Tweco CutMaster 101 with SL100SV User Manual

Page 54

OPERATION

4-14

Manual 0-4642

4

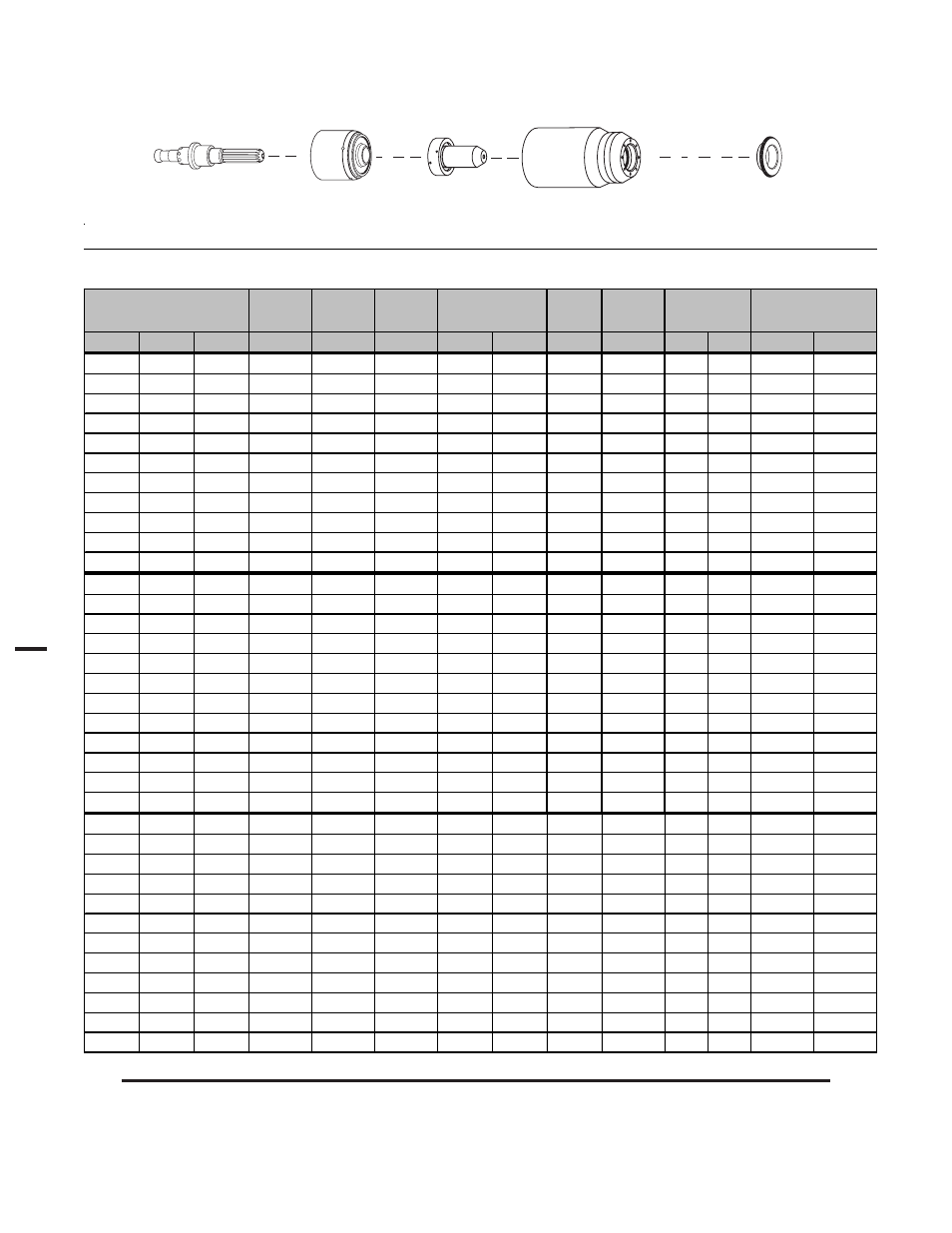

4.09 Cutting Speed Chart: Mild Steel, SL100 Torch with Exposed Tip

NOTES

* Gas pressure shown is for torches with leads up to 25' / 7.6 m long. For 50' / 15.2 m leads, increase pressure by 5 psi / 0.34 bar.

This information represents realistic expectations using recommended practices and well - maintained systems.

Actual speeds may vary up to 50% from those shown.

Electrode Start Cartridge Tip Shield Cup Body Shield Cap, Deflector

9-8215 9-8213 9-8237 9-8243

Art # A-04203

Torch: SL100 with Exposed Tip and Deflector

Power Supply: CutMaster 101 Automated

Tip

Current

Plasma

Press.*

Pierce

Time

Arc

voltage

In

GA

mm

Cat. #

Amps

PSI

In

mm

SEC

Volts

in

mm

IPM

mm/min

0.036

20

0.91

8-8208

40

65

0.188

4.8

0.00

96

0.19 4.80

341

8661.4

0.051

1.30

8-8208

40

65

0.188

4.8

0.00

97

0.19 4.80

300

7620

0.060

16

1.52

8-8208

40

65

0.188

4.8

0.10

98

0.19 4.80

265

6731

0.075

14

1.91

8-8208

40

65

0.188

4.8

0.30

100

0.19 4.80

190

4826

0.135

10

3.43

8-8208

40

65

0.188

4.8

0.40

101

0.19 4.80

120

3048

0.141

3.58

8-8208

40

65

0.188

4.8

0.50

102

0.19 4.80

112

2844.8

0.188

4.78

8-8208

40

65

0.188

4.8

0.60

107

0.19 4.80

60

1524

0.250

6.35

8-8208

40

65

0.188

4.8

1.00

111

0.19 4.80

40

1016

0.375

9.53

8-8208

40

65

NR

NR

NR

119

0.19 4.80

19.7

500.38

0.500

12.70

8-8208

40

65

NR

NR

NR

123

0.19 4.80

11.1

281.94

0.625

15.88

8-8208

40

65

NR

NR

NR

127

0.19 4.80

6

152.4

0.060

16

1.57

9-8210

60

70

0.188

4.8

0.00

110

0.19 4.80

293

7442.2

0.075

14

1.91

9-8210

60

70

0.188

4.8

0.10

110

0.19 4.80

288

7315.2

0.120

11

3.05

9-8210

60

70

0.188

4.8

0.10

111

0.19 4.80

273

6934.2

0.135

10

3.43

9-8210

60

70

0.188

4.8

0.10

111

0.19 4.80

215

5461

0.141

3.58

9-8210

60

70

0.188

4.8

0.15

112

0.19 4.80

177.6

4511.04

0.188

4.78

9-8210

60

70

0.188

4.8

0.20

114

0.19 4.80

137

3479.8

0.250

6.35

9-8210

60

70

0.188

4.8

0.30

116

0.19 4.80

82.4

2092.96

0.375

9.53

9-8210

60

70

0.188

4.8

0.50

118

0.19 4.80

42.4

1076.96

0.500

12.70

9-8210

60

70

0.188

4.8

0.75

119

0.19 4.80

26.3

668.02

0.625

15.88

9-8210

60

70

NR

NR

NR

127

0.19 4.80

17.4

441.96

0.750

19.05

9-8210

60

70

NR

NR

NR

126

0.19 4.80

16

406.4

1.000

25.40

9-8210

60

70

NR

NR

NR

128

0.19 4.80

12

304.8

0.047

18

1.19

9-8211

80

65

0.188

4.8

0.05

98

0.19 4.80

289

7340.6

0.120

11

3.05

9-8211

80

65

0.188

4.8

0.05

100

0.19 4.80

216

5486.4

0.135

10

3.43

9-8211

80

65

0.188

4.8

0.10

101

0.19 4.80

180

4572

0.188

4.78

9-8211

80

65

0.188

4.8

0.20

102

0.19 4.80

143

3632.2

0.250

6.35

9-8211

80

65

0.188

4.8

0.30

107

0.19 4.80

102.4

2600.96

0.375

9.53

9-8211

80

65

0.188

4.8

0.40

111

0.19 4.80

48

1219.2

0.500

12.70

9-8211

80

65

0.188

4.8

0.60

113

0.19 4.80

32.6

828.04

0.625

15.88

9-8211

80

65

0.188

4.8

0.75

116

0.19 4.80

24

609.6

0.750

19.05

9-8211

80

65

NR

NR

NR

121

0.19 4.80

18

457.2

0.875

22.23

9-8211

80

65

NR

NR

NR

126

0.19 4.80

14

355.6

1.000

25.40

9-8211

80

65

NR

NR

NR

132

0.19 4.80

10

254

1.250

31.75

9-8211

80

NR

NR

NR

136

0.19 4.80

2

50.8

Material: Mild Steel

Table: Dry

Gas: Compressed Air

Recommended

Travel Speed

Stand-off

Height

Pierce Height

Material thickness