tekmar 371 House Control User Manual

Page 7

7

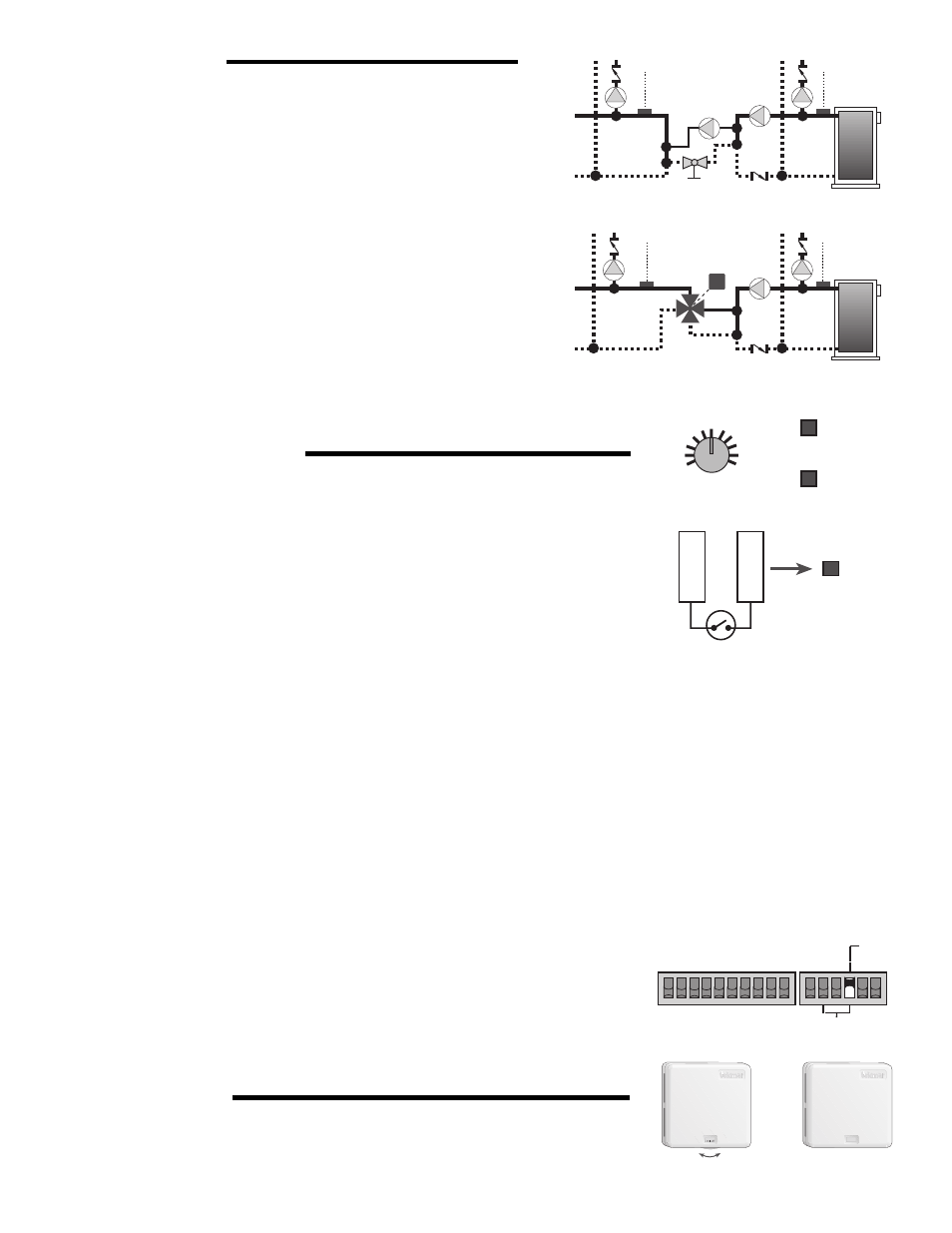

MIXING OPERATION

The 371 can supply a lower water temperature to part of the heating

system by varying the speed of an injection pump or modulating a mixing

valve. See Essay E 021 for more information. An outdoor reset strategy

is used with indoor temperature feedback from each of the mixing zones.

Boiler Protection

When the boiler is fired and the boiler supply temperature is below the

Min. Boiler Supply dial setting, the 371 turns on the Minimum Boiler

light and reduces the heating load on the boiler. During this warm up

period, the mixing device is operated at low outputs and some of the

zones may be prevented from operating.

System Maximum Supply / Setpoint Supply

The 371 has a

Max. Supply dial that can be used to set an upper limit

to the mixed supply water temperature. If this supply water tempera-

ture approaches the

Max. Supply dial setting, the 371 turns on the

Maximum Supply light and reduces the speed of the injection pump or

closes the mixing valve.

If the

Setpnt DIP switch is set to Mixing and setpoint operation is required, the 371 controls

the variable speed injection pump or the mixing valve in order to increase the mixed

supply water temperature to the

Setpnt dial setting.

DOMESTIC HOT WATER (DHW)

The DHW tank requests heat from the 371 through a DHW Demand. Whenever 120 V (ac)

is applied to the

DHW Dem (23) terminal on the 371, the control registers a DHW Demand

and turns on the

DHW Demand light. An aquastat, setpoint control or other switching device

can be used to generate a DHW Demand by wiring the line voltage signal through the

switching device and into the

DHW Dem terminal.

The 371 does not turn on the boiler system pump (P1) when DHW is required, therefore

piping a DHW tank to operate through a zone valve will increase wiring complexity.

DHW Supply Temperature

During DHW operation, the 371 targets a boiler water temperature of at least 180

°

F (82

°

C).

DHW Priority

The 371 is designed to provide DHW priority at all times. When a DHW demand is present, the control closes the contacts between

Power L — DHW Pmp (4 and 22) and turns on the DHW pump. The boiler system pump (P1) and the boiler zone relays are turned

off until the boiler water temperature is greater than 170

°

F (77

°

C).

DHW Post Purge

When the DHW Demand is removed and none of the zones require heat, the 371 turns off the boiler but continues to run the DHW

pump. This purges some residual heat from the boiler. The 371 allows a maximum Post Purge time of 4 minutes. If the boiler supply

temperature drops below 150

°

F (66

°

C) or below the

Min. Boiler Supply dial setting, the 371 stops the DHW Post Purge.

DHW Mixing Purge

If some of the zones require heat, the 371 performs a DHW Mixing Purge. During the Mixing Purge period, the 371 simultaneously

operates the DHW and heating systems. The 371 allows a maximum Mixing Purge period of 2 minutes for fast acting zone valves

and pumps and a longer purge period for thermal motor zone valves. The actual length of the purge period is dependent on the boiler

supply water temperature. At the end of the Mixing Purge period, the

DHW Pmp relay is turned off but the system pumps (P1 and

P2) and zone relays continue to operate.

DHW Setback

The

DHW during UnOcc. DIP switch selects whether DHW setback is desired while the

371 is in UnOccupied mode. If the

DHW during UnOcc. DIP switch is set to Off, the DHW

Demand is ignored during the UnOccupied period. However, if

Optimum Start is selected,

the 371 will respond to the DHW Demand in the last hour of the UnOccupied mode. This

will generally ensure that the DHW storage tank is up to temperature by the time the

Occupied period begins. If the DIP switch is set to

DHW during UnOcc., the 371 responds

to the DHW Demand at all times.

ZONING OPERATION

The 371 can directly control the temperature of up to 5 heating zones. In order to measure

the indoor temperature, each zone requires either an Indoor Sensor or a Room Tempera-

ture Unit (RTU). With an RTU the desired zone temperature is set using the RTU dial, but

with an Indoor Sensor the desired zone temperature is fixed at 72

°

F (22

°

C).

boiler

sensor

injection

pump

Maximum

Supply

Setpoint

Demand

OR

Max. Supply / Setpnt

120

170

°

F

220

boiler

sensor

M

mixing valve

70

Indoor Sensor

RTU

Off

DHW during

UnOcc.

23

DHW

Dem

DHW

Demand

4

L