Configuration – Banner ES-FA-6G Safety Module User Manual

Page 10

• A resistance or similar damping device capable of dissipating the energy of surges

When switching inductive ac loads, it is good practice to protect the Safety Module outputs by installing appropriately-sized arc suppres-

sors. However, if arc suppressors are used, they must be installed across the load being switched (e. g., across the coils of external

safety relays), and never across the Safety Module’s output contacts (see WARNING, Arc Suppressors).

Configuration

WARNING: Reset Routine Required

U.S. and international standards require that a reset routine be performed after clearing the cause of a

stop condition (for example, arming an E-stop button, closing an interlocked guard, etc.). Allowing the

machine to restart without actuating the normal start command/device can create an unsafe condi-

tion which could result in serious injury or death.

WARNING: Reset Switch Location

All reset switches must be accessible only from outside, and in full view of, the hazardous area.

Reset switches must also be out of reach from within the safeguarded space, and must be protec-

ted against unauthorized or inadvertent operation (for example, through the use of rings or guards). If

any areas are not visible from the reset switch(es), additional means of safeguarding must be provided.

Failure to do so could result in serious bodily injury or death.

Manual Reset and Reset Switch Connection

The reset switch must be capable of reliably switching 15 to 30V dc at 5 to 50 mA. As

shown in

Figure 7. Wiring to the guarded machine

on page 9, the reset switch connects

between terminals Y1 and Y2 of the Module. The reset switch must be located outside of –

and not accessible from – the area of dangerous motion, and it must be positioned so the

switch operator can see all areas of dangerous motion during the reset procedure (see

Warning).

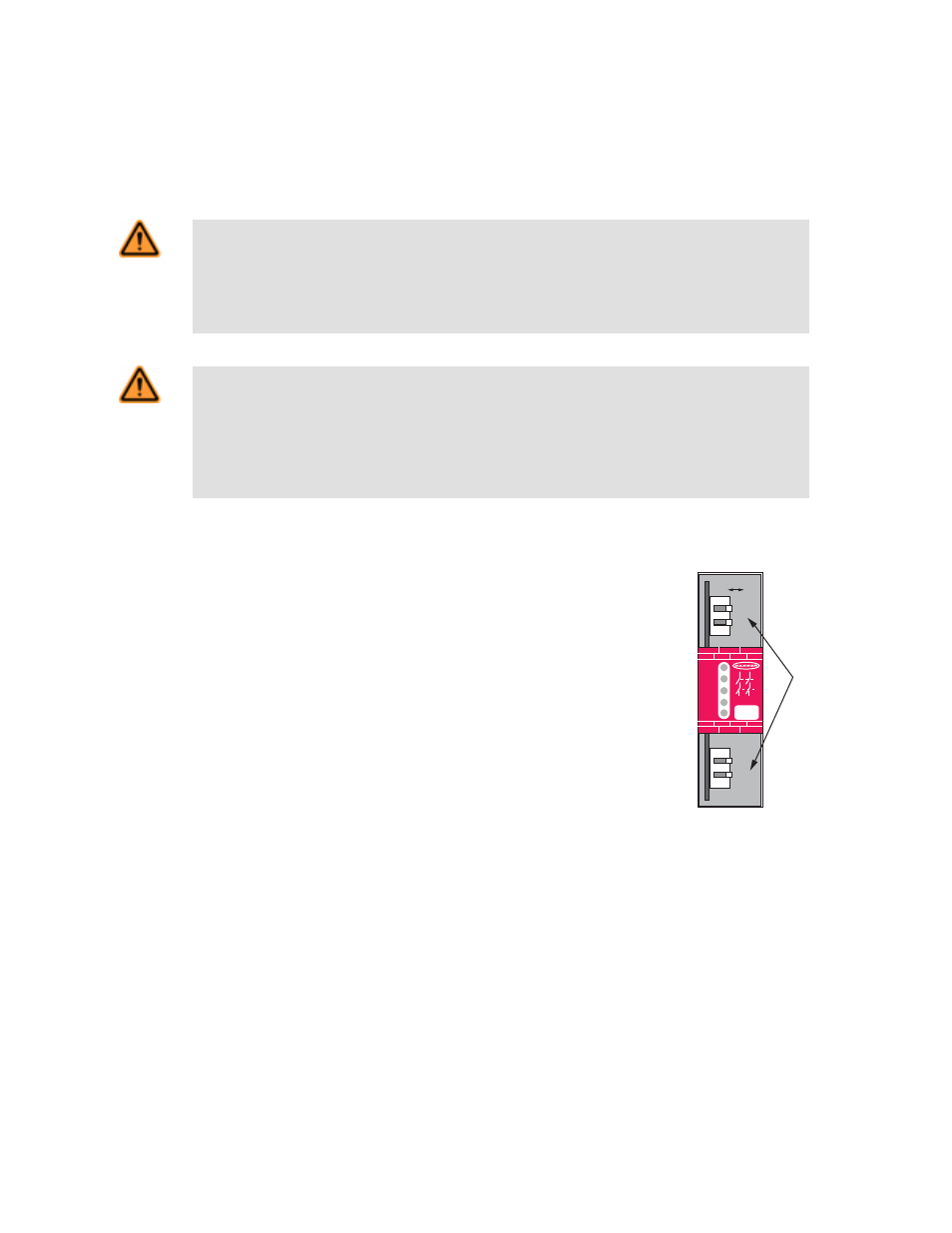

To configure the Module for Manual Reset, set switches S1.2 and S2.2 in banks A and B to

OFF. The reset switch may be any mechanical normally open switch, but should be a mo-

mentary switch or a two-position keyed switch. To reset the Module, both guards must be

closed, at which time the output LED will flash (signaling that the reset switch must be cy-

cled). This action is a monitored manual reset (open-closed-open), where the “closed”

phase is approximately 0.25 to 2 seconds long.

S21

A1

S11

S13

S23

S21

S22

13

23

Y1

Y2

14

24

A2

K1

K2

14 24

Machine

Safety

GM-FA-10J

Power

Fault

In 1

In 2

Output

DIP

Switch

Bank "A"

S1.1

S1.2

DIP

Switch

Bank "B"

S2.1

S2.2

S1.1/S2.1 OFF* – 2-Channel

ON – 1-Channel

S1.2/S2.2 OFF* – Manual Reset

ON – Auto Reset

* Factory Default

NOTE: Corresponding DIP switches

in Banks A and B must be set identically.

OFF

ON

Shown

with

terminal

blocks

removed

Figure 8. DIP switch configuration set-

tings for reset mode and 1- or 2-chan-

nel operation

Automatic Reset Mode

To configure the Module for Automatic Reset, set switches S1.2 and S2.2 in Banks A and B to ON. If no MPCE contacts are monitored,

install a jumper between terminals Y1 and Y2 (see

Figure 7. Wiring to the guarded machine

on page 9). The Safety Module will reset

(and its outputs will energize) as soon as the guards return to their closed position.

Automatic Reset is useful for some automated processes. However, if Automatic Reset is used, an alternate means must be provided to

prevent resumption of hazardous machine motion until an alternate reset procedure is performed. The alternate means must include a

GM-FA-10J Gate Monitoring Safety Module

10

www.bannerengineering.com - tel: 763-544-3164

P/N 060998 Rev. F