Installation, Operation cont – Powers e420 Series Combination T/P Tempering Valves User Manual

Page 2

Installation

n

2

78" [1981]

APPROX.

TO FINISHED

FLOOR

1 7/16" [37] MIN.

2 7/16" [62] MAX.

7/8" [23]

WALL

Ø4" [102]

1/2" NPT

MALE INLET

'S' TO BE

ON TOP

6 1/8" [155]

5 5/8" [142]

3 1/8" [79]

R1 5/8" [R40]

1/2" NPTF

CONNECTIONS

4 1/8" [105]

ALL DOTTED LINE

PIPING SUPPLIED

BY OTHERS.

78" (1981mm)

Approx.

To Finished

Floor

"S" to Be

on Top

WALL

5 1/2"

(139mm)

15/16"

(23mm)

All Dotted Line Piping

Supplied By Others

6 1/16"

(155mm)

3 1/8"(79mm)

4 1/8"(105mm) 4"(101mm)

3 1/8"(79) max

2 3/8"(60) min

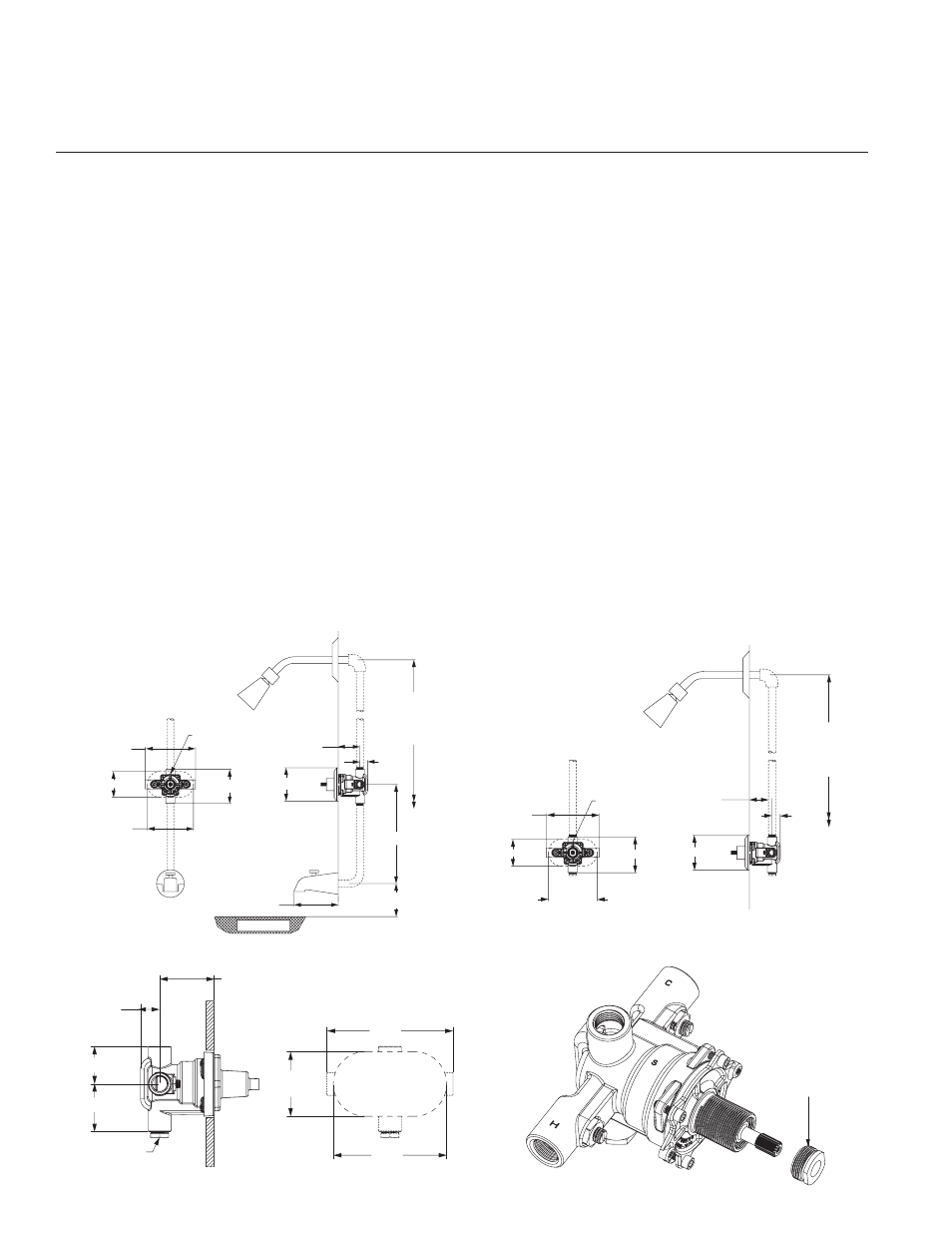

Figure 2:

Rough-in Dimensions

– Shower Only

Wall

78" (1981mm)

Approx.

To Finished

Floor

"S" to Be

on Top

6 1/16"

(155mm)

5 1/2"

(139mm)

5 3/8"(137mm)

4" (102mm) Approx

12" (305mm)

15/16"

(23mm)

Tub Rim

All Dotted Line Piping

Supplied By Others

3 1/8"(79mm)

4 1/8"(105mm)4"(101mm)

3 1/8"(79mm) max

2 3/8"(60mm) min

Figure 1:

Rough-in Dimensions

– Tub and Shower

3 1/8"(79mm) max

15/16"

(23mm)

6 1/16"

(155mm)

5 1/2"

(139mm)

3 1/8"

(79mm)

1 13/16"(46mm)

2 5/16"(58mm)

Optional For

3 Port Valve

2 3/8"(60mm) min

SIDE VIEW

FRONT VIEW

Figure 3:

Rough-in Guide

Clockwise for

cooler temperature.

Counter clockwise

for warmer temperature

Figure 4:

Max Temperature

Setting

NOTE: Installation should be in accordance with accepted plumbing

practices. Flush all piping thoroughly before installation. Failure to do

so can result in a valve malfunction.

TO INSTALL

1 . Position mixing valve 2 3/4" ±3/8" (69mm ± 10mm) from inlet center

to finished wall surface. For reference a rough-in guide is provided,

ensure it is pushed on fully and the valve is closed when positioning

valve. The tub outlet port is marked TUB” and should face down.

Facing the front of the mixing valve, connect hot water to left side

and connect cold water to right side. The mixing valve has “C” and

“H” cast into the body near the appropriate ports. Inlets and outlet

connections must be piped correctly for proper operation of valve.

If hot and cold water connections are reversed, valve will not func-

tion properly.

2. For tub and shower installations, see Figure 1. Pipe bottom outlet

port “TUB” directly to the diverter tub spout. The mixing valve is

designed to operate without the use of a twin ell. Pipe top outlet port

“S” to the showerhead.

3. For shower only installation, see Figure 2. Pipe top outlet port “S”

directly to the showerhead and plug bottom port.

CAUTION: When soldering during the installation process, do not

heat the valve any higher than the temperature required to flow solder.

Excessive overheating of the valve may cause damage to the valve

internals. By following this recommendation, you will be able to solder

the valve without removing either the cartridge or the checkstops inter-

nals. If either brazing or resistance (electric) solder is used, all check-

stop and valve internals must be removed.

4. Turn hot and cold water supplies on and verify there are no leaks.

5. Rough-in guide installation

a. Before strapping the pipes and before completing the finished

wall, slide rough-in guide onto the mixing valve stem and press

fit into place, see Figure 3. (valve stem must be rotated fully

clockwise).

b. The rough-in guide will insure the proper size opening and

location of the finish wall.

6. After finished wall is completed, remove rough-in guide to allow

installation of the trim.

7 . Peel off backing of dial gasket and attached it to the inside top edge

of dial plate. Make sure gasket is approximately 1/16" beyond the

plate edge.

8. Hold plate firmly against the wall. Thread sleeve on the bonnet mak-

ing sure that the cut away on the sleeve is towards you and is in

the bottom position when tightened. Do not use any tool to tighten

which will scratch the sleeve surface.

9. Install handle with the screw provided.

10. Maximum temperature setting adjustment (Figure 4) must be set on

the job. The high temperature limit stop is threaded into the bonnet

and is turned counter clockwise for an increased setting and clock-

wise for a decreased setting. Powers recommends a maximum

setting of 110°F (43°C). To adjust temperature, rotate handle to the

maximum desired outlet temperature, screw temperature limit stop

until it touches stem’s shoulder. Close valve and open it to verify

setting.

Operation cont.

n

to the outlet. If the hot or cold supply water temperature or pressure

changes, the thermal actuator will contract or expand. This movement

repositions the shuttle to maintain the desired temperature. With the

adjustment handle in full clockwise (OFF) position, the shutoff disc

closes the mixing chamber from the outlet.

A temperature limit stop limits the movement of the control handle. The

standard HydroGuard

®

e420 valve is factory set to deliver tempered

water up to 110°F [43°C] with equal supply pressures, with hot water

temperature 140°F [60°C], cold water temperature 60°F [15.6°C]