Troubleshooting, Repair kit, Warranty – Powers LM490/LM490-10 Series Thermostatic Tempering Valves for Hot Water Heater & Multiple Lavatory Installations User Manual

Page 2: Installation instructions

LFLM490 is factory pre-set to 120°F (49°C) and LFLM490-10 is

factory set to 90°F (31°C) outlet temperatures under the following

conditions:

Cold inlet: 60° - 70°F (16 - 21°C)

Hot inlet: 140° - 145°F (60 -

63°C) Supply Pressures: 45psi

(310 kPa)

1. Let the water flow for at least

two minutes to allow supply

temperature to stabilize.

2. Place a thermometer in the

outlet water stream.

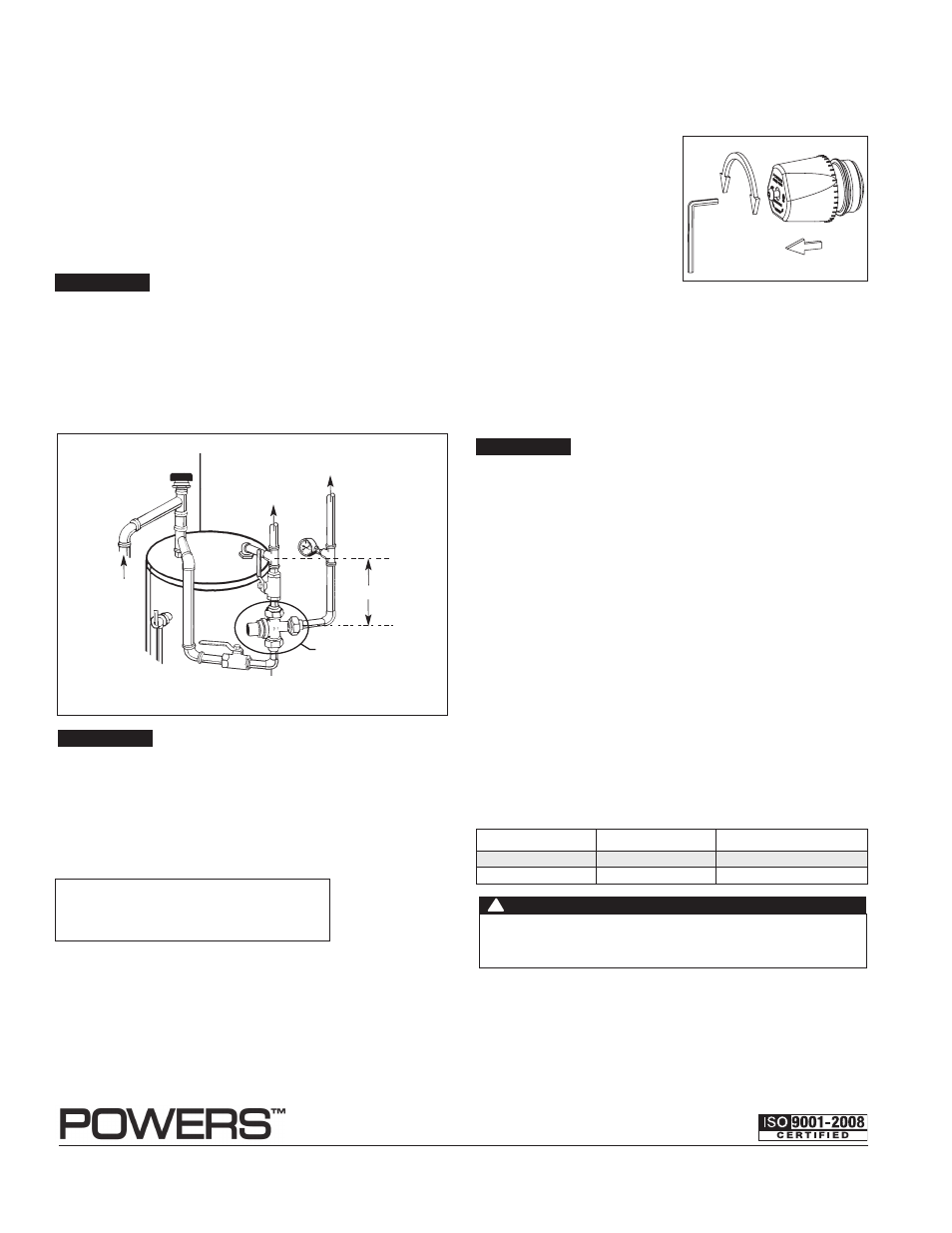

3. Loosen handle screw with hex

wrench.

4. Handle must be lifted 1/4" to adjust temperature. Rotate

handle clockwise to decrease temperature and counter-

clockwise to increase the temperature.

5. Lower handle and tighten screw.

6. Check for outlet temperature.

NOTICE

Pressure differential between hot & cold water supplies must be

less then 25%.

Fluctuating or erratic hot water temperature at fixture:

Unbalanced Pressure. Install balancing or throttling valve at the

hot and cold water supplies and adjust accordingly for demand.

Hot water backing up into cold water line:

Hot water pressure is higher than cold water pressure.

Examine check valves for dirt & debris, clean as necessary.

Cannot adjust water temperature to desired temperature:

Install balancing or throttling valve at the hot and cold water

supplies and adjust accordingly for demand.

High pressure drop through the tempering valve:

Valve undersized. Install larger thermostatic tempering valve.

Insufficient hot water during peak demand:

Check flow requirement during peak demand period. Use larger

thermostatic tempering valve.

Troubleshooting

n

Repair Kit

n

To Adjust Temperature (Figure 2)

n

Model

Part #

Description

LFLM490

490-090

Plunger/Motor Assembly

LFLM490-10

490-190

Plunger/Motor Assembly

USA: Tel: (800) 669-5430 • Fax: (847) 229-0526 • www.powerscontrols.com

Canada: Tel: (888) 208-8927 • Fax: (888) 479-2887 • www.powerscontrols.ca

IS-P-LM490-LM490-10 1336

EDP# 6511207

© 2013 Powers

Warranty

n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

ThiS expreSS warranTy iS in lieu OF and excludeS all OTher warranTieS, guaranTeeS, Or repreSenTaTiOnS, expreSS OF implied. There are

nO implied warranTieS OF merchanTaBiliTy Or OF FiTneSS FOr a parTicular purpOSe. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

A Watts Water Technologies Company

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

V acuum Relief V alve

Temperatur

e Gauge

Cold

Cold

LFLM490, LFLM490-10

8" - 10"

T emper

ed

Hot

Hot to Appliances

T&P

Relief Valve

H

C

M

Cold

Figure 1. Domestic Hot Water Application

NOTICE

To prolong the life of the series LFLM490 or LFLM490-10 valves,

it is recommended that the hot water inlet to the valve should be

8-10”(200-305mm) below the hot water inlets.

Flush all pipes thoroughly before installation. Installation and

field adjustment are the responsibility of the installer.

1. Close both hot and cold water shutoff valves upstream of the

tempering valve.

2. Bleed pressure from the system.

3. Route copper tubing or piping to fit valve dimensions.

4. For valves with Quick-Connect tailpieces refer to "Quick-

Connect Installation" instructions.

5. Remove tailpieces from the valve and make sure union nuts

are over the tubing/piping before connecting to the tailpiece.

NOTICE

If soldering, remove unions and gaskets from valve body prior to

soldering to prevent damage to valve from excessive heat.

6. Flush piping again, install valve using filter gasket on hot and

cold water inlets and fiber gasket on mixed water outlet.

7. Turn on the cold and hot water. If a leak is observed, tighten

connections as necessary to stop leak before proceeding.

Installation Instructions

n

Turn

Hotter

Hex Wrench

Colder

Unscrew, Lift Cap

to Adjust

Figure 2.

Temperature Adjustment

For valves with CPVC or PEX end connections, do not exceed the

tubing manufacturers pressure and temperature ratings. Refer to the

tubing manufacturers product specifications for that information.

WARNING

!