Configuration, Safety interlock switch requirements – Banner ES-FA-6G Safety Module User Manual

Page 3

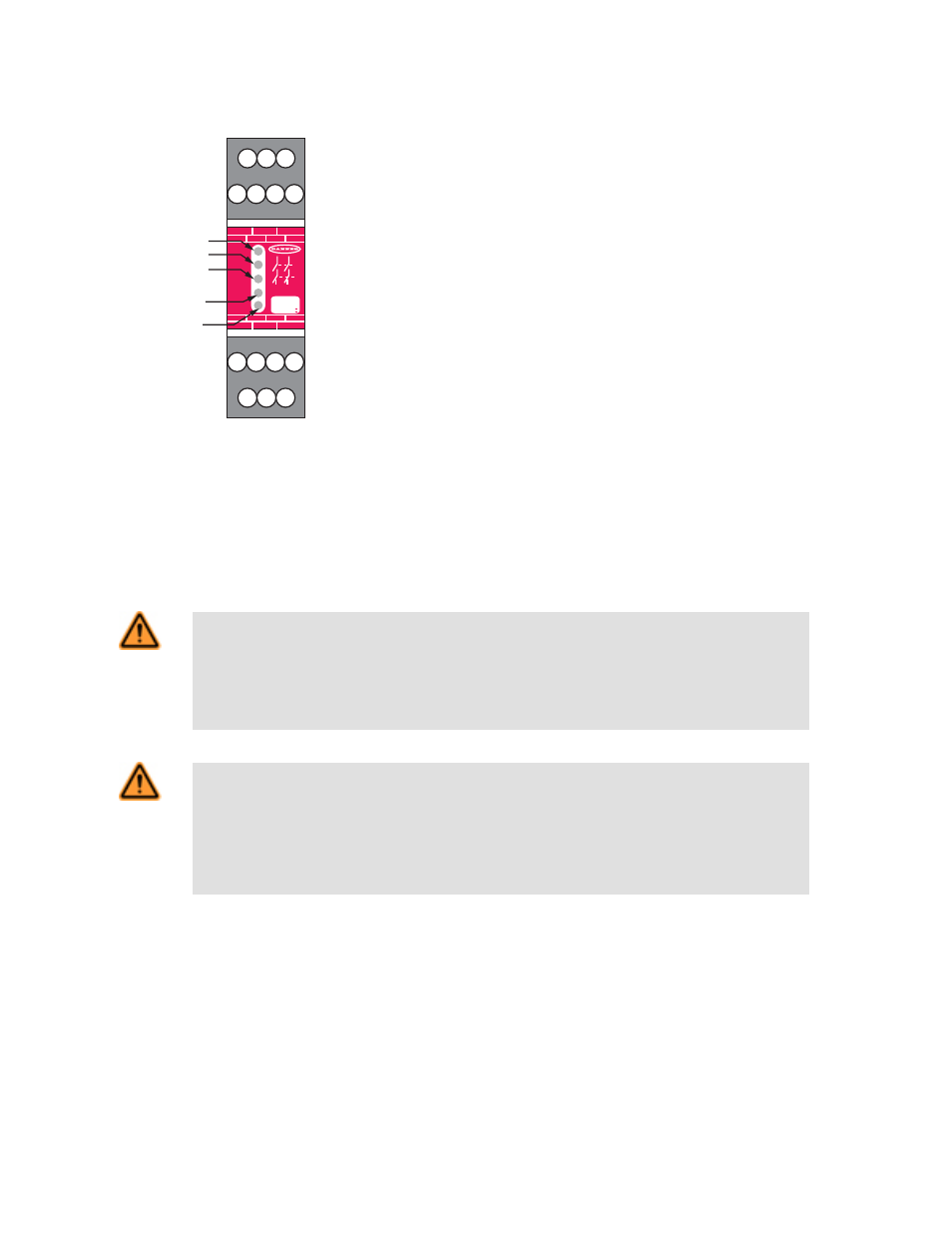

Configuration

S21

A1

S11

S13

S23

S21

S22

13

23

Y1

Y2

14

24

A2

K1

K2

14 24

Machine

Safety

GM-FA-10J

Power

Fault

In 1

In 2

Output

Power ON

(green)

Input 1

Active (green)

Fault (red)

Input 2

Active (green)

Outputs

Active (green)

S12

S13

S11

Y1

23

13

A1

A2

24

14

Y2

S22

S21

S23

Figure 1. GM-FA-10J Features and Terminal Lo-

cations

The Safety Module may be configured via DIP switches for two-channel (redundant

switches on a single guard), or one-channel operation (individual switches on two

guards). In two-channel operation, each channel must switch within 3-second si-

multaneity of the other when the guard closes. If not, the guard must be re-opened

and closed until the timing requirement is met. When the guard opens, the two

channels operate concurrently (both channels must switch, but without the timing

requirement).

In one-channel operation, each channel operates individually, except to reset the

device (in which case both guards must be closed). If only one switch is being

monitored, the closed input of the unused channel must be jumpered (S11/S13 or

S21/S23).

The reset function has two options, selected by DIP switch: Automatic reset or

Monitored Manual reset. See

Figure 7. Wiring to the guarded machine

9 for configuration information.

The reset input also can be used for an External Device Monitoring (EDM) circuit.

The EDM circuit consists of a normally closed, force-guided contact from each de-

vice being controlled by the Safety Module, all wired in series with the Reset button

(if used) and terminated at terminals Y1 and Y2. See

Figure 6. Alternate wiring for

two-channel monitoring of multiple guards

on page 8 for further information.

The output of the Safety Module consists of two redundant output switching chan-

nels, each of which is the series connection of two forced-guided relay contacts

(K1 and K2 in

Figure 6. Alternate wiring for two-channel monitoring of multiple

on page 8). Each of the switching outputs is rated for up to 250V ac at

up to 6 amps.

WARNING: Hazard Point

It must not be possible for personnel to reach any hazard point through an opened guard (or any

opening) before hazardous machine motion has completely stopped.

Please reference OSHA CFR 1910.217 and ANSI B11 standards for information on determining safety

distances and safe opening sizes for your guarding devices.

WARNING: Safety Categories

The level of safety circuit integrity can be greatly impacted by the design and installation of the safety

devices and the means of interfacing of those devices. A risk assessment must be performed to deter-

mine the appropriate safety circuit integrity level or safety category as described by ISO 13849-1

(EN 954-1) to ensure that the expected risk reduction is achieved and that all relevant regulations

and standards are complied with.

Safety Interlock Switch Requirements

The following general requirements and considerations apply to the installation of interlocked guards and gates for the purpose of safe-

guarding. In addition, the user must refer to the relevant regulations to be sure to comply with all necessary requirements.

Hazards guarded by the interlocked guard must be prevented from operating until the guard is closed; a stop command must be issued to

the guarded machine if the guard opens while the hazard is present. Closing the guard must not, by itself, initiate hazardous motion; a

separate procedure must be required to initiate the motion. The safety switches must not be used as a mechanical or end-of-travel stop.

The guard must be located an adequate distance from the danger zone (so that the hazard has time to stop before the guard is opened

sufficiently to provide access to the hazard), and it must open either laterally or away from the hazard, not into the safeguarded area. The

guard also should not be able to close by itself and activate the interlocking circuitry. In addition, the installation must prevent personnel

from reaching over, under, around or through the guard to the hazard. Any openings in the guard must not allow access to the hazard

GM-FA-10J Gate Monitoring Safety Module

P/N 060998 Rev. F

www.bannerengineering.com - tel: 763-544-3164

3