Powers e700 Series Combination T/P Tempering Valves - Upgrade from Biltmore 900 User Manual

Installation instructions

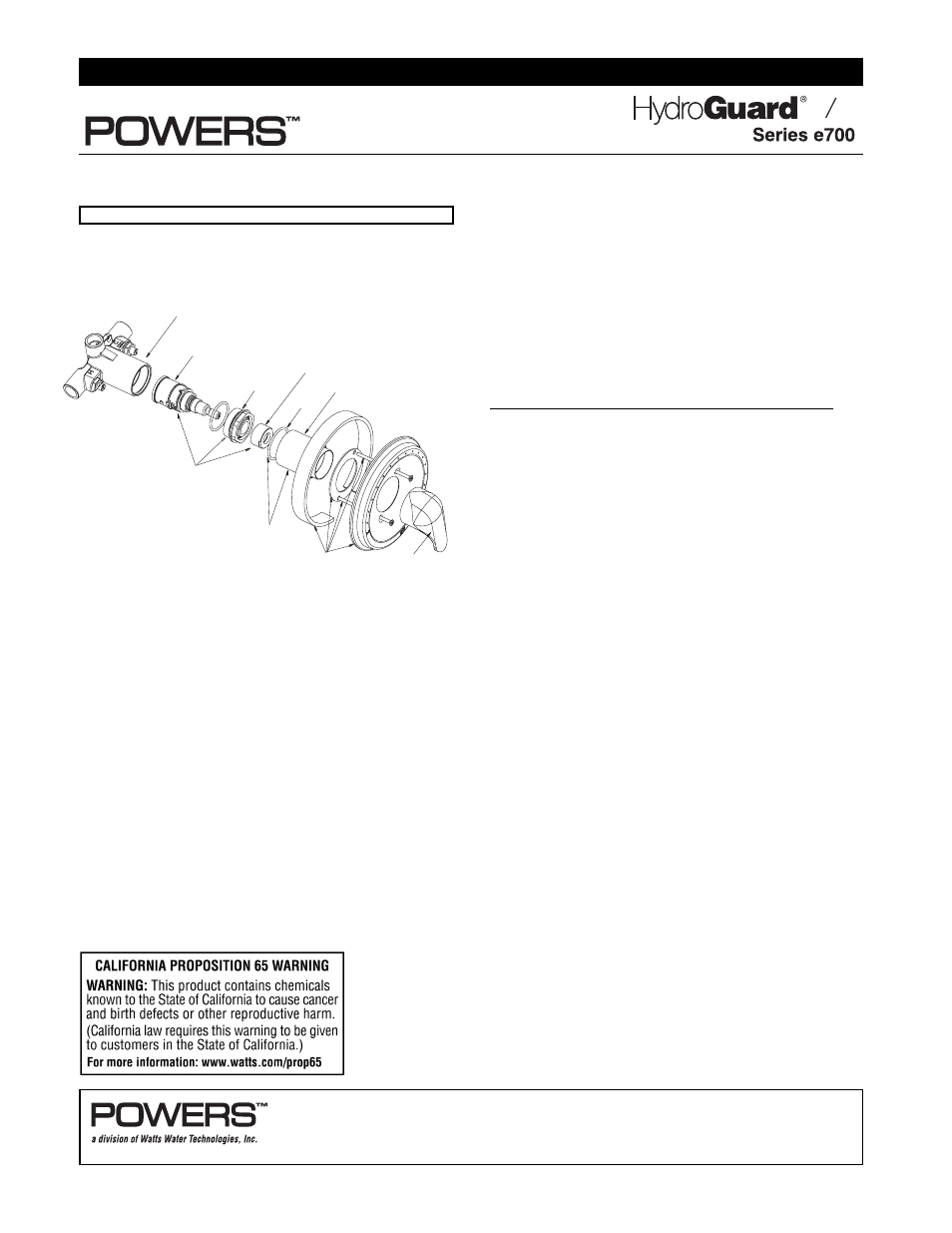

e700 RETROFIT INSTRUCTIONS

The following instructions explain how to retrofit your existing

Biltmore 900 Model 3 to an e700 which meets ASSE 1016 T/P

and CSA B125 T/P requirements. See the exploded view of

this new assembly bellow:

Before you begin your upgrade, take the time to ensure you

have all the necessary pieces. Your retrofit kit, for each valve,

consists of the following (refer to above diagram when taking

inventory):

1. Cartridge Kit

4. Handle Kit

2. Lubricant

5. Sleeve Kit

3. Trim Kit

After you verify that you have everything needed to complete

the retrofit, proceed with the next section.

Retrofit:

Follow the instructions below to perform your retrofit. Save all

components until you have successfully completed your

retrofit.

Disassembly:

1. Turn off hot & cold water supply-stops.

2. Remove the handle and trim plate.

3. Remove bonnet.

4. Remove all internal components from valve body.

5. At this point you should have an empty valve body.

You are now ready to put the new components into your

existing valve.

Reassembly:

1. Ensure the inside of the valve body is free of deposits

and debris. Clean as necessary.

2. Place the cartridge into the body ensuring following:

a) "C" on the cartridge should be on the cold inlet side.

b) Align tab on the bottom of the cartridge to the groove

in the body.

3. While holding cartridge firmly, screw bonnet into body;

tighten to 100 + 20/-0 in-lbs.

4. Turn the hot and cold water supplies back on and verify

there is no leakage.

Maximum Temperature Setting/Handle Rotation Stop

The handle rotation setting must be adjusted to limit the

distance the user can rotate the handle towards the full hot

water position.

CAUTION: Any repair or modification of the valve may affect

the high temperature setting. The maximum temperature

setting must be checked by the installer before use.

5.Adjust the valve to the desired maximum outlet tempera-

ture [110°F (43°C) max]. Screw on the high temp. limit stop

until it touches the stem shoulder.

6. Turn the stem clockwise until the water stops. Open valve

to full hot position and verify max outlet temperature setting.

6 (a) For 220 453:

1. Attach indicator plate gasket to the back of the trim

plate making sure horizontal holes on the gasket

matches horizontal holes on the trim plate. Indicator

plate locator hole matches diagonal hole on the trim

plate. Peel off backing of trim gasket and attach to the

inside top edge of the trim plate. Gasket should

approx. be 1/16" beyond the plate edge.

2. Install the trim plate with the screws provided.

3. Snap on the indicator plate. Guide on the back of the

plate goes into the locator hole.

4. Install sleeve O-ring on the bonnet. Slide sleeve on the

bonnet.

CAUTION: Indicator plate must be installed before sleeve.

5. Install handle and tighten the setscrew.

6 (b) For 220 451 & 220 452

1. Place sleeve O-ring on the bonnet shoulder. Slide

sleeve over the O-ring until it stops.

2. Install trim plate gasket.

3. Install trim plate with the screw provided.

4. Install handle and tighten set screw.

7. Your retrofit is complete!

You have just converted your type “P” valve to type “T/P”

If you have any problems, comments, or suggestions, please

contact your local Powers representative. We are interested

in feedback from the field. You can find them at www.power-

scontrols.com.

HANDLE

KIT

TRIM

KIT

CARTRIDGE

KIT

BODY

SLEEVE

KIT

CARTRIDGE

B0NNET

TEMP. LIMIT STOP

SLEEVE

"O" RING

SLEEVE

Figure 1

IIe700R 0617

EDP# 6511199

INSTALLATION INSTRUCTIONS

Complete Upgrade – Kit #220-451 & 220-452, 220-453

T P

© 2006 Powers

USA: Phone: 1.800.669.5430 • Fax 1.847. 229 . 0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1. 888. 882 .1979 • www.powerscontrols.ca

IIe700R