Powers e420 Series Combination T/P Tempering Valves - Cartridge & Trim Upgrade User Manual

Page 2

6. Place the wax element into the stem assembly, small end

first, and place this bonnet-stem-motor assembly into/onto

the valve body. Rotate the bonnet assembly to line up the

bonnet screw holes and reinstall and tighten the four

bonnet screws.

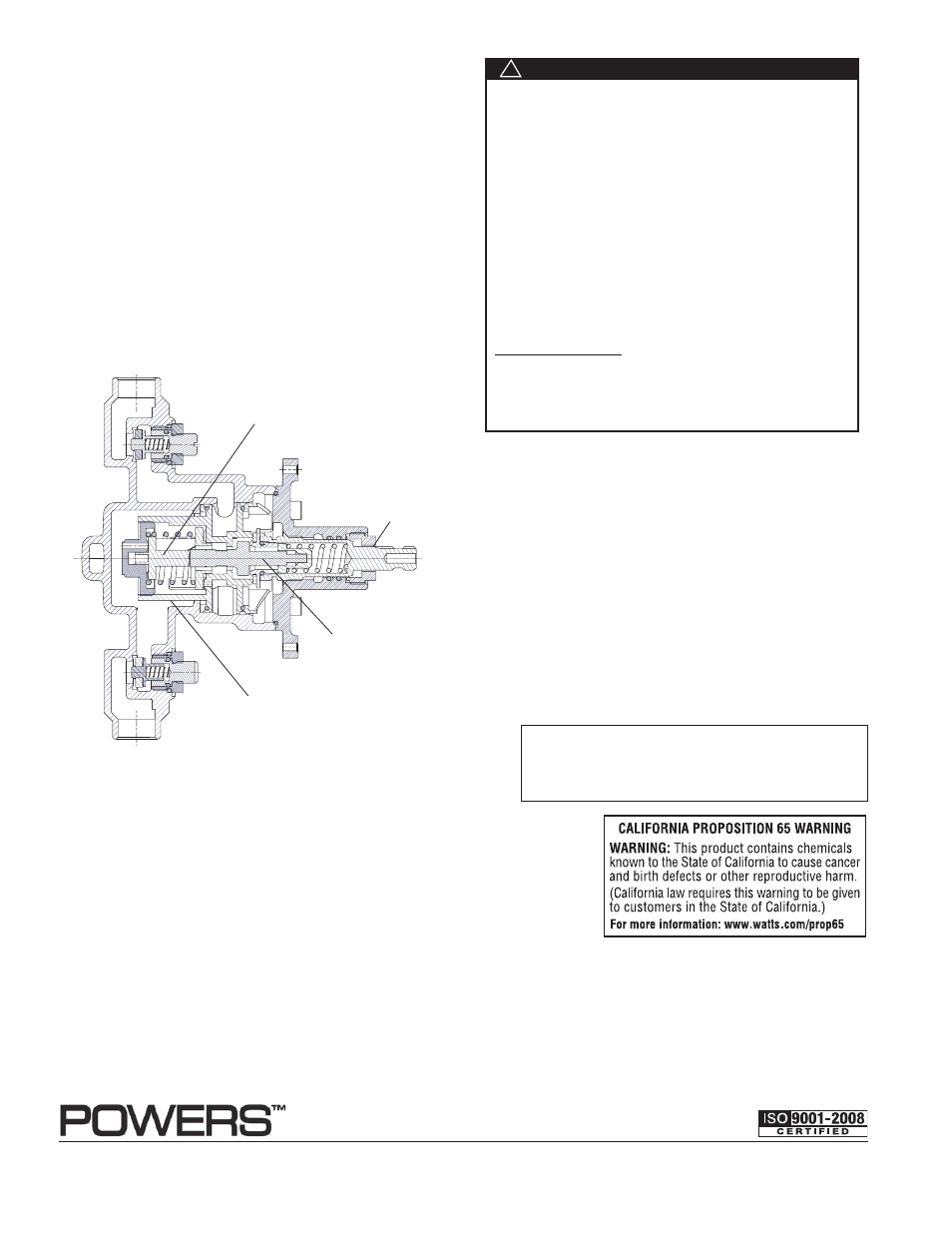

See cutaway below to see how everything goes together.

(Figure 3)

7. Rotate the stem assembly clockwise, by hand, until it

bottoms out on the cartridge. At this point your valve is

in the off position.

8. Turn the hot and cold water supplies back on and verify there

is no leakage. If the valve leaks disassemble and

go back to step #1 and reassemble.

9. Maximum Temperature Setting

Maximum temperature setting adjustment (Figure 3) must be set

on the job. The high temperature limit stop is threaded into the

bonnet and is turned counter clockwise for a decreased set-

ting. Powers recommends a maximum setting of 105°F (41°C).

To adjust temperature, rotate handle to the maximum desired

outlet temperature, screw temperature limit stop until it touches

stem’s shoulder. Close valve and open it to verify setting.

10. Your valve should now be set properly. Verify proper

operation by rotating the stem from the off position,

counterclockwise, to the high temperature position.

Verify the temperature does not exceed your desired

maximum temperature. Rotate stem back to the

off position.

11. Peel off backing of dial gasket and attach it to the inside top

edge of dial plate. Make sure gasket is approximately

1/16" beyond the plate edge.

12. Hold plate firmly against the wall. Thread sleeve on the

bonnet making sure that the cut away on the sleeve is

facing out and is in the bottom position when tightened.

Do not use any tool which will scratch the sleeve surface.

13. Install handle with the screw provided on to the stem and

tighten in place. Ensure the set screw lines up with the

groove on the adjustment stem.

Figure 3

Shuttle

Hot Water Supply

Cold Water Supply

Adjustment

Stem

Advanced Thermal

Actuator

Cartridge Assembly

Warranty

n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

ThiS expreSS warranTy iS in lieu OF and excludeS all OTher warranTieS, guaranTeeS, Or repreSenTaTiOnS, expreSS OF implied. There are

nO implied warranTieS OF merchanTaBiliTy Or OF FiTneSS FOr a parTicular purpOSe. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

USA: Phone: 1.800.669.5430 • Fax 1.847. 229.0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1.888.479.2887 • www.powerscontrols.ca

IS-P-e420R 1045

EDP#6512298

© 2010 Powers

A Watts Water Technologies Company

ATTENTION INSTALLER: After installation, please leave this

Instruction Sheet for occupant’s information.

IMPORTANT: Inquire with governing authorities for local

installation requirements.

FAILURE TO COMPLY WITH PROPER INSTALLATION

AND MAINTENANCE INSTRUCTIONS COULD

CONTRIBUTE TO THE VALVE FAILURE, RESULTING IN

INJURY. TO ENSURE THE ACCURATE AND RELIABLE

OPERATION OF THIS PRODUCT, IT IS ESSENTIAL TO:

• properly size each valve based on the individual appli-

cation.

• properly design the recirculation system to minimize

pressure and temperature variations.

• conduct an annual maintenance program to ensure

proper operation of all critical components.

• check outlet temperature to ensure it does not exceed

105°F (41°c). make sure temperature limit stop is

properly re-set to maximum 105°F (41°c) following

valve maintenance or repair. Tampering with limit

stop in any way may result in scalding temperature

causing serious bodily harm.

Periodic Inspection: Corrosive water conditions, tem-

peratures over 210°F, unauthorized adjustments or

repair could render the valve ineffective for the service

intended. Regular checking and cleaning of the valve’s

internal components helps assure maximum life and

proper product function.

WARNING

!