Flowrite, Control valve application data sheet, Form ads#11fw – Powers 595 Series 11 Self-Operating Temperature Regulators - Sizing Worksheet User Manual

Page 2

1.

Valve Style

R

■

■

Normally Open (air to close)

■

■

Double Acting

■

■

Normally Closed (air to open)

■

■

_________________

■

■

Mixing

2.

Valve Body Material

R

Process Connection

■

■

Bronze

■

■

Steel

■

■

Screwed

■

■

Iron

■

■

150# Flanged

■

■

Stainless

■

■

300# Flanged

■

■

______________________

3.

Capacity

E/O

Cv Rating _______________________________________________

GPM or #/hr. ____________________________________________

4.

Process Load

E/O

• Flow (GPM) of material to be

heated, cooled, or mixed ______________________________

• Temperature increase or decrease

of material ___________________________________________

5.

Flow Characteristic and Trim Material

N

■

■

Linear

■

■

Bronze

■

■

Equal %

■

■

316 SS

■

■

______________________

6.

Close Off Requirements

R

■

■

Class 2 (leakage to be 0.5% of max. flow or less) [most double seat]

■

■

Class 3 (leakage to be 0.1% of max. flow or less)

■

■

Class 4 (leakage to be .01% of max. flow or less) [most single seat]

7.

Media Through Valve

E/O

■

■

Steam

Inlet Pressure

R

________________________________________

Flowing Pressure Drop (

∆

P)

N

___________________________

■

■

Water

Inlet Pressure

R

________________________________________

Flowing Pressure Drop (

∆

P)

N

___________________________

Temperature

R

_________________________________________

■

■

Other

Material Flowing Through Valve _________________________

Inlet Pressure

R

________________________________________

Flowing Pressure Drop (

∆

P)

N

___________________________

Temperature

R

_________________________________________

7a. Close off differential _________________________________

8.

Packing Requirements

N

■

■

Service under 300°F

■

■

EP V-Ring

■

■

Service under 250°F– 400°F

■

■

Teflon V-Ring

■

■

Service 250°–500°F

■

■

Graphite

■

■

_________________

9.

Actuator Requirements

R

• Signal to Actuator

■

■

3–15 psi from I/P

■

■

1–17 psi from I/P

■

■

_______PSI from Positioning Relay

■

■

________________PSI from Pneumatic Controller

• Actuator Span

■

■

Full Range 3-15 Nominal

■

■

Split Range 3–8 psi

■

■

Split Range 10–15 psi

■

■

Extended Range 0-50 Maximum PSI

10. Accessories

R

■

■

Positioning Relay __________________________________

■

■

I/P Transducer _____________________________________

■

■

I/P and Positioner Combination

■

■

Gauge Set

11. Part # _______________________________________________

NOTES

R

Required Information

E/O

Either/Or Information

If the required flow rate through the valve (Capacity, Item #3) is

not known, it can be calculated from the Process Load

Information (Item #4).

N

Nice To Have Information

Pressure drops across the valve can be assumed if they are not

specified by the customer.

Selecting the correct valve size and type is extremely important in order to maintain accurate control and long valve life. To

get the valve that will best meet your needs, please be sure to answer every question noted as “Required” on this Application

Data Sheet.

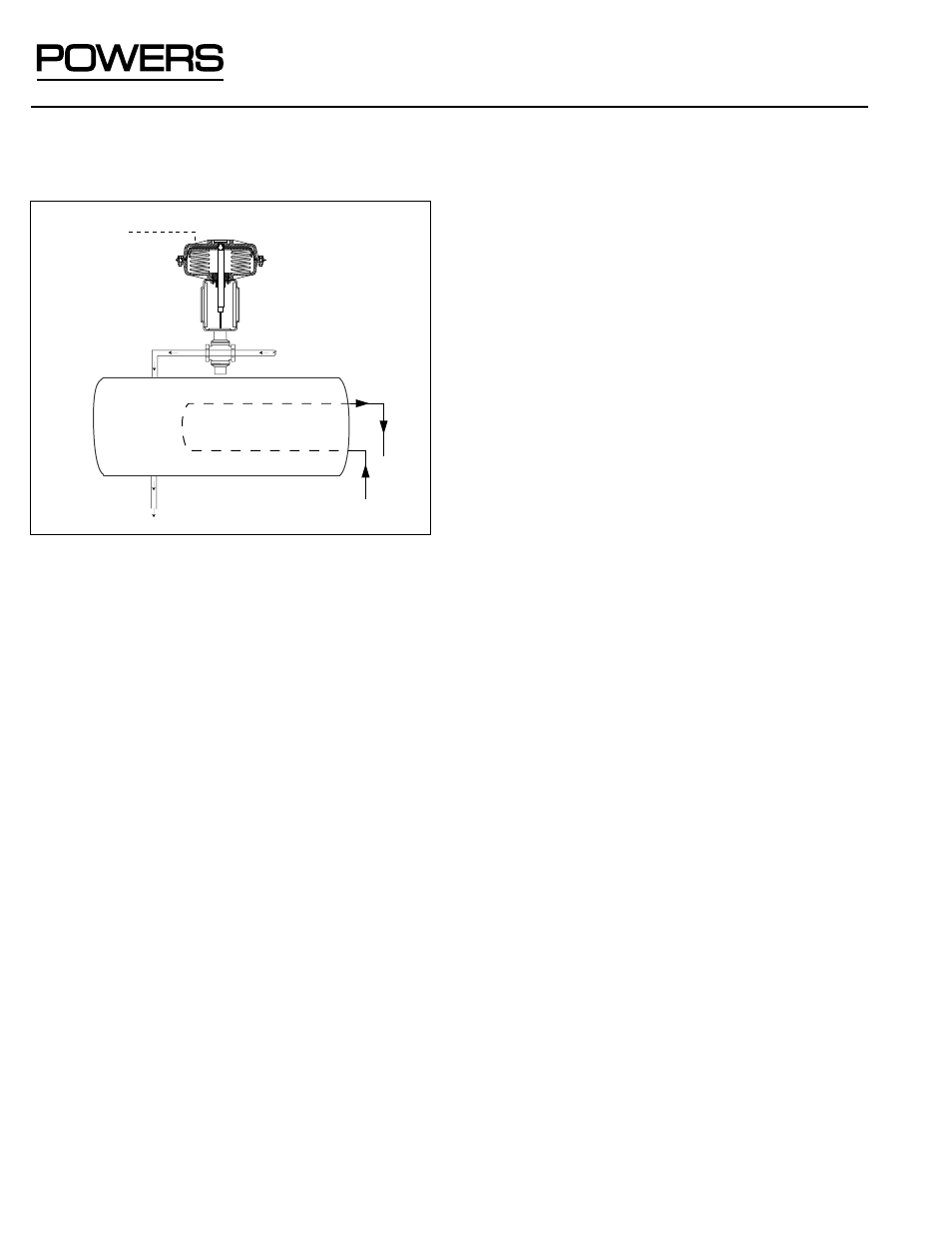

Media Through Valve

Signal

to Actuator

42sq. in.

Flowrite

shown

Process

Load

N.O. & N.C.

Sample Application

A Watts Industries Co.

Control Valve

Application Data Sheet

Form ADS#11FW

Flowrite

Page 2 of 2

ADS#11FW 0247

Printed in U.S.A.