Warning, Repair kit, Troubleshooting – Powers LM495 Series Thermostatic Tempering Valves for Individual Lavatory Installations - PEX User Manual

Page 3

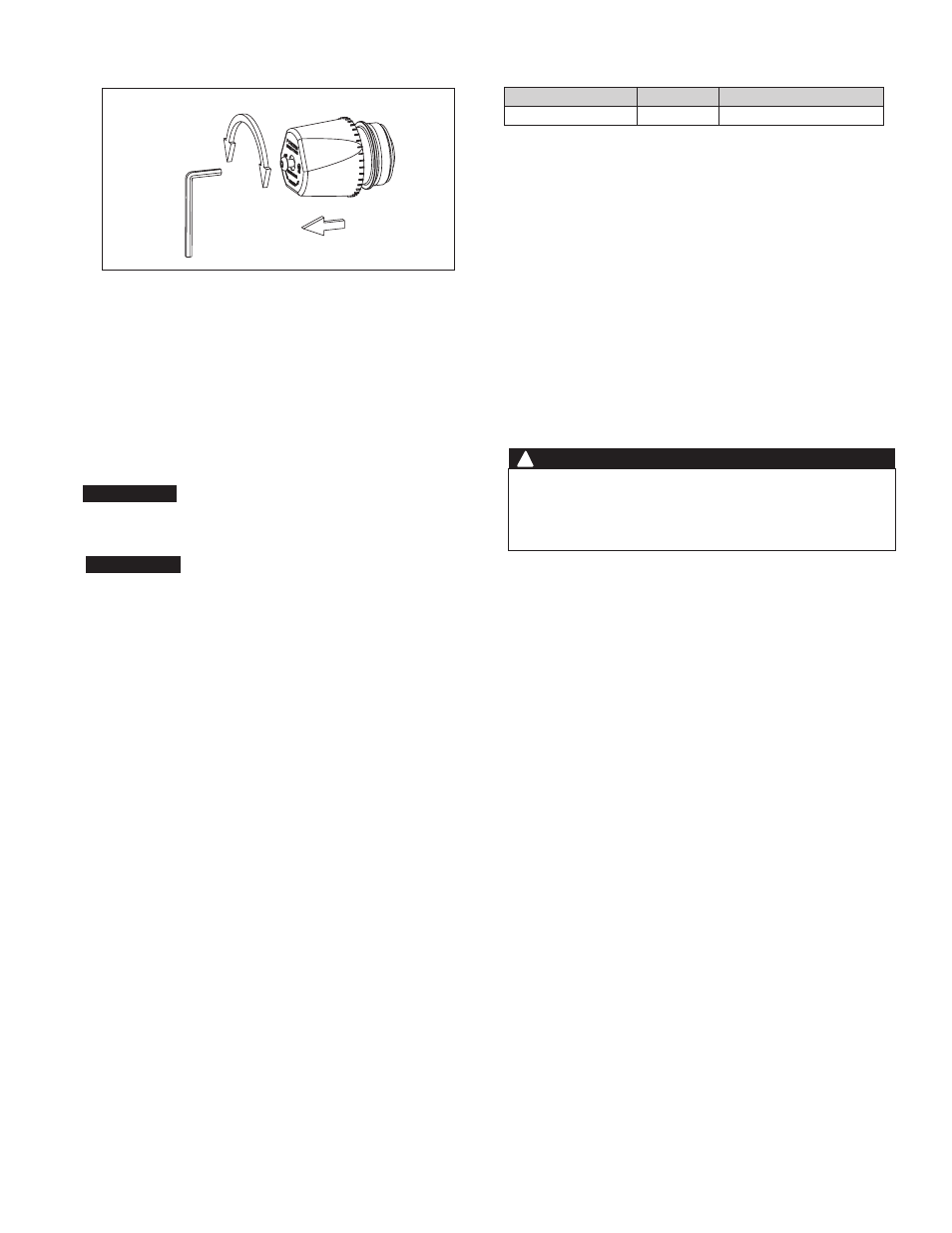

Turn

Hotter

Hex Wrench

Colder

Unscrew, Lift Cap

to Adjust

Figure 3.

1. Let the water flow for at least two minutes to allow supply tem-

perature to stabilize.

2. Place a thermometer in the outlet water stream.

3. Loosen handle screw with hex wrench.

4. Handle must be lifted

1

⁄

4

” to adjust temperature. Rotate handle

clockwise to decrease temperature and counter-clockwise to

increase the temperature.

5. Lower handle and tighten screw.

6. Check for outlet temperature.

NOTICE

Pressure Differential between Hot & Cold Water Supplies must be

less then 25%.

NOTICE

It is recommended that shutoff valve(s) be installed on the inlet(s) to

facilitate service of the LFLM495 valve.

Model

Part #

Description

LFLM495

495 100

Plunger/Motor Assembly

WARNING

!

For valves with CPVC or PEX end connections, do not exceed

the tubing manufacturers pressure and temperature ratings.

Refer to the tubing manufacturers product specifications for that

information.

Repair Kit

n

Troubleshooting

n

Fluctuating or erratic hot water temperature at fixture:

Unbalanced pressure. Install balancing or throttling valve at the

hot and cold water supplies and adjust accordingly for demand.

Hot water backing up into cold water line:

Hot water pressure is higher than cold water pressure.

Examine check valves for dirt & debris, clean as necessary.

Cannot adjust water temperature to desired temperature:

Install balancing or throttling valve at the hot and cold water sup-

plies and adjust accordingly for demand.

High pressure drop through the tempering valve:

Valve undersized. Install larger thermostatic tempering valve.

Insufficient hot water during peak demand:

Check flow requirement during peak demand period. Use larger

thermostatic tempering valve.

To Adjust Temperature (Figure 3)

n