Banner Compact Plastic Style Safety Interlock Switches User Manual

Page 2

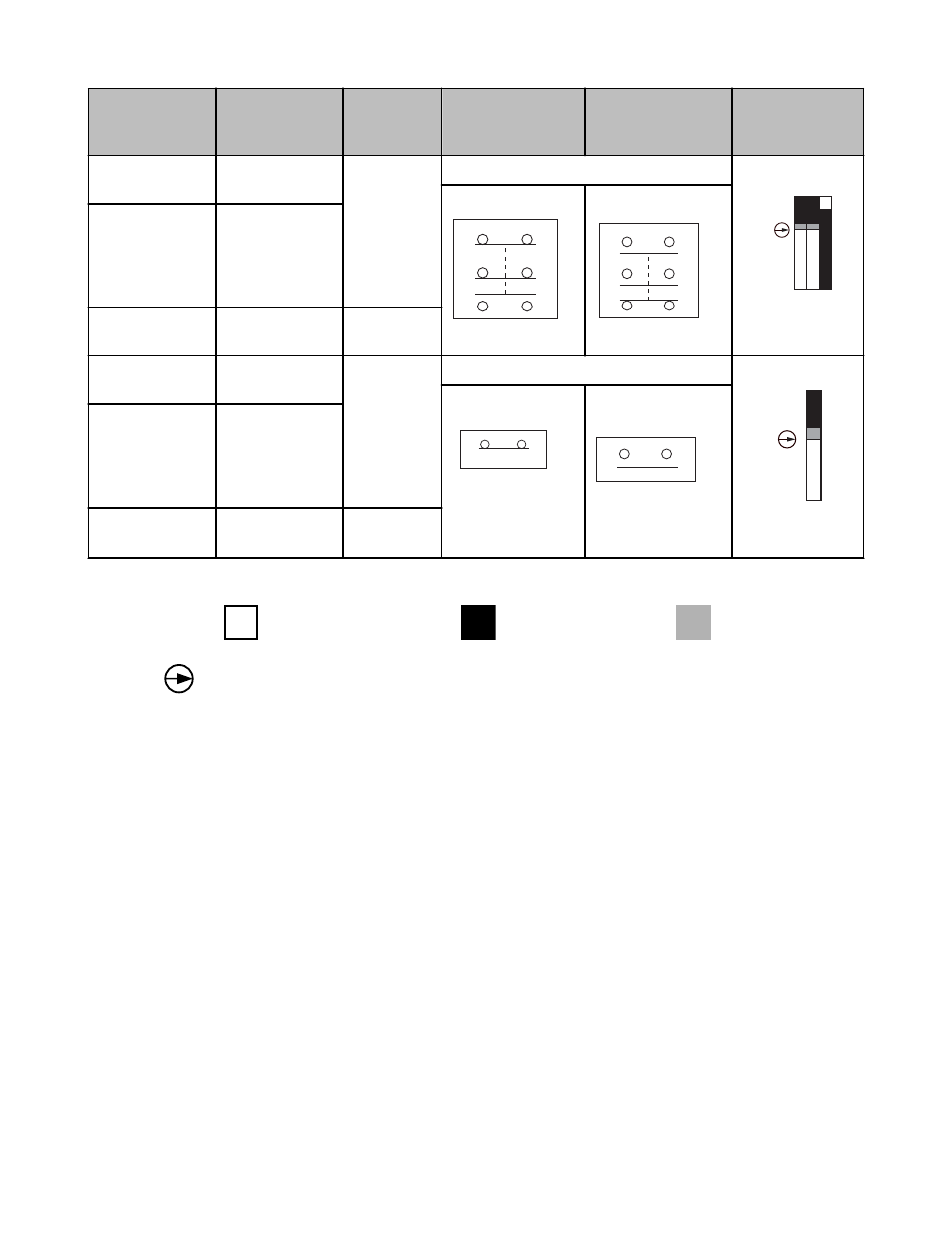

Kit Model *

Actuator Type *

Interlock

Body *

Contact Configura-

tion (Actuator Engag-

ed)

Contact Configuration

(Actuator Removed)

Switching Dia-

grams

SI-QS90MF

SI-QS-SSA-4 In-

Line Stamped

SI-QS90F

Two N.C. and One N.O. Contact

3.0 (0.12)

3.5 (0.14)

0 (0)

15-16

25-26

33-34

5.0 (0.20)

21.5 (0.85)

mm (in)

Engaged

Disengaged

Safety

Safety

Monitor

25

26

33

34

15

16

25

26

33

34

15

16

SI-QS90MFF (Direct

replacement for

models SI-

QS90MRHF and SI-

QS90MRVF)

SI-QS-SSU Flexible

SI-QS90MFHF

(High Force) **

SI-QS-SSA In-Line

Die-Cast

SI-QS90FSI-

QS90F

SI-QS75MC

SI-QS-SSA-4 In-

Line Stamped

SI-QS75C

One N.O. Contacts

6.2 (0.24)

0 (0)

11-12

7.2 (0.28)

21.5 (0.85)

mm (in)

Engaged

Disengaged

Safety

11

12

11

12

SI-QS75MFC (Di-

rect replacement for

models SI-

QS75MRHC and SI-

QS75MRVC)

SI-QS-SSU Flexible

SI-QS75MCHF

(High Force) **

SI-QS-SSA In-Line

Die-Cast

SI-QS75CHF

Switching Diagram Key

Contacts:

Open

Closed

Transition

This symbol (

) is used in the switching diagrams to identify the point in actuator travel where the normally closed safety contact is

fully open.

* A kit contains an interlock and actuator. Individual interlock bodies or actuators are for replacement purposes only. See the warning in

** High Force: 50 N (11.25 lbf) holding force integrated into switch. Use SI-QS-SSA In-Line Actuator only; also see accessory SI-QS-100.

Important Information Regarding the Use of Safety Switches

In the United States, the functions that Banner safety switches are intended to perform are regulated by the Occupational Safety and

Health Administration (OSHA). Whether or not any particular safety switch installation meets all applicable OSHA requirements depends

upon factors that are beyond the control of Banner Engineering Corp. These factors include the details of how the safety switches are

applied, installed, wired, operated, and maintained.

Banner Engineering Corp. has attempted to provide complete application, installation, operation, and maintenance instructions. This in-

formation is found in the instruction manual packaged with each safety switch. In addition, we suggest that any questions regarding the

use or installation of safety switches be directed to the factory applications department at the telephone numbers or address shown

below.

Banner Engineering Corp. recommends that safety switches be applied according to the guidelines set forth in international (ISO/IEC)

standards listed below. Specifically, Banner Engineering Corp. recommends application of these safety switches in a configuration which

meets safety category 4, per ISO 13849 (EN954-1).

In addition, the user of Banner safety switches has the responsibility to ensure that all local, state, and national laws, rules, codes, and

regulations relating to the use of Banner safety switches in any particular application are satisfied. Extreme care is urged that all legal

requirements have been met and that all installations and maintenance instructions are followed.

Application Assistance

Toll Free: 1-888-3-SENSOR (1-888-373-6767)

Machine Safety Switches

2

www.bannerengineering.com - tel: 763-544-3164

P/N 049370 Rev. F