Installation cont – Powers PB410 Series Pressure Balancing Mixing Valves - Pressure Balancing Mixing Valve User Manual

Page 3

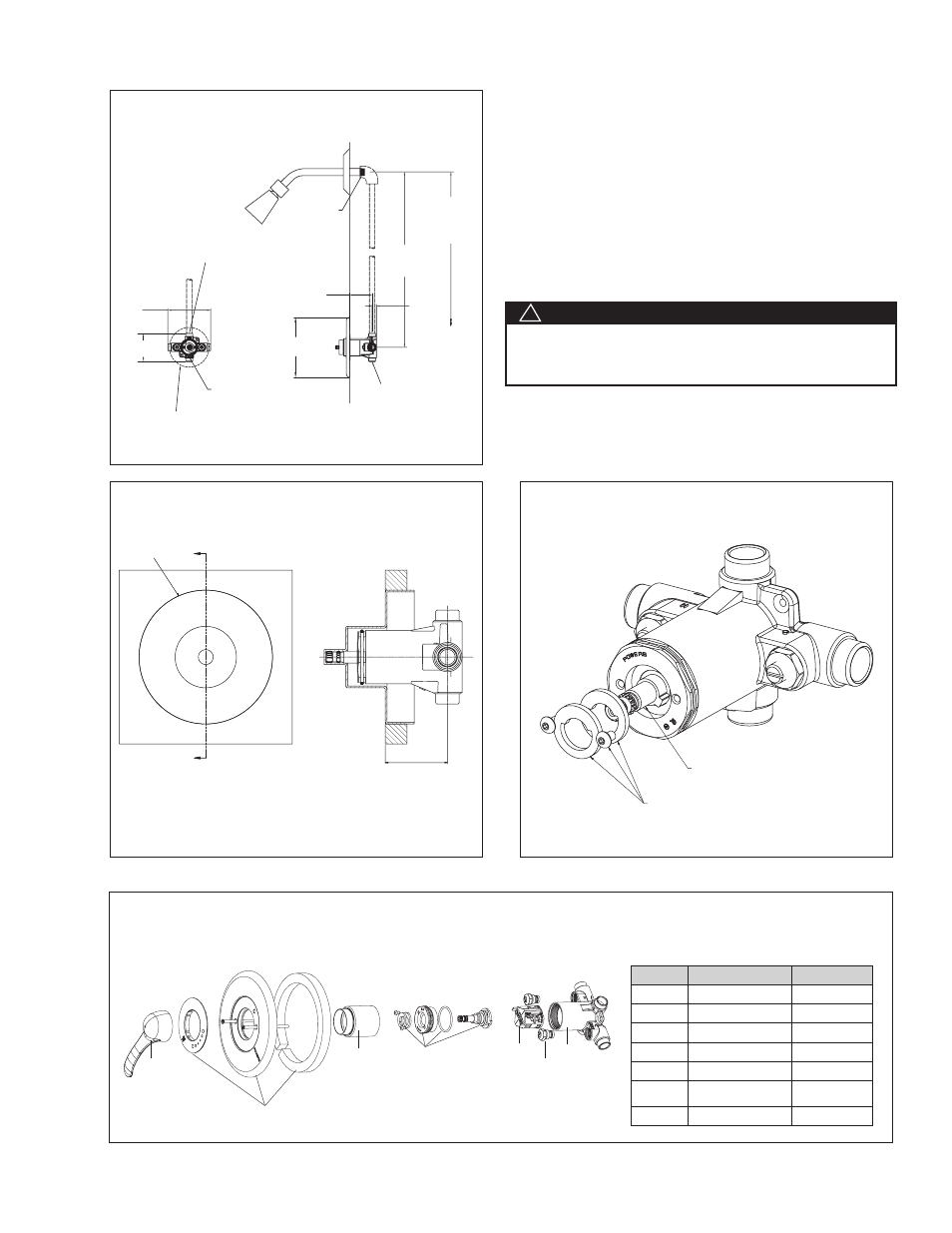

Installation Cont.

n

Item No.

Description

Kit No.

1

Handle Kit

420 049

2

Trim Plate Kit

410 022

3

Sleeve Kit

220 054

4

Bonnet/Stem Kit

410 410

5

Cartridge

900 240

6

Check stop

Replacement Kit

900 050

7

Body

N/A

3

78" (1981mm)

Approx. to

Finished Floor

1

⁄

2

"

(13mm)

24" (609mm)

Approx.

Tub outlet TP be plugged.

Plug by others.

7" (178mm)

2

7

⁄

16

" (62mm) MAX.

1

7

⁄

16

" (37mm) MIN.

1

⁄

2

" - 14 NPT

Male Inlet

'Tub' to be on

the bottom

1

⁄

2

" IPS Connections or

1

⁄

2

" Copper Sweat

Connection

5"

(127mm)

3

1

⁄

4

" (83mm)

4

5

⁄

8

"

(117mm)

Rough - In Guide

Exploded view chart.

Figure 6

Figure 4

Figure 5

MIN - MAX

1

7

⁄

16

- 2

7

⁄

16

(37 - 62mm)

G

G

4

5

⁄

8

(117cm)

High Temp

Limit Stop

Stem

12. The high-temperature limit stop is located at the center of

the bonnet. To adjust the temperature, unscrew two bon-

net screws halfway. To increase the temperature, rotate

the stem counter-clockwise to the required temperature

using the handle for leverage. Do not place pliers or chan-

nel locks on the spline of the stem. Tighten the two bonnet

screws. To decrease temperature, turn the stem clockwise

to the required temperature. Rotate the limit stop with the

help of small flathead screwdriver clockwise until it touch-

es the stem stop. Tighten the two bonnet screws. Close

valve and open it to verify setting (See Figure 5).

1

3

4

5

7

6

Figure 3 - Rough-in Dimensions - Shower ONLY

Always verify the maximum temperature setting of the valve

when any changes are made. This should also be checked

as a part of a facilities maintenance/safety program.

WARNING

!