Electrical installation, Tensioning the rope – Banner RP-RM83F Rope Pull Switches User Manual

Page 5

Tensioning the Rope

After the rope span components are installed, apply tension to the rope until the arrows in the tensioning indicator are

centered on the line in the tension indicator window. This indicates sufficient rope tension. (Contacts 11/12 will close.)

1. For models RP-RM83F-..LT and RP-RM83F-..LTE: Turn the external turnbuckle until the arrows are centered. For

models RP-RM83F-..LR and RP-RM83F-..LRE: Turn the shaft of the switch using a 17 mm wrench as shown, until

the arrows are centered.

2. Pull hard on the rope and reset the latch several times. If the arrows in the tensioning indicator window do not

return to the correct position (centered on the line in the window), further tighten or loosen the rope tension as

needed, then reset, until proper tension is shown.

3. Check the tension adjustment periodically to ensure proper operation.

Figure 6. Tension Indicator

Window: too little tension shown

Figure 7. Tension Indicator

Window: proper tension shown

Figure 8. Adjusting rope tension (models RP-RM83F-..LT

and-..LTE)

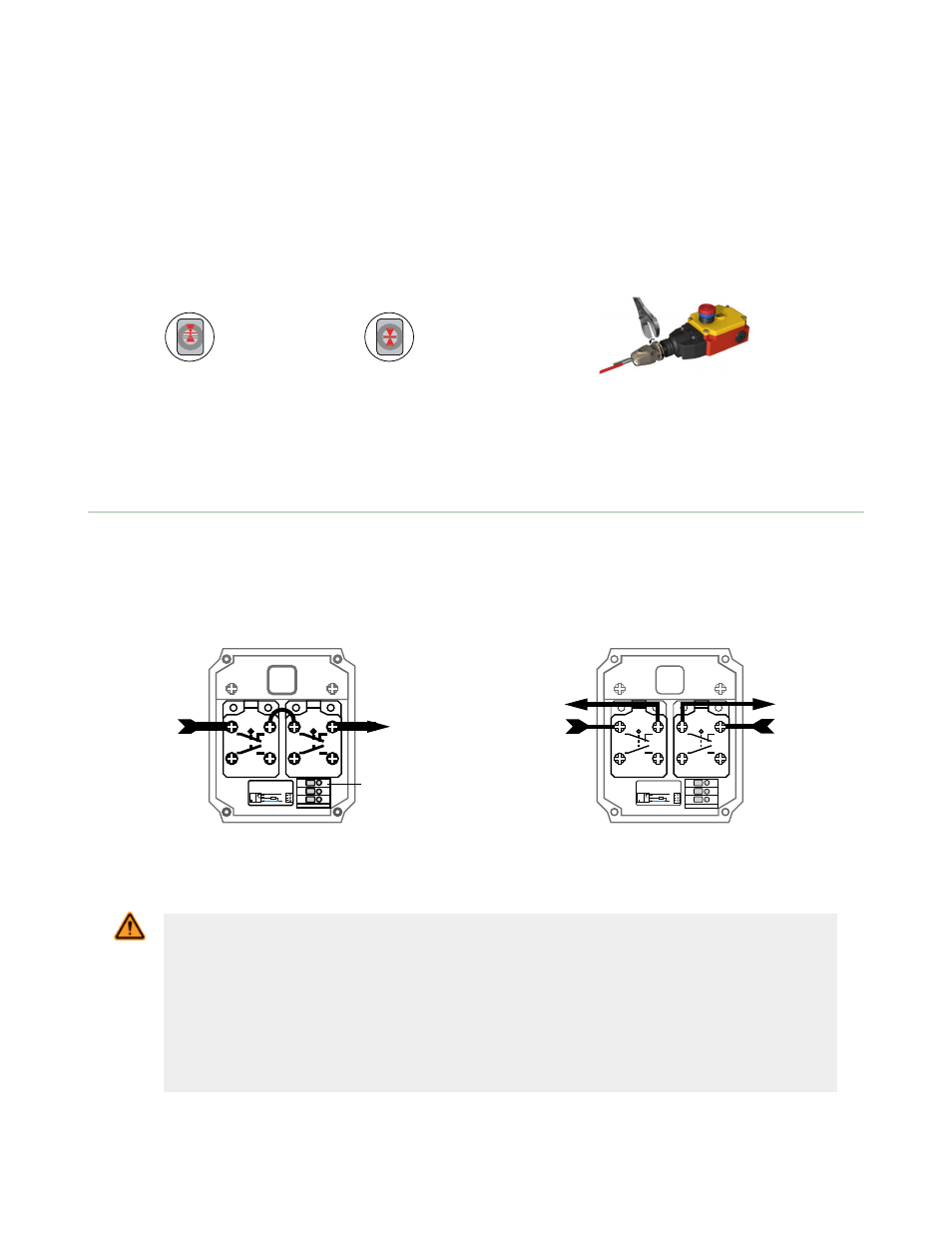

Electrical Installation

Accessing the Wiring Chamber

Access the wiring chamber by loosening the four corner screws to remove the front cover. Select the best wiring entrance

and thread in the ½" x 14 NPSM conduit adapter (supplied), or the optional M20 x 1.5 cable gland (see Accessories). Wire

the two switch contacts in series or independently.

11

12

23

24

11

12

23

24

–

+

1

2

3

1

2

3

Load

10-30 VDC

PNP

Warning Signal

Connections

Figure 9. Single-Channel Connection

11

12

23

24

11

12

23

24

–

+

1

2

3

1

2

3

Load

10-30 VDC

Channel A

Channel B

Figure 10. Dual-Channel Connection

WARNING: Shock Hazard and Hazardous Energy

Always disconnect power from the safety system (for example, device, module, interfacing,

etc.) and the machine being controlled before making any connections or replacing any

component.

Electrical installation and wiring must be made by Qualified Personnel and must comply with the

relevant electrical standards and wiring codes, such as the NEC (National Electrical Code), ANSI

NFPA79, or IEC 60204-1, and all applicable local standards and codes.

Lockout/tagout procedures may be required. Refer to OSHA 29CFR1910.147, ANSI Z244-1, ISO

14118, or the appropriate standard for controlling hazardous energy.

RP-RM83F Heavy-Duty Rope Pull Emergency Stop Switches

P/N 141245 Rev. C

www.bannerengineering.com - tel: 763-544-3164

5