Initial checkout procedure – Banner ES-FA-6G Safety Module User Manual

Page 11

Reset switch, located outside the area of dangerous motion, and positioned so that the switch operator can see all areas of dangerous

motion during the reset procedure.

1-Channel or 2-Channel Input

The Safety Module may be configured for 1-channel (“single channel”) or 2-channel (“dual channel”) operation by setting DIP switches

S1.1 and S2.1 in Banks A and B. In 1-channel operation (S1.1 and S2.1 – ON), the input channels function independently. The two

guards can be monitored individually, but both channels must be in the closed position for the Safety Module to be reset.

In 2-channel operation ( S1.1 and S2.1 – OFF) the input channels must function together. Both channels must switch within a 3-second

simultaneity of the other when the guard closes. If not, the guard must be re-opened and closed until the timing requirement is met. When

the guard opens, the channels function concurrently (both must open, but without the timing requirement).

In either configuration, the “closed” inputs of each channel must be closed before the Safety Module can be reset (continuity S11 to S13

and S21 to S23). If in 1-channel mode and monitoring only one switch, a jumper must be installed at the unused input (e.g., S21 to S23;

see

Figure 2. Wiring to two 4-wire coded magnetic safety switches

Initial Checkout Procedure

CAUTION: Disconnect Power Prior to Checkout

Before performing the initial checkout procedure, make certain all power is disconnected from the

machine to be controlled.

Dangerous voltages may be present along the Safety Module wiring barriers whenever power to the ma-

chine control elements is ON. Exercise extreme caution whenever machine control power is or may

be present. Always disconnect power to the machine control elements before opening the enclo-

sure housing of the Safety Module.

WARNING: Multiple Safety Devices

When two or more safety devices are used, each device must be individually actuated, causing a

STOP or open-contact condition, then reset/rearmed and the Safety Module reset (if using manual

reset mode). This allows the monitoring circuits to check each device and its wiring to detect faults. Fail-

ure to test each device individually in this manner could result in undetected faults and create an

unsafe condition which could result in serious injury or death.

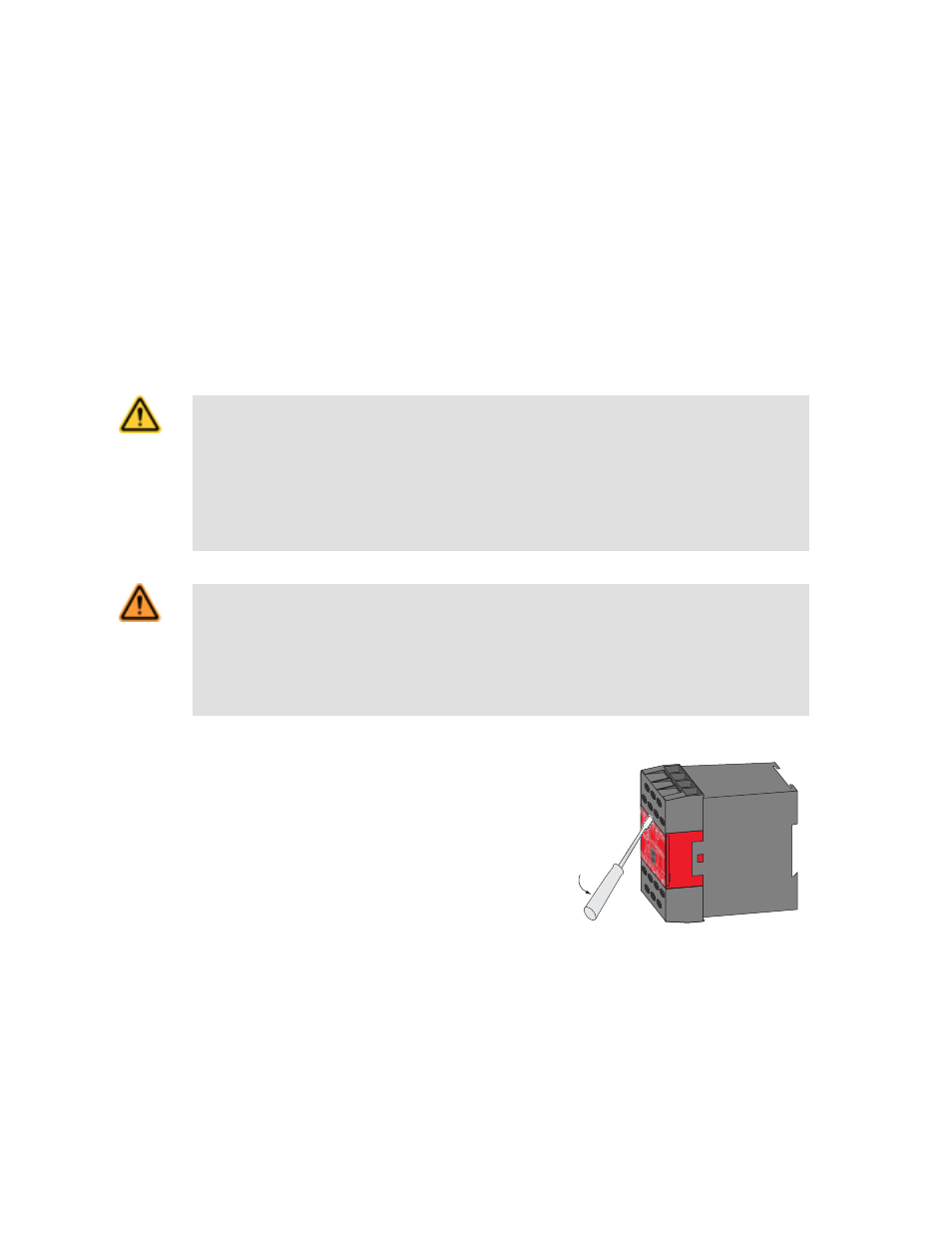

To remove a terminal block, insert a small screwdriver into the slot as shown, and

pry to loosen.

When reinserting the block, take care to slide the dovetail on the terminal block into

the slot on the frame.

Figure 9. Removal of terminal blocks

1. Remove power from the machine primary control elements (MPCEs).

2. Close all monitored guards. If the Module is wired to 1-channel input, the second input (S21/S23 or S11/S13) must be jumpered if

unused.

3. Apply input power (only) to the Gate Monitor Module at terminals A1 and A2 (see

Figure 7. Wiring to the guarded machine

on page

9). The following LEDs should come ON: Power, Input 1, Input 2

If the Power LED comes ON, but either or both Input LEDs are not ON, disconnect input power and check the wiring of the connected

switch(es) and/or the jumper. Check if the jumper is installed correctly on the unused input. Return to step 2 after the cause of the

problem has been corrected.

GM-FA-10J Gate Monitoring Safety Module

P/N 060998 Rev. F

www.bannerengineering.com - tel: 763-544-3164

11