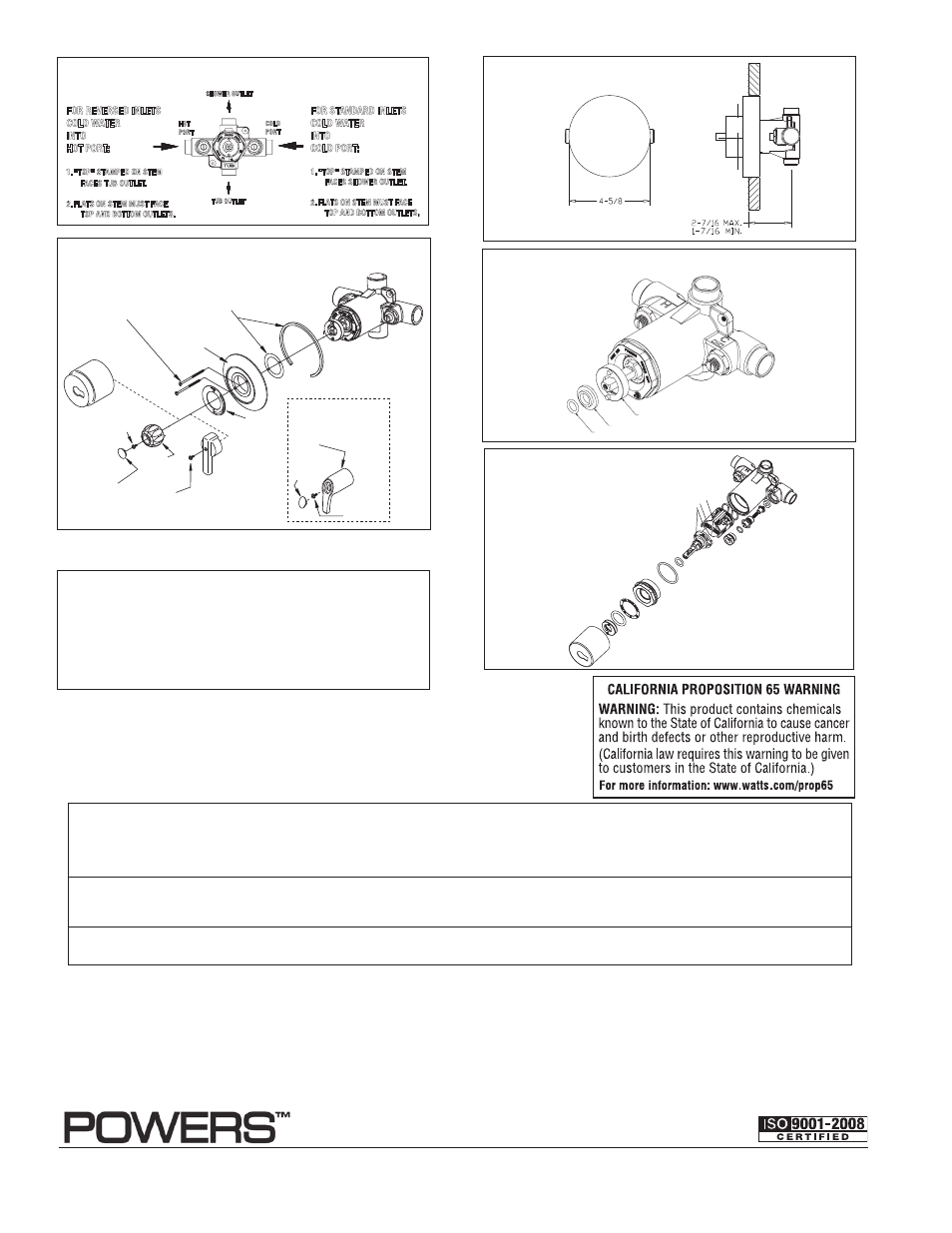

Warranty, Troubleshooting, Figure 3: stem position information power s – Powers 900 Series Biltmore Series Pressure Balancing Mixing Valves User Manual

Page 2: Figure 5

USA: Phone: 1.800.669.5430 • Fax 1.847. 229.0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1.888.479.2887 • www.powerscontrols.ca

IS-P-900 1041

EDP# 6512223

© 2010 Powers

A Watts Water Technologies Company

Warranty

n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

ThiS expreSS warranTy iS in lieu OF and excludeS all OTher warranTieS, guaranTeeS, Or repreSenTaTiOnS, expreSS OF implied. There are

nO implied warranTieS OF merchanTaBiliTy Or OF FiTneSS FOr a parTicular purpOSe. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

DESCRIPTION

TROUBLESHOOTING

REPAIR KIT NO.

gaSKeT and diSc

1) water leaks at valve stem and/or bonnet.

900 030 models 1 and 2

replacemenT

2) water leaks at valve shutoff.

3) water leaks at checkstop.

900 028 model 3

inTernalS

1) with mixer handle in mid postition, hw flows with cw.

900031a, model 1

replacemenT

checkstop closed or cw flows with hw checkstop closed. 900 031 model 2

900 032 model 3

checKSTOp

1) checkstop will not completely shut off.

900 049 models 1 and 2

replacemenT

900 050 model 3

Troubleshooting

n

HOT

PORT

COLD

PORT

SHOWER OUTLET

TUB OUTLET

FOR STANDARD INLETS

COLD WATER

INTO

COLD PORT:

1. "TOP" STAMPED ON STEM

FACES SHOWER OUTLET.

2. FLATS ON STEM MUST FACE

TOP AND BOTTOM OUTLETS.

FOR REVERSED INLETS

COLD WATER

INTO

HOT PORT:

1. "TOP" STAMPED ON STEM

FACES TUB OUTLET.

2. FLATS ON STEM MUST FACE

TOP AND BOTTOM OUTLETS.

Figure 3: Stem Position Information

POWER

S

Dial Gaskets

ABS

Dial

Plate*

Dial Plate

Screws (2)

ABS Lever Handle

Kit #900 103

Metal Lever

Handle*

900 070

ABS Lever

Handle Screw

800 164

ABS Lever

Handle Button

900 096

ABS Lever

Handle

900 091

Acrylic

Handle*

900019C

Acrylic

Handle

Button

900 140

Acrylic

Handle Screw

800 168

Metal Lever

Handle Screw

800 164

900 094

080 026

900 093

(

not used in 905 valves)

900 090

*Round Stainless Steel Dial Plate

900020A

Graphic

Insert

900 095

Sleeve*

900 132

Figure 4

NOTE: For valves sold without checkstops, it is rec-

ommended that the valve be installed where there is

shutoff upstream of the valve, so that the valve may

be easily serviced and accessed. if this is not possible,

the valve should include a shutoff or combination

checkstop/shutoff on the inlets.

Silicone

Greas

e

NOTE: SweaT inlets

shown. Threaded

inlets also available.

* Use Sleeve 900 132 in Kit 900 268 with ABS Dial.

Use Sleeve 800015H in Kit 900 269 with Round Stainless Dial.

Figure 5

High Temperature Stop

Retainer

O-ring

Figure 6: Max. Temperature Setting/Handle Rotation

Stop

REPAIR KITS: For further

information on repair and

maintenance, see TI900.