tekmar 371 House Control User Manual

Page 13

13

STEP FIVE

TESTING THE WIRING

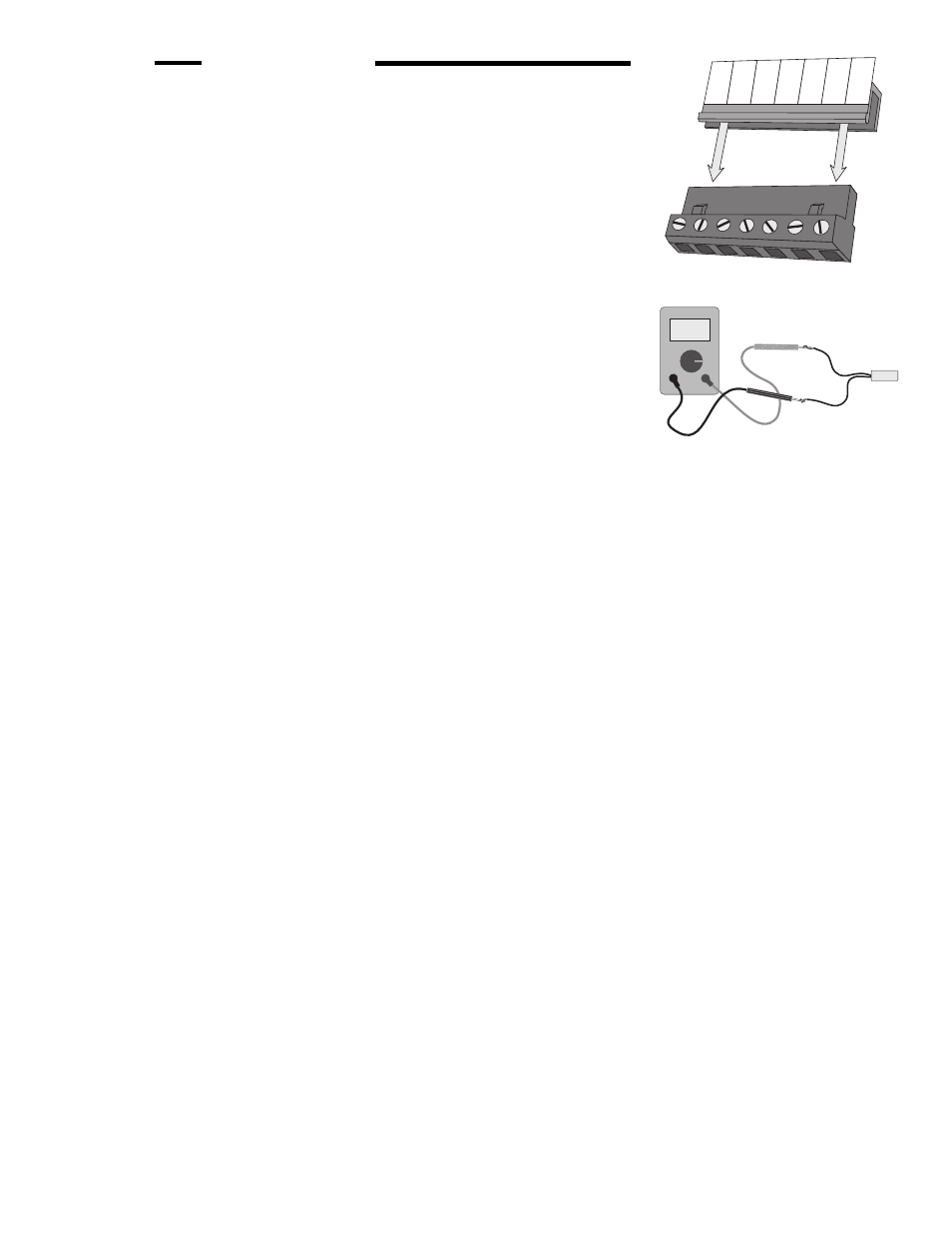

Each terminal block must be unplugged from its header on the control before power

is applied for testing. Pull straight down to unplug the terminal block.

The following tests are to be performed using standard testing practices and procedures

and should only be carried out by properly trained and experienced persons.

A good quality electrical test meter, capable of reading from at least 0 — 300 V (ac) and at

least 0 — 2,000,000 Ohms, is essential to properly test the wiring and sensors.

Test the Sensors

In order to test the sensors and Room Temperature Units (RTUs), the actual temperature

at each sensor and RTU location must be measured. A good quality digital thermometer

with a surface temperature probe is recommended for ease of use and accuracy of

testing. Where a digital thermometer is not available, a spare sensor can be strapped

alongside the one to be tested and the readings compared. Test the sensors and RTU(s)

according to the instructions in the Data Brochures D 074 and D 054.

Test the Power Supply

Make sure exposed wires or bare terminals are not in contact with other wires or grounded

surfaces. Turn on the power and measure the voltage between the

Power N — L (3 and 4)

terminals using an AC voltmeter, the reading should be between 110 and 130 V (ac).

Test the Powered Inputs

DHW Demand

If a DHW Demand is used, measure the voltage between the

Power N (3) and DHW Dem (23) terminals. When the DHW Demand

device (aquastat etc.) calls for heat, you should measure between 110 and 130 V (ac) at the terminals. When the DHW Demand

device is off, you should measure less than 5 V (ac).

Setpoint Demand

If a Setpoint demand is used, measure the voltage between the

Power N (3) and Setp Dem (24) terminals. When the Setpoint

Demand device (aquastat, etc.) calls for heat, you should measure between 110 and 130 V (ac) at the terminals. When the Setpoint

Demand device is off, you should measure less than 5 V (ac).

Test the Outputs

Boiler System Pump (P1)

If a boiler system pump is connected to the

Sys P1 (2) terminal, make sure power to the terminal block is off and install a jumper

between the terminals

Sys P1 — Power L (2 and 4). When power is applied to the terminals Power N — L (3 and 4), the boiler system

pump should start. If the pump does not turn on, check the wiring between the terminal block and the pump and refer to any

installation or troubleshooting information supplied with the pump. If the pump operates properly, disconnect the power and remove

the jumper.

Mixing System Pump (P2)

If a mixing system pump is connected to the

Sys P2 (1) terminal, make sure power to the terminal block is off and install a jumper

between the terminals

Sys P2 — Power L (1 and 4). When power is applied to the terminals Power N — L (3 and 4), the mixing

system pump (P2) should start. If the pump does not turn on, check the wiring between the terminal block and the pump and refer

to any installation or troubleshooting information supplied with the pump. If the pump operates properly, disconnect the power and

remove the jumper.

Variable Speed Injection Pump

If a variable speed injection pump is connected to the terminal

Var. Pmp (5), make sure power to the terminal block is off and install

a jumper between the terminals

Power L — Var . Pmp (4 and 5). When power is applied to terminals Power N — L (3 and 4), the

variable speed injection pump should operate at full speed. If the pump does not operate, check the wiring between the terminal

block and the pump and refer to any installation or troubleshooting information supplied with the pump. If the pump operates

properly, disconnect the power and remove the jumper.

Mixing Valve Actuator

If a floating action actuating motor is connected to terminals

Com 3-5 — Opn 4 — Cls 5 (28, 30 and 31), make sure power to the

motor circuit is off and install a jumper between terminals Com 3-5 —

Opn 4 (28 and 30). When the circuit is powered up, the valve

should start to open. If it does not, check the wiring between the terminal and the actuating motor and refer to any installation or

troubleshooting information supplied with the motor. If the valve closes instead of opening, the wiring to the actuating motor must

be reversed. If the valve opens correctly, turn off the power to the circuit and remove the jumper. Install a jumper between the

terminals

Com 3-5 — Cls 5 (28 and 31). When the circuit is powered up, the valve should start to close. If it does not, check the

wiring between the terminal and the actuating motor and refer to any installation or troubleshooting information supplied with the

motor. If the valve closes correctly, turn off the power to the circuit and remove the jumper.

13 14 15

17

16

18 19

Boil

Sen

Zo

In

Out

Sen

Com

Sen

Sup

Sen

UnO

Sw

Com

Sen

Ω

Ω