Derivative (d), P + i + d = pid, Zone load coordination – tekmar 371 House Control User Manual

Page 5: Zone post purge, Unoccupied (night setback), Optimum start / stop with water temperature boost

5

In order to overcome this offset, integral control logic is used. Only digital controls can provide integral control logic due to the lengthy

response time of buildings. Integral control logic is based on time. The longer the room temperature is below the desired setpoint,

the more heat is supplied to the room. With integral control logic, full heat can be supplied to the room on the coldest day of the

year without requiring that the room be cold.

Derivative (D)

In order to speed up the control’s response to quick changes in the heating load, derivative control logic is required. However,

sudden room temperature changes, for example from an open door or window, should be ignored by an intelligent control.

P + I + D = PID

If proportional, integral and derivative (PID) control logic are combined, the control is more able to prevent excessive temperature

swings and provide a stable room temperature under all conditions. It not only takes into account how much the room temperature

has drooped, but also how long there has been a droop and how fast the temperature is changing.

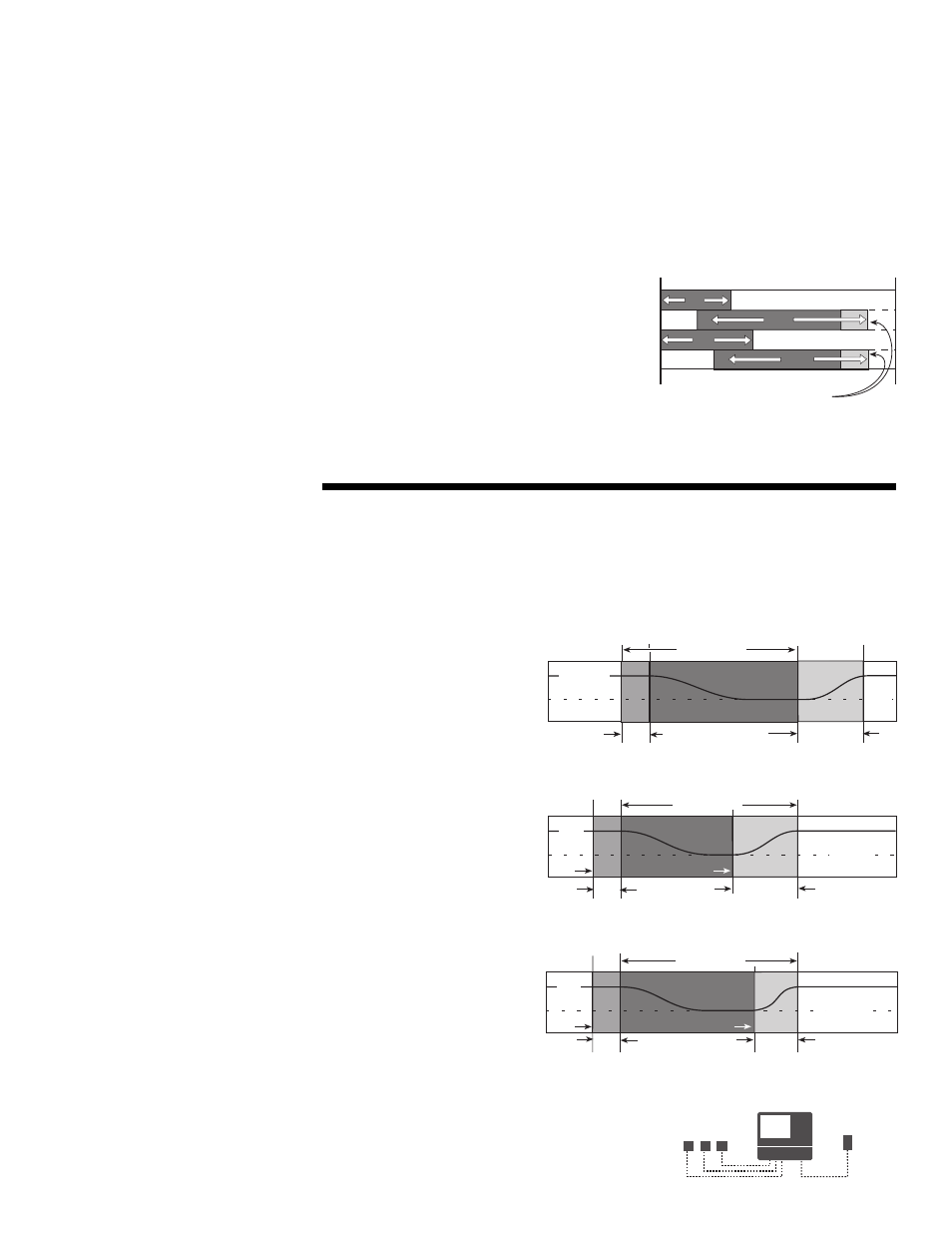

Zone Load Coordination

In a multiple zone system, there can be sudden load changes on the boiler and system

due to multiple zones turning on or off. These sudden load changes often lead to boiler

short cycling and unnecessary mechanical stresses. The operation of the system can be

improved by staggering the starting points of each zone relay within the operating cycle.

Staggering of the zones maintains a relatively constant system flow rate which improves

boiler operation. Controlled staggering can also minimize boiler running time and improve

system efficiency when only a few zones are needed for short periods.

Zone Post Purge

Before the last zone is turned off in a heating cycle, the boiler is turned off but the zone continues to draw heat from the boiler. This

post purge of the boiler reduces stand-by losses and reduces overall energy consumption.

UNOCCUPIED (NIGHT SETBACK)

During the night, or at times when people are not within the building, energy can be saved by lowering the building temperature for an

UnOccupied (Night Setback) period.

Due to the large thermal mass of buildings, it takes a long time for the indoor space temperature to significantly change whenever the

heating system is turned on or off. The building heat up or cool down time is further increased when high mass heating systems are

used (e.g. radiant floors). In most cases night setback cannot be used with these systems due to the long recovery time required in the

morning. A typical system is demonstrated in the adjacent diagram.

At the start of the night setback period the heat is turned off, but the heat

contained within the slab or radiator continues to heat the building and

there is a delay before the space temperature begins to drop. At the end

of this delay the temperature within the building gradually decreases, and

may eventually reach the required UnOccupied temperature after suffi-

cient time has elapsed. Once the setback period is complete, the heat is

turned on again but there is a long recovery time required to raise the

space temperature to the desired setpoint. The length of the delay and

recovery periods changes with outdoor temperature and is different for

each zone within the building.

A comfortable setback can be provided if the control “learns” the

response time for each zone within the building. Based on the zone’s

response time, the control can then calculate an Optimum Stop time and

an Optimum Start time. At the Optimum Stop time the control turns off the

zone valve or pump before the selected UnOcc time in order to overcome

the delay period. At the Optimum Start time, the control starts to raise the

zone temperature before the selected Occ time in order to overcome the

recovery period. This allows night setback to be used with most

heating systems.

Optimum Start / Stop with Water Temperature Boost

When Optimum Start / Stop is combined with Outdoor Reset, the

control can boost the water temperature during the recovery period.

This provides a faster recovery and allows a longer setback for greater

energy savings.

The accuracy of the Optimum Start / Stop routine depends on the

feedback available to the control.

Optimum Start / Stop with both Outdoor and Indoor Sensors

The response time of the building varies with outdoor temperature and is also different

for each zone. The most accurate Optimum Start / Stop routine is therefore achieved

when both the indoor and outdoor temperatures are monitored during transitions between

UnOccupied and Occupied modes.

Zone 1

Zone 2

Zone 3

Zone 4

Post Purge

(Boiler off, Pump on)

On

On

On

On

On

Delay

Period

8 A.M.

10 P.M. 11 P.M.

11 A.M.

Recovery

Period

Setback Period

Occ

70

°

F (21

°

C)

UnOcc

65

°

F

(18

°

C)

Delay

Period

5 A.M.

9 P.M.

10 P.M.

8 A.M.

Room Temperature

Setback Period

Optimum

Stop

Recovery

Period

Optimum

Start

Occ

70

°

F

(21

°

C)

UnOcc

65

°

F (18

°

C)

Delay

Period

6 A.M.

9 P.M.

10 P.M.

8 A.M.

Room Temperature

Setback Period

Optimum

Stop

Shorter

Recovery

Period

Optimum

Start

UnOcc

65

°

F (18

°

C)

Occ

70

°

F

(21

°

C)

Room

Temperature

Units (RTU's)

Outdoor

Sensor