Testing the control – tekmar 371 House Control User Manual

Page 16

16

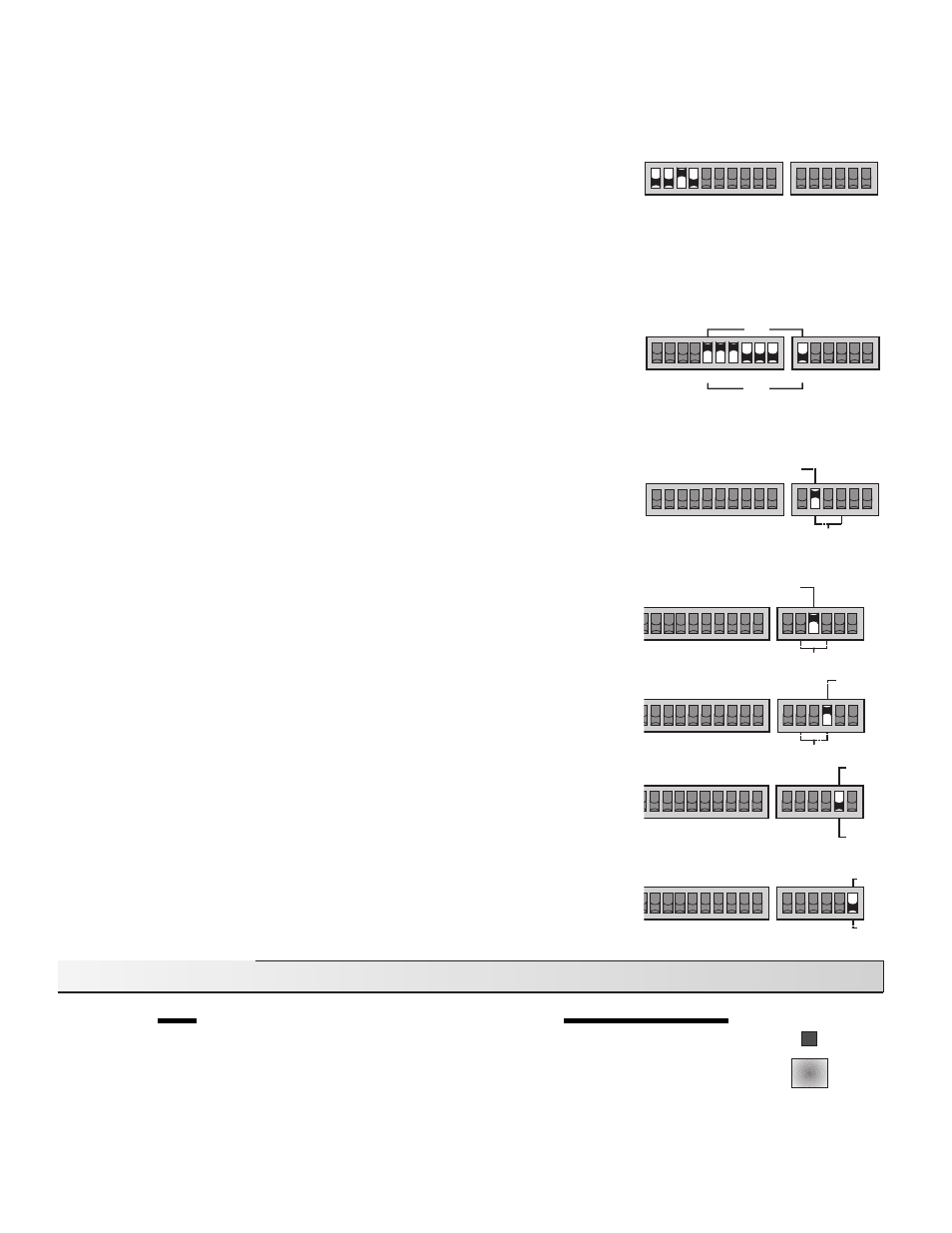

DIP Switch Settings

Note Once the control is in operation, the control will not update any changes in the

DIP switches until the next heating or cooling cycle.

Occ / UnOcc — Occ. Only

Each zone can be selected to operate in either Occupied only mode or in both Occupied

and UnOccupied modes. If the DIP switch is set to

1,2 Occ. only, the zones connected

to relays

1 and 2 remain in the Occupied mode at all times. If the DIP switch is set to

1,2 Occ / UnOcc, zones 1 and 2 are switched into UnOccupied mode each time the 371

receives an UnOccupied signal. Zones

3, 4, and 5 can be individually selected for

Occupied only or both UnOccupied and Occupied mode operation.

Mixing — Boiler

Each zone can be individually selected to operate either in the

Boiler mode or Mixing

Mode. If a zone's DIP switch is set to

Mixing, the 371 assumes this zone is in the mixing

(warm water) loop, and if the zone's DIP switch is set to

Boiler, the 371 assumes the

zone is in the boiler (hot water) loop.

If a zone control is connected with the 371 and it is used to control boiler (hot water)

zones the

Zo DIP switch must be set to Boiler. If the zone control is operating mixing

(warm water) zones, the

Zo DIP switch must be set to Mixing.

If a setpoint demand is used to control a boiler (hot water) load, the

Setpnt DIP switch

must be set to

Boiler. If the setpoint demand controls a mixing (warm water) load the

Setpnt DIP switch must be set to Mixing.

Optimum Start

The Optimum Start / Stop feature is used during transitions between the UnOccupied

mode (Night Setback) and the Occupied mode. When the DIP switch is set to

Optimum

Start, the 371 raises the building temperature during the final stages of the UnOccupied

period. This helps ensure the building is at the Occupied temperature as soon as the

Occupied period begins. If the Optimum Start DIP switch is set to

Off, the 371 does not

start raising the building temperature until the UnOccupied period ends. More informa-

tion on the Optimum Start feature is provided on page 5 of this brochure.

Thermal Motor

Zone valves with thermal actuating motors have long opening and closing times. In

order for the 371 to compensate for these longer times, the DIP switch should be set

to

Thermal Motor. If fast acting electric motor zone valves or zone pumps are used, the

DIP switch must be set to

Off.

DHW during UnOcc.

If the DHW tank requires heating during the UnOccupied mode, the DIP switch should

be set to

DHW during UnOcc.. When this DIP switch is set to Off, the 371 ignores all

DHW demands during the UnOccupied period.

Floating / Var. Speed

The 371 can provide mixing reset by operating a variable speed injection pump or by

modulating a mixing valve. If variable speed injection pumping is used , the DIP switch

must be set to

Var. Speed. If a mixing valve actuator is connected to terminals

Opn 4 — Cls 5 (30 and 31), the DIP switch must be set to Floating.

Zone 1 Cool / Zone 1 Heat

The zone

1 relay can be used to control a heating zone or to operate a cooling system.

If zone

1 is to be used for a heating zone, the DIP switch must be set to Zone 1 Heat.

If zone

1 is used for cooling, the DIP switch must be set to Zone 1 Cool.

Testing the Control

STEP SEVEN

OPERATIONAL TEST OF CONTROL FUNCTIONS

The House Control 371 has a test routine which is used to test the main control functions. The 371 continually

checks the sensors and displays an error message whenever a fault is found. See page 19 for the list of error

messages. When the

Test button is pushed, the Test light is turned on. The WWSD, Maximum Supply,

Minimum Boiler and Optimum Start / Stop lights are turned off and the individual outputs and relays are tested

in the following test sequence.

Test Sequence

Each step in the test sequence lasts 10 seconds. At the end of each step, the device continues to operate until it is turned off in a

later step.

Occ/UnOcc

Permitted

1,2

4

3

Occ. only

5

Setpnt

Boiler

1 2 3 4 5 Zo

Mixing

Zone 1 Heat

Zone 1 Cool

Floating

Var. Speed

Off

DHW during UnOcc.

Off

Thermal Motor

Off

Optimum Start

Test