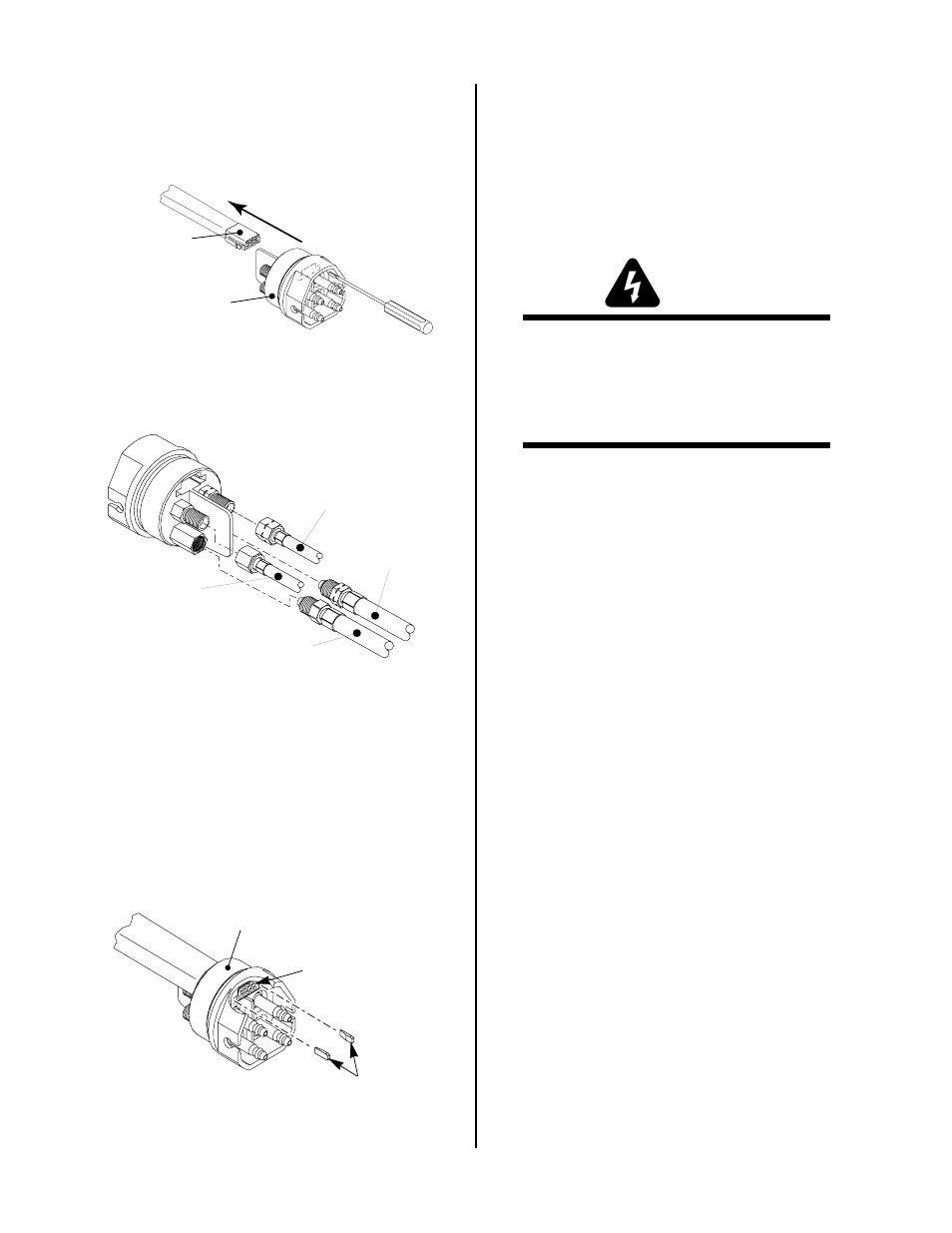

4. Using a small screwdriver, gently push in the tabs

on the side of the signal connector plug towards

the quick disconnect body. Carefully push the con-

nector out through the back of the quick discon-

nect body.

Signal Pin

Connector

Quick Disconnect

Body

A-00265

Figure 5-10 Removing The Signal Connector Plug

5. Disconnect the plasma (+), secondary, coolant sup-

ply (-) and coolant return fittings.

A-00267

Secondary

Connection

Plasma (+)

Connection

(LH Threads)

Coolant Return

Connection

(LH Threads)

Coolant Supply (-)

Connection

Figure 5-11 Disconnecting Leads

C. Reassembling Quick Disconnect Fitting

1. Connect the plasma (+), secondary, coolant supply

(-) and coolant return fittings to the quick discon-

nect body.

2. Insert the signal connector plug in the quick dis-

connect body and install the two white locking tabs

on both sides. The bevel must be towards the sig-

nal connector.

Signal Pin

Connector

Quick Disconnect

Body

A-00273

White Tabs

Figure 5-12 Installing White Locking Tabs

3. Slide the protective boot down onto the quick dis-

connect body.

4. Tighten the three mounting screws to secure the

protective boot onto the quick disconnect body.

5.08 Torch And Leads

Troubleshooting

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light on the front panel of the Con-

trol Module is ON.

A. Checking Center Insulator

1. Remove the shield cup, tip, gas distributor, and

electrode from the torch.

2. Disconnect the torch leads from the power supply

to isolate the torch from power supply circuits.

3. Using an ohmmeter (set to 10K or higher), check

for continuity between the positive and negative

torch quick disconnect fittings.

If infinite resistance (no continuity) is found the

center insulator is okay. Proceed to paragraph B,

Checking Pilot and Switch Control Wires.

If there is continuity between the two torch quick

disconnect fittings proceed to Step 4.

4. Remove the torch head from the leads (refer to Sec-

tion 5.06, Servicing Machine TorchComponents).

5. With the torch head disconnected from the leads,

measure the resistance between negative cathode

body of the torch head (where the electrode seats)

and the positive anode body of the torch head (the

outer threads where the shield cup seats).

Infinite resistance (no continuity) should be mea-

sured between negative and positive sections of

the torch head.

If any current can flow through the center insula-

tor, the torch head is faulty and must be replaced.

If the torch head is okay, the problem is in the leads

or quick disconnect assembly. Proceed to Step 6.

6. Slide the quick disconnect body, boot, and retain-

ing ring back (refer to Section 5.08, Servicing Torch

Leads Components).