tekmar 423 Universal Reset Module User Manual

Page 22

© 2007

D 423 - 08/07

22 of 36

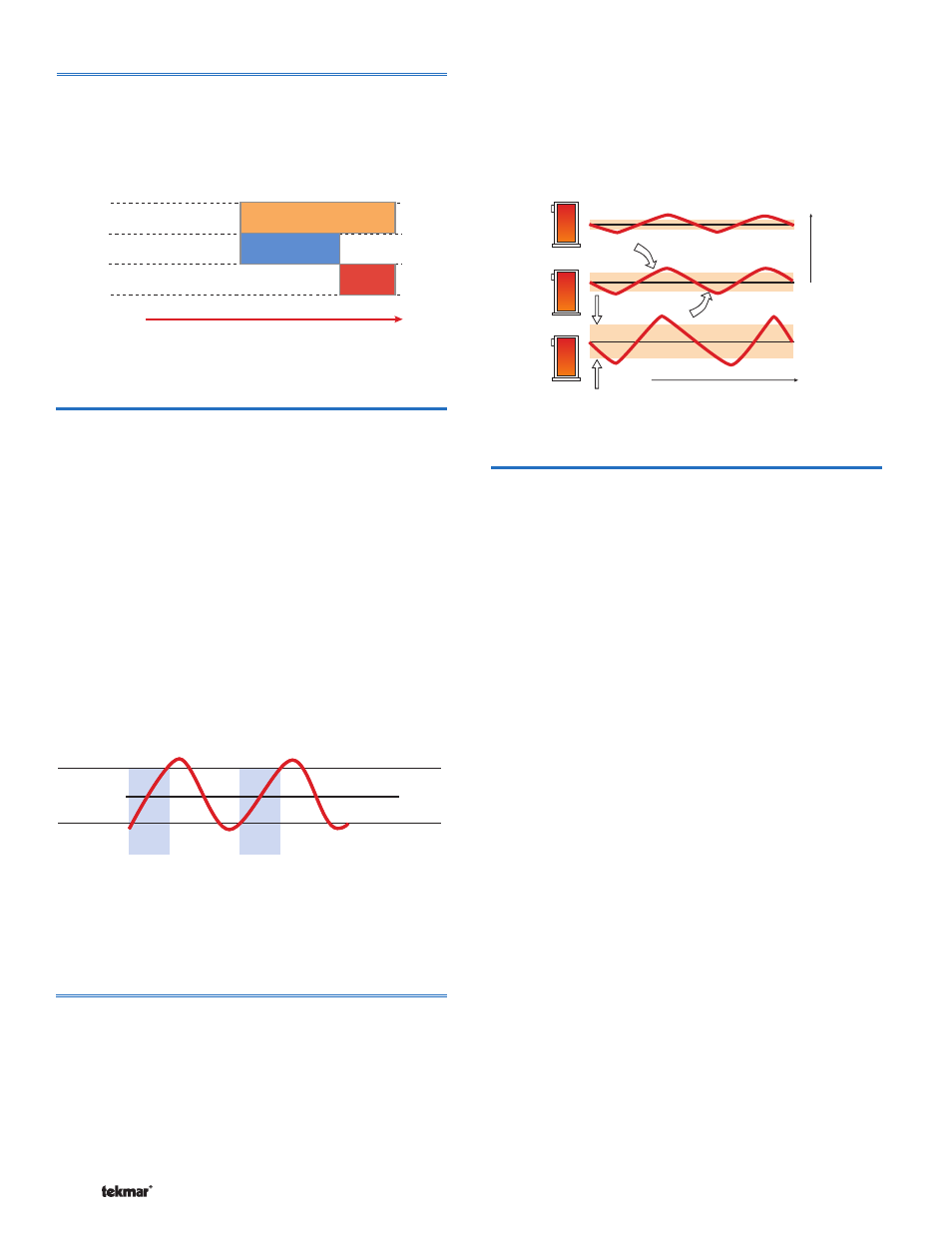

Boiler Fire Delay

The Boiler Fire Delay is the time delay that occurs between

the time that the control closes the boiler contact to fire the

boiler and when the burner fires.

•

• Locate the Boiler Fire Delay setting in the Adjust Menu.

Boiler Contact Closed

Time

Fire Delay

Burner On

On-Off Boiler(s) Operation

If the heat source is an On-Off Boiler(s), the Boil On-Off / Mod

DIP switch must be set to On-Off.

Differential

An on / off heat source must be operated with a differential

in order to prevent short cycling. With the control, either

a fixed or an auto differential may be selected. The boiler

differential is divided around the boiler target temperature.

The first stage contact closes when the supply water

temperature is 1/2 of the differential setting below the boiler

target temperature. The second stage is operated if the first

stage is unable to bring the supply water temperature up to

the boiler target temperature at a reasonable rate. As the

supply temperature reaches 1/2 of the differential above

the boiler target temperature, the stages are staged off.

•

• Locate the Boiler Differential setting in the Adjust Menu.

Differential = 10°F (6°C)

Target + 1/2 Differential

Target – 1/2 Differential

Target

165°F (74°C)

160°F (71°C)

155°F (68°C)

Boiler

On

Boiler

On

Fixed Differential

If the user desires to have a fixed differential, this is set

using the Boiler Differential setting in the Adjust Menu.

Stage Delay

The Stage Delay is the minimum time delay between the

firing of the first stage and the second stage. After this

delay has expired the control can fire the second stage if it

is required. This setting can be adjusted manually or set to

an automatic setting. When the automatic setting is used,

the control determines the best stage delay based on the

operation of the system.

•

• Locate the Stage Delay setting in the Adjust Menu.

Auto Differential

In order to decrease temperature swings and increase boiler

efficiency, the Auto Differential feature automatically changes

the on / off differential of the boiler based on the heating

load. As the load increases, the differential will decrease to

minimize temperature swings. As the load decreases, the

differential will increase to prevent short cycling.

Off

Differential

Time

Heating Load

On

Modulating Boiler Operation

The 423 can operate up to two modulating boilers. This

requires the use of the Mod 1 (dc) and Mod 2 (dc) outputs

on the 423.

To operate modulating boilers, the Boil On-Off / Mod DIP

switch must be set to Mod. The control operates each boiler

by first closing the stage contact to allow the modulating

boiler to go through the ignition sequence (the stage

contact may not be required on all modulating boilers).

Then, a 0-10 V (dc) analog signal is used to modulate the

boiler firing rate from the Minimum Modulation setting using

Proportional, Integral and Derivative (PID) logic in order

to satisfy the boiler target temperature. The second stage

is operated if the first stage is unable to bring the supply

water temperature up to the boiler target temperature at a

reasonable rate.

Modulating boilers require all the same settings as on-off

boilers in addition to the settings below.

Modulating Boiler Differential

Modulating boilers must be operated with a differential

while operating in low fire. The boiler differential is divided

around the boiler target temperature. The boiler burner

ignites at low fire when the supply water temperature is

1/2 of the Boiler Differential setting below the boiler target

temperature. The boiler is shut off in low fire as the supply

temperature reaches at least 1/2 of the differential above

the boiler target temperature. With the control, either a fixed

or an auto differential may be selected.

When the boilers are modulating above low fire, the differential

does not apply. Instead, the modulation output signal is

determined using Proportional, Integral and Derivative (PID)

logic in order to satisfy the boiler target temperature.