Maintenance/checkout – Banner RP-RM83F Rope Pull Switches User Manual

Page 6

Wiring

These switch models have redundant pairs of safety contacts, so they may be wired for either single-channel or dual-

channel output to a safety module or E-stop circuit. Monitor contacts may be wired as desired to an external alarm device.

CAUTION: Proper Wiring. Maximum tightening torque of contact screws is specified at 0.8 Nm; do not

over-tighten. Before closing the front cover, verify no wires are trapped. Do not operate the rope pull

without properly closing the cover.

Single-Channel Output: Wire contacts 11/12 together in series to the input of a safety module or E-stop circuit.

Dual-Channel Output: Wire contacts 11/12 independently to the two safety module inputs.

Warning Signal. Switch models RP-RM83F-...E provide a

24 V dc solid-state “warning signal” output, which signals

when the rope tension is either too high or too low, before

the safety contacts open and the switch latches OFF. This

solid-state switch is located inside the wiring chamber next

to the safety output contacts.

–

+

1

2

3

0 V dc

+24 V

1

2

3

Load

Figure 11. Warning Signal Electrical Connections

Manual/Latch Reset

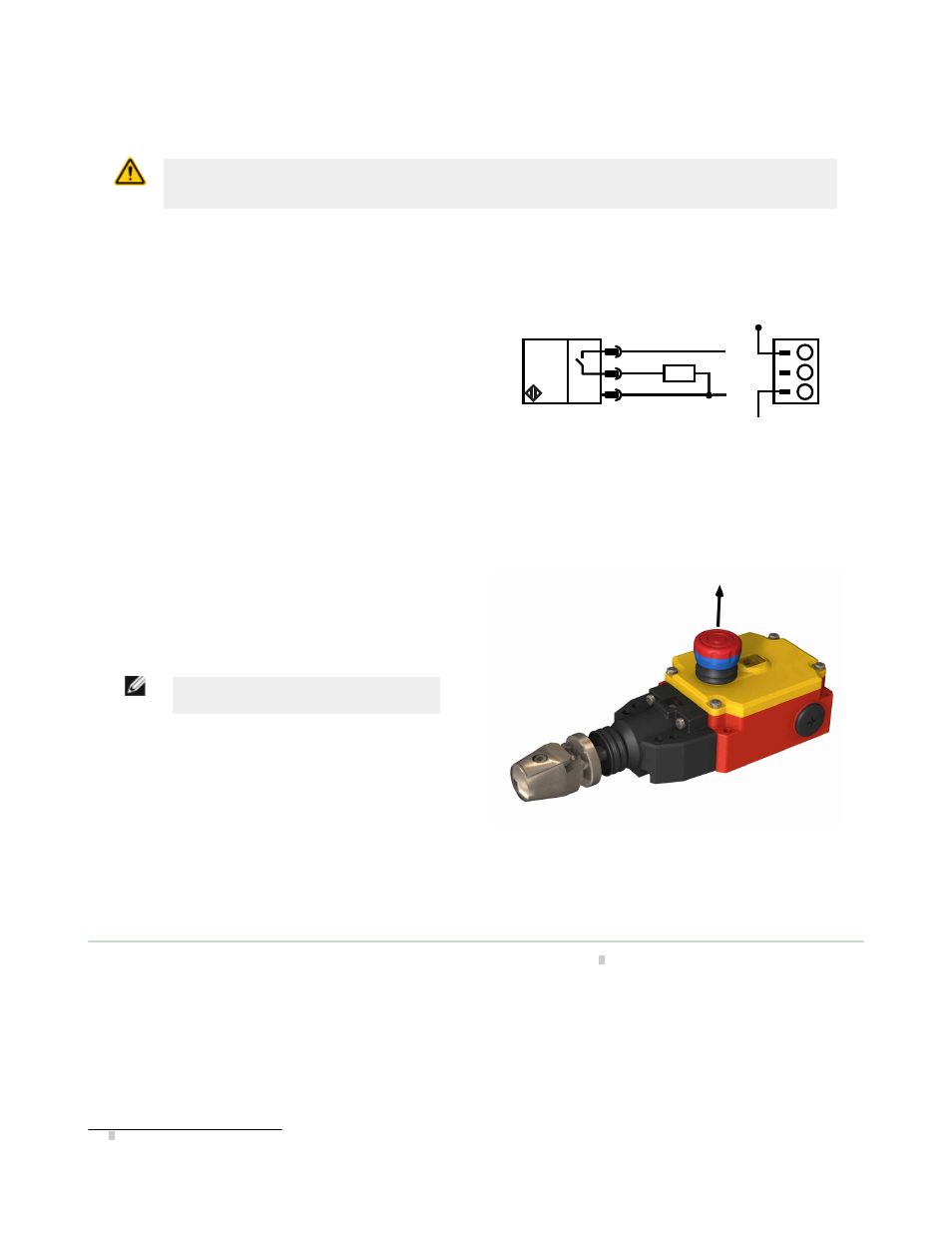

E-Stop and Latch Reset. Following the rope pulling/

breaking or the E-stop button being pressed, the latch must

be manually reset. The E-stop can be reset only when

proper tension is indicated. Pull the red E-stop button until

the switch Status indicator changes from Yellow to Green

and the latch makes an audible “click,” indicating that the

latch has been reset.

NOTE: Proper rope tension must be

displayed before the latch can be reset.

Figure 12. Resetting the Latch

Maintenance/Checkout

At switch installation or replacement and at machine set up, a Designated Person

3

must test each switch for proper

machine shutdown response and check the switch(es) and installation for proper operation, physical damage, mounting

(looseness), and excessive environmental contamination. This must also take place on a periodic schedule determined by

the user, based on the severity of the operating environment and the frequency of switch actuations. Adjust, repair, or

replace components as needed. If inspection reveals contamination on the switch, thoroughly clean the switch and

eliminate the cause of the contamination. Replace the switch and/or appropriate components when any parts or

assemblies are damaged, broken, deformed, or badly worn; or if the electrical/mechanical specifications (for the

environment and operating conditions) have been exceeded. Always test the control system for proper functioning under

machine control conditions after performing maintenance, replacing the switch, or replacing any component of the switch.

Additional items that should be included in the checkout and/or regularly scheduled maintenance of a rope pull system:

3 A Designated Person is identified in writing by the employer as being appropriately trained to perform a specified checkout procedure.

RP-RM83F Heavy-Duty Rope Pull Emergency Stop Switches

6

www.bannerengineering.com - tel: 763-544-3164

P/N 141245 Rev. C