Powers MM430 2 Valve HiLo User Manual

Page 2

Set Up Procedure

n

You must follow these procedures in order to properly adjust your Hi/

Lo System. You need flow greater than the minimum shown in capac-

ity table across the valve in order to set a maximum temperature.

1. Close the low flow valve on the outlet of the low flow valve.

2. Open the ball valve at the discharge of the high flow valve.

3. Open enough fixtures to meet the minimum flow requirement as

per capacity table.

4. Set valve temperature. Refer to IS-P-LFMM430.

5. Set the PRV as follows for a 15psi differential.

a) Loosen the locknut at the top of the PRV. This must be all the

way out or you will be limiting the range of the adjustment. b)

Adjust the PRV so the outlet pressure gauge (top) reads 15psi

less than the supply pressure gauge (bottom). Turning the

adjustment screw counterclockwise will increase the differential

across the PRV (allowing the PRV to open later).

6. Close the ball valve at the discharge of the high flow valve and

open the low flow side ball valve by rotating the handle fully

counterclockwise.

7. Open enough fixtures to meet the minimum flow requirement as

per capacity table.

8. Set the temperature for the low flow valve. Refer to

IS-P-LFLM490-LFLM490-10.

9. Open the ball valve at the discharge of high flow valve.

10. Open additional fixtures to create a 20psi differential between

supply and outlet pressure gauges.

11. When water is at desired outlet temperature, verify temperature

remains at set point.

2

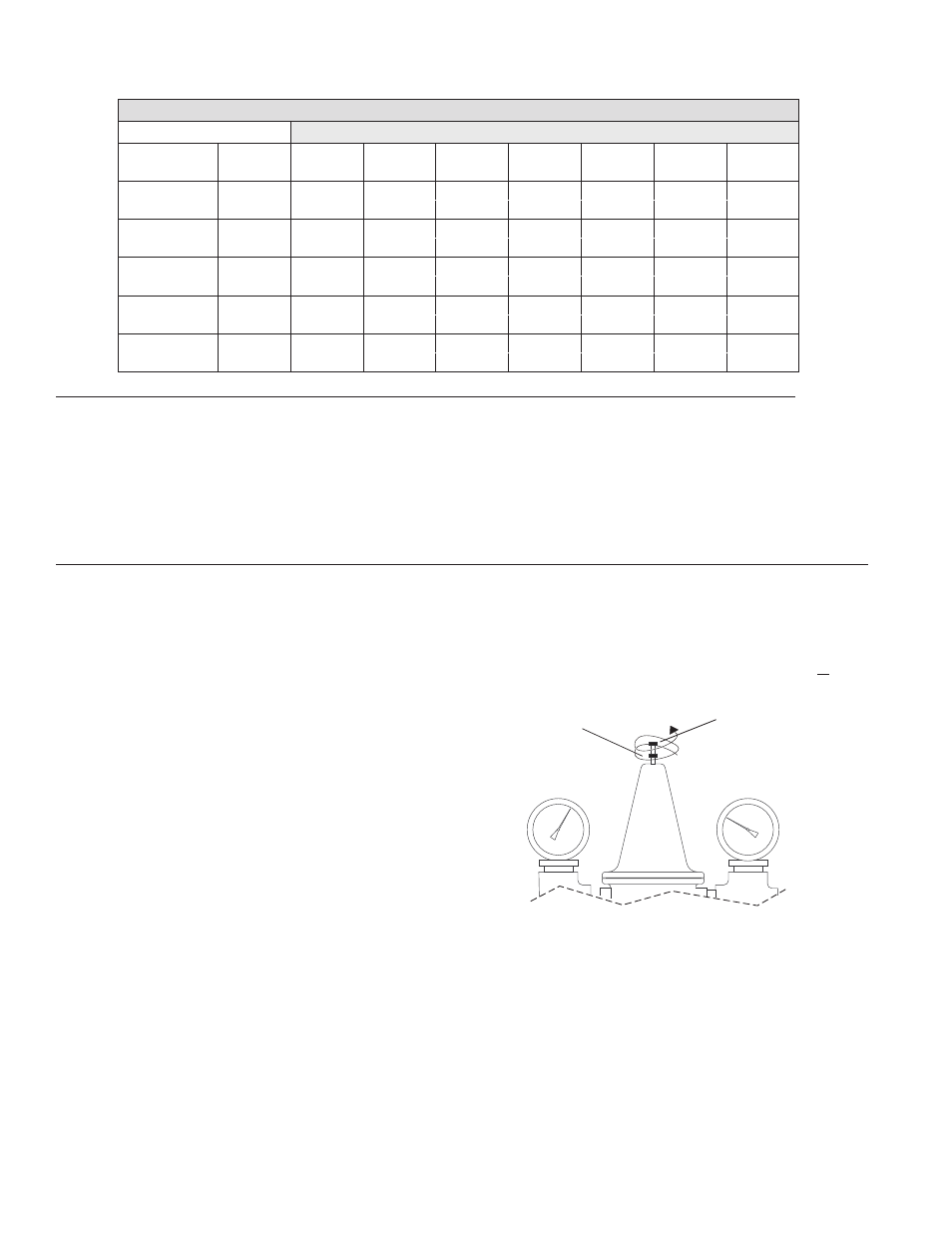

Supply Pressure Gauge

Outlet Pressure Gauge

Lock Nut

Turn fully CCW

(counterclockwise)

before setting PRV.

Adjustment Screw

CW: Increases outlet pressure and

decreases differential across PRV or

CCW: Decreases outlet pressure and

increases differential across PRV.

Capacity

n

Flow Capacity at 50-50 Mixed Ratio

P r e s s u r e D r o p A c r o s s V a l v e

Model

Min. Flow

C

V

5psi

10psi

20psi

30psi

45psi

60psi

to ASSE 1017

(34 kPa)

(69 kPa)

(138 kPa)

(207 kPa)

(310 kPa)

(414 kPa)

LFMM431HL

0.5 gpm

9.7

22 gpm

31 gpm

43 gpm

53 gpm

65 gpm

75 gpm

1.89 lpm

83 lpm

117 lpm

163 lpm

201 lpm

246 lpm

284 lpm

LFMM432HL

0.5 gpm

13.0

29 gpm

41 gpm

58 gpm

66 gpm

87 gpm

93 gpm

1.89 lpm

110 lpm

155 lpm

220 lpm

250 lpm

329 lpm

352 lpm

LFMM433HL

0.5 gpm

19.8

44 gpm

63 gpm

86 gpm

108 gpm

133 gpm

153 gpm

1.89 lpm

167 lpm

238 lpm

326 lpm

409 lpm

503 lpm

579 lpm

LFMM434HL

0.5 gpm

24.9

56 gpm

79 gpm

111 gpm

136 gpm

167 gpm

193 gpm

1.89 lpm

212 lpm

299 lpm

420 lpm

515 lpm

632 lpm

731 lpm

LFMM435HL

3.0 gpm

27.7

62 gpm

88 gpm

124 gpm

152 gpm

186 gpm

215 gpm

11.0 lpm

235 lpm

333 lpm

469 lpm

575 lpm

704 lpm

814 lpm

12. Gradually start to close fixtures to verify that the temperature

remains constant through the full range of flow.

13. For any problem, refer to Troubleshooting section of the docu-

ment or contact Powers' Technical Support Department at

1.800.669.5430 or [email protected].

1. Flush all piping thoroughly before installing.

2. Make sure all ball valve handles are in "OFF" position.

3. In order to make any temperature adjustment to the valves,

you must open end-of-line fixtures to ensure you have ade-

quate flow across the valve.

Prior to Installation

n

4. Use a thermometer at the showerhead or install an in-line

thermometer at the point-of-use.