Warranty, Reassembly cont – Powers e420 Series Combination T/P Tempering Valves - Cartridge (420-451) User Manual

Page 2

IS-P-420R 1446

EDP# 6507690

© 2014 Powers

USA:

Tel: (800) 669-5430 • Fax: (847) 229-0526 • PowersControls.com

Canada:

Tel: (905) 332-4090 • Fax: (905) 332-7068 • PowersControls.ca

Latin America:

(52) 81-1001-8600 • Fax: (52) 81-8000-7091 • PowersControls.com

A Watts Water Technologies Company

Warranty

n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

ThiS expreSS warranTy iS in lieu OF and excludeS all OTher warranTieS, guaranTeeS, Or repreSenTaTiOnS, expreSS OF implied. There are

nO implied warranTieS OF merchanTaBiliTy Or OF FiTneSS FOr a parTicular purpOSe. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

For more information: Watts.com/prop65

perature setting. The maximum temperature setting must be

checked by the installer before use.

9. Adjust the valve to the desired maximum outlet temperature

[110°F (43°C) max]. Install the splined limit stop with its tab clock-

wise of the bonnet stop.

10. Turn the stem clockwise until the water stops. Install the sec-

ond splined limit stop with the tab counter-clockwise of the

bonnet stop.

11. Replace handle. Repeat steps 9 and 10 (see figure 4) until

desired maximum outlet temperature is reached. Remove

handle before final assembly.

Resetting of the splined stop can result in temperatures higher than

110°F [43°C].

Set valve “off” position with bare hands only! Over tightening in the

off position with pliers or a wrench can cause internal valve damage.

If low flow or no hot water, cartridge is not fully installed.

If flow does not stop, something is wrong with the installation. Turn

off both supplies, disassemble the valve, and go back to “reassem-

bly” – step #1.

12. Your valve should now be set properly. Verify proper operation

by rotating the stem from the off position, counter-clockwise, to

the high temperature position. Verify the temperature does not

exceed your desired maximum temperature. Rotate stem back

to the off position.

13. Replace trim plate and handle.

14. Your retrofit is complete!

If you have any problems, comments, or suggestions, please con-

tact your Powers representative. We are interested in feedback

from the field.

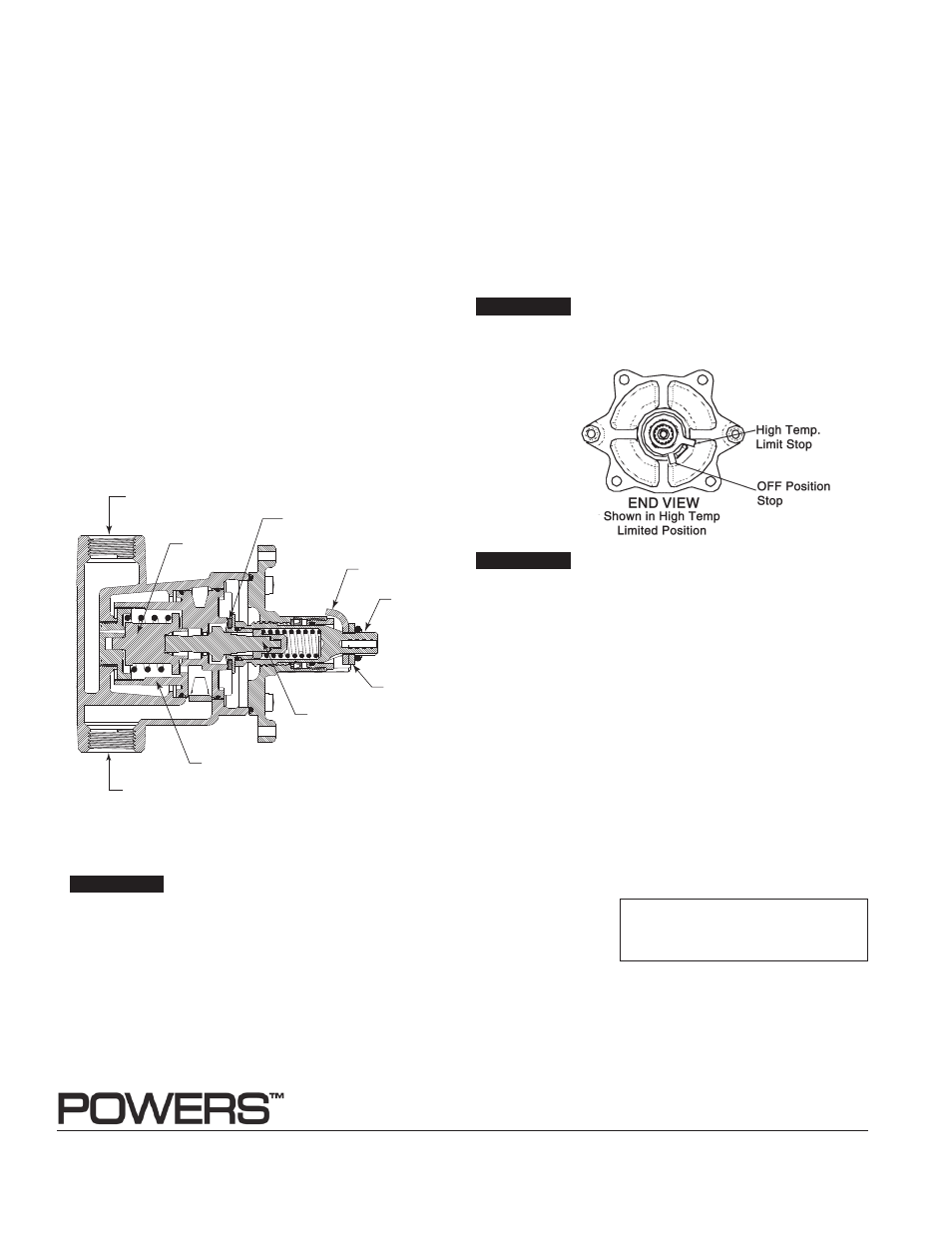

Maximum Temperature Setting/Handle Rotation Stop

The handle rotation setting must be adjusted to limit the distance

the user can rotate the handle towards the full hot water position

and the off position.

Any repair or modification of the valve may affect the high tem-

CAUTION

CAUTION

NOTICE

Hot Water Supply

Cold Water Supply

Cartridge Assembly

Advanced Thermal

Actuator

High Temp. Stop

Shut Off Disc

Shuttle

Off Position

Stop

Adjustment

Stem

Figure 3

Figure 4

fins just inside the front surface of the casting. If the cartridge

is difficult to install, or does not go in all the way, remove the

cartridge and clean the body or remove any obstructions.

Repeat this step until the cartridge installs easily.

3. Remove the cartridge and install the 2 “O” rings. Lubricate the

“O” rings with silicon lubricant.

4. Install the cartridge back into the body. The cartridge should

go in until the large fins are just inside the front surface of the

casting (same position as in step 2). If you cannot push it in all

the way due to “O”-rings, use bonnet and two (2) screws to

force in. When using bonnet screws, be sure to use a diago-

nal direction to ensure cartridge seats in the body evenly.

5. Lubricate the bonnet “O”-ring and install onto new bonnet

assembly.

6. Place the wax element into the stem assembly, small end

first, and place this bonnet-stem-motor assembly into/onto the

valve body. Rotate the bonnet assembly to line up the bonnet

screw holes and reinstall and tighten the four bonnet screws.

See cut-away below to see how everything goes together.

7. Rotate the stem assembly clock-wise, by hand, until it bottoms

out on the cartridge. At this point your valve is in the off position.

8. Turn the hot and cold water supplies back on and verify there

is no leakage.

Reassembly cont.

n