Powers 450-e420E HydroPanel II Shower System with HydroGuard e420 Thermostatic Valve User Manual

Page 3

3

What to look for if:

1. The flow of the water is less then desired.

a. Valves upstream from supply not fully open.

b. Low supply pressure.

c. Accumulation of lime deposit in hot water pipes, restricting

the flow of the hot water

d. Showerhead clogged. Remove and clean.

e. Checkstops may not be fully open.

2. Flow of water is completely shut off.

a. Valves upstream from supply completely closed.

b. Failure of hot or cold water supply pressure.

c. Checkstops closed.

3. If the water varies in temperature.

a. Lime deposit may have accumulated in the hot water

pipes, restricting water flow.

b. Thermostatic wax element may have failed. Replace wax

element.

c. The inlet water supplies may be connected to the wrong

ports. Remove HydroPanel

™

II and re-install.

d. There may be extreme pressure variation in the water sup-

ply lines. Check with plumber or plumbing engineer.

4. Flow of water continues when valve is shut off.

a. Worn shutoff disc. Replace cartridge.

5. Checkstops leak or they won't shut off.

a. The checkstops may be damaged. Replace with check-

stop replacement kit.

6. Maximum temperature is too low.

a. Accumulation of lime deposit in hot water pipes, restricting

the flow of the hot water.

b. The concealed maximum temperature limit stop is not at

its maximum adjustment. Set the maximum temperature

limit stop.

c. Hot water temperature is too low.

Troubleshooting

n

Maximum temperature setting adjustment must be set on job site

(See Fig. 5). The high temperature limit stop is threaded into the

bonnet and is turned counterclockwise for an increased setting

and clockwise for a decreased setting. Powers recommends a

maximum setting of 110°F (43°C). To adjust temperature, rotate

handle to the maximum desired outlet temperature, screw tem-

perature limit stop until it touches stem's shoulder. Close valve

and open it to verify setting.

Before servicing checkstops or piping, turn off water supplies

upstream. To access the checkstops, remove handle, name

plate and cover plate.

At least every twelve months, open up the checkstops and

check for the free movement of the poppet.

Before servicing the valve, either turn off the water supply

upstream or close the checkstops. To close the checkstops,

turn the adjustment screw on each stops clockwise.

Every six month, check and adjust the handle rotation setting.

Every twelve months, remove the valve bonnet and check the

internal components for the freedom of movement.

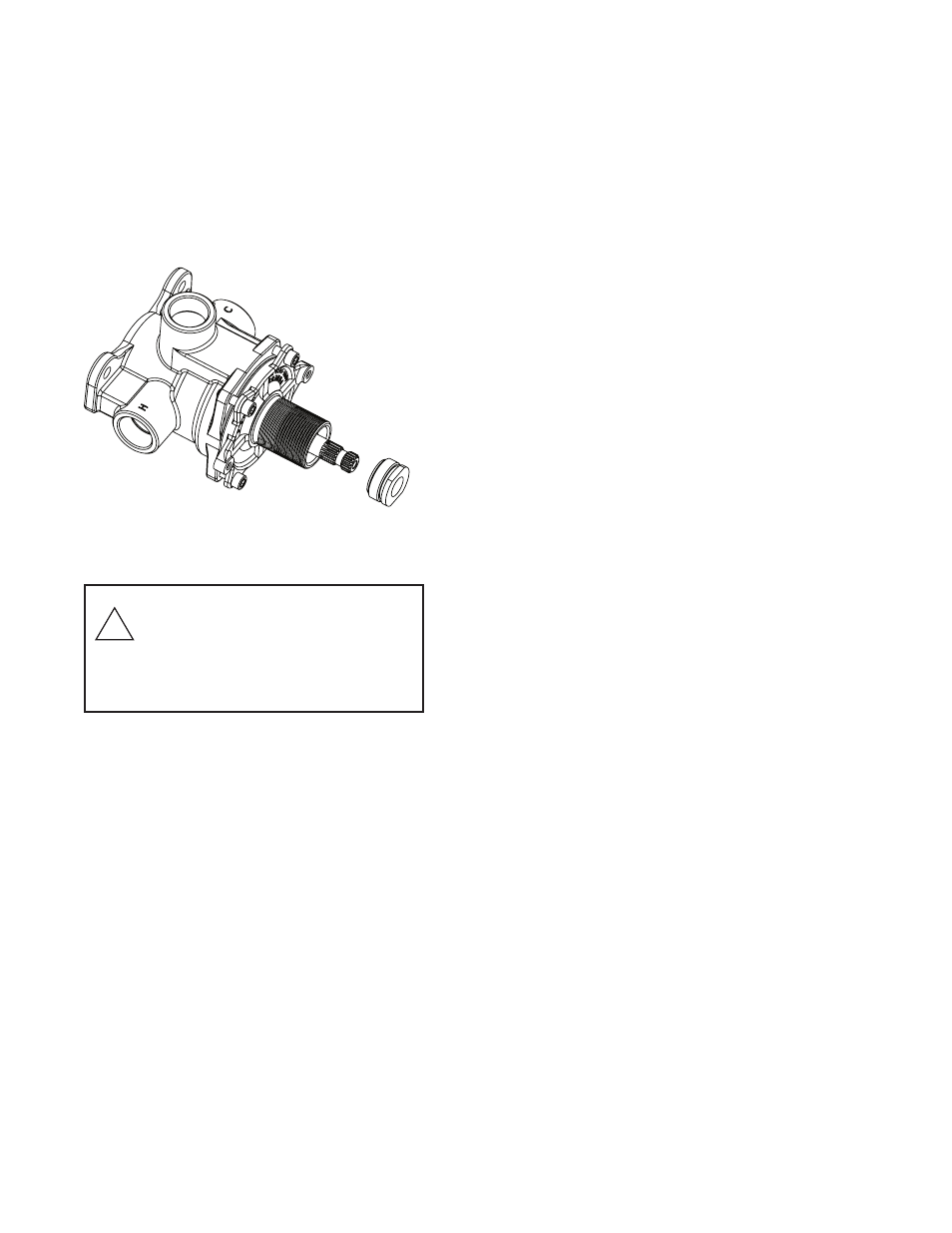

High Temperature Limit Stop Adjustment

n

Servicing

n

Figure 5

MAXIMUM

TEMPERATURE

LIMIT STOP

WARNING

Always verify the maximum tempera-

ture setting to the valve after any

changes are made. This should also be

checked as a part of a facilities maintenance/

safety program.

!