Bryant 580J*04--12 User Manual

Page 26

26

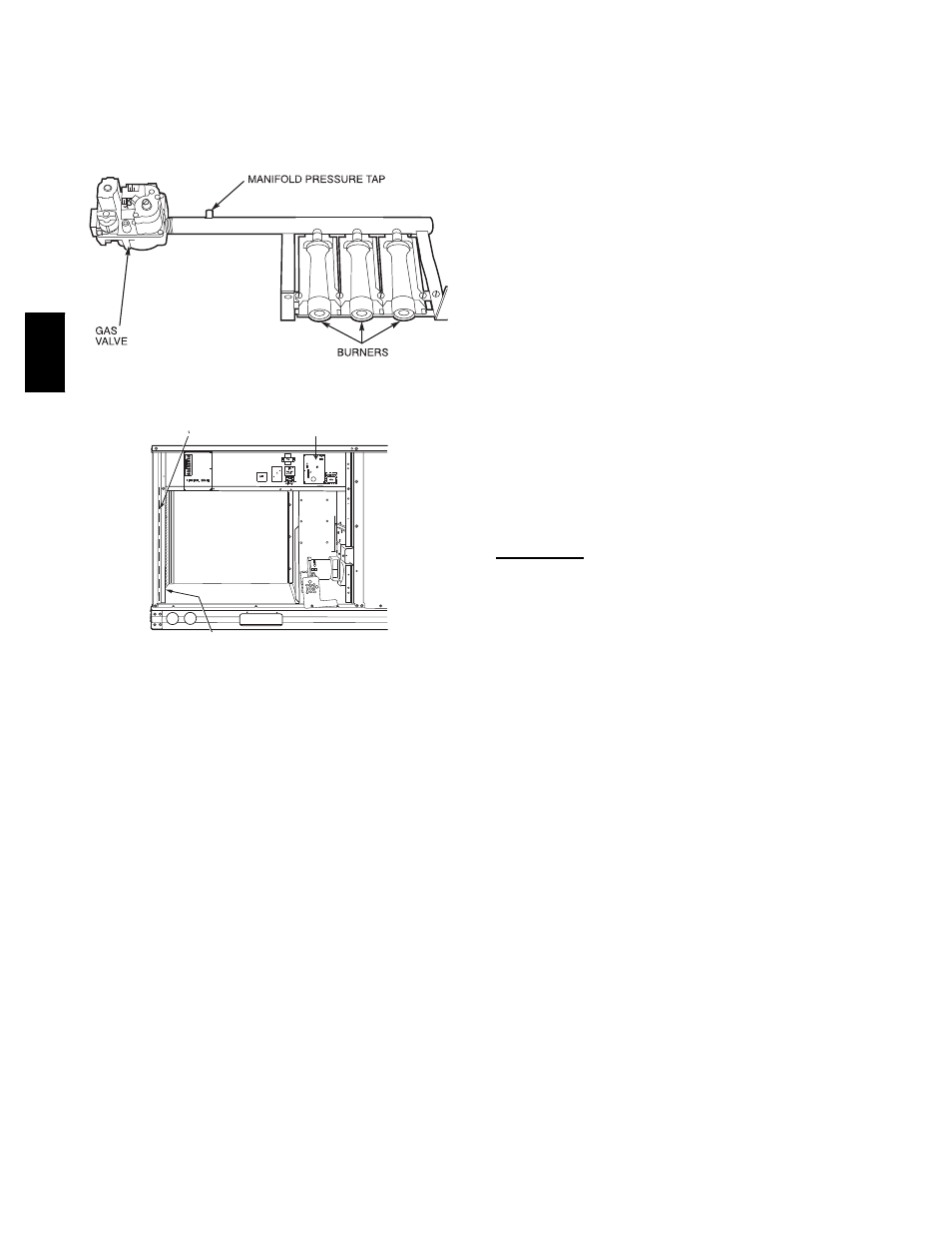

6. Reinstall burners on rack in the same locations as

factory--installed. (The outside crossover flame re-

gions of the outermost burners are pinched off to pre-

vent excessive gas flow from the side of the burner

assembly. If the pinched crossovers are installed

between two burners, the flame will not ignite prop-

erly.)

C06153

Fig. 33 -- Burner Tray Details

RACEWAY

INTEGRATED GAS UNIT

CONTROLLER (IGC)

HOLE IN END PANEL (HIDDEN)

C08454

Fig. 34 -- Unit Control Box/IGC Location

7. Reinstall burner rack as described in Removal and

Replacement of Gas Train section, above.

Gas Valve — All three--phase models (except Low NO

x

)

are equipped with 2--stage gas valves. Single--phase

models and all Low NO

x

models are equipped with

single--stage gas valves. See Fig. 37 for locations of

adjustment screws and features on the gas valves.

To adjust gas valve pressure settings:

IMPORTANT: Leak check all gas connections including

the main service connection, gas valve, gas spuds, and

manifold pipe plug. All leaks must be repaired before

firing unit.

Check Unit Operation and Make Necessary Adjust-

ments

NOTE: Gas supply pressure at gas valve inlet must be

within specified ranges for fuel type and unit size. See

Tables 4 and 5.

1. Remove manifold pressure tap plug from manifold

and connect pressure gauge or manometer. (See Fig.

33)

2. Turn on electrical supply.

3. Turn on unit main gas valve.

4. Set room thermostat to call for heat. If unit has two--

stage gas valve, verify high--stage heat operation be-

fore attempting to adjust manifold pressure.

5. When main burners ignite, check all fittings, mani-

fold, and orifices for leaks.

6. Adjust high--stage pressure to specified setting by

turning the plastic adjustment screw clockwise to in-

crease pressure, counter--clockwise to decrease pres-

sure.

7. For Two--Stage Gas Valves set room thermostat to

call for low--stage heat. Adjust low--stage pressure to

specified setting.

8. Replace regulator cover screw(s) when finished.

9. With burner access panel removed, observe unit heat-

ing operation in both high stage and low stage opera-

tion if so equipped. Observe burner flames to see if

they are blue in appearance, and that the flames are

approximately the same for each burner.

10. Turn off unit, remove pressure manometer and re-

place the 1/8 in. pipe fitting on the gas manifold. See

Fig. 33.

Limit Switch

Remove blower access panel. Limit switch is located on

the fan deck. See Fig. 28.

Burner Ignition

Unit is equipped with a direct spark ignition 100% lockout

system. Integrated Gas Unit Controller (IGC) is located in

the control box. See Fig. 34. The IGC contains a

self--diagnostic LED (light--emitting diode). A single LED

(see Fig. 38) on the IGC provides a visual display of

operational or sequential problems when the power supply

is uninterrupted. When a break in power occurs, the IGC

will be reset (resulting in a loss of fault history) and the

indoor (evaporator) fan ON/OFF times will be reset. The

LED error code can be observed through the viewport.

During servicing refer to the label on the control box

cover or Table 8 for an explanation of LED error code

descriptions.

If lockout occurs, unit may be reset by interrupting power

supply to unit for at least 5 seconds.

580J