Rockwell Automation SA3100 Distributed Power System Drv Config,Program User Manual

Page 150

Commissioning Procedure for Non-Constant Power Algorithim Operation

J-3

• After using the reference point data for Drive A (register 101), use the reference

point data for Drive B register (1101).

• Ensure that the vector orientation alignment request bit (bit 6, 0040h) is set in

register 1100.

• The IGNn! values for the A and B drives should be the same. The acquisition of

data should be done with both drives to verify that the magnitudes of the values are

similar. After the acquisition is done, the IGNn! values from Drive A should be used

for Drive B.

Present Commissioning Procedure -

SA3000 AC Vector w/ Constant Power:

Tuning the Magnetizing Current Reference Table - The latest version of the

SA3000 Constant Power Operating System has the capability of accomodating

temperature changes via modification of the slip value. This modification of the slip

value is accomplished through the use of a PMI reference magnetizing current table.

It enables the PMI to determine when a load change has occurred. When a load

change occurs, the output of the flux loop will increase. This increased output is

compared to the value from the reference table. The difference between the two

generates a change in slip. The change in slip causes a reduction in flux loop output,

which in turn, cause the flux loop output to be the correct value for the magnetizing

current value at that point in the speed range.

In order to tune or calibrate this table, a speed loop must be implemented in the UDC

module. This speed loop must be set up so that a value of 4095 counts of speed

reference corresponds to the maximum speed of the drive (i.e. four times the

maximum voltage speed).

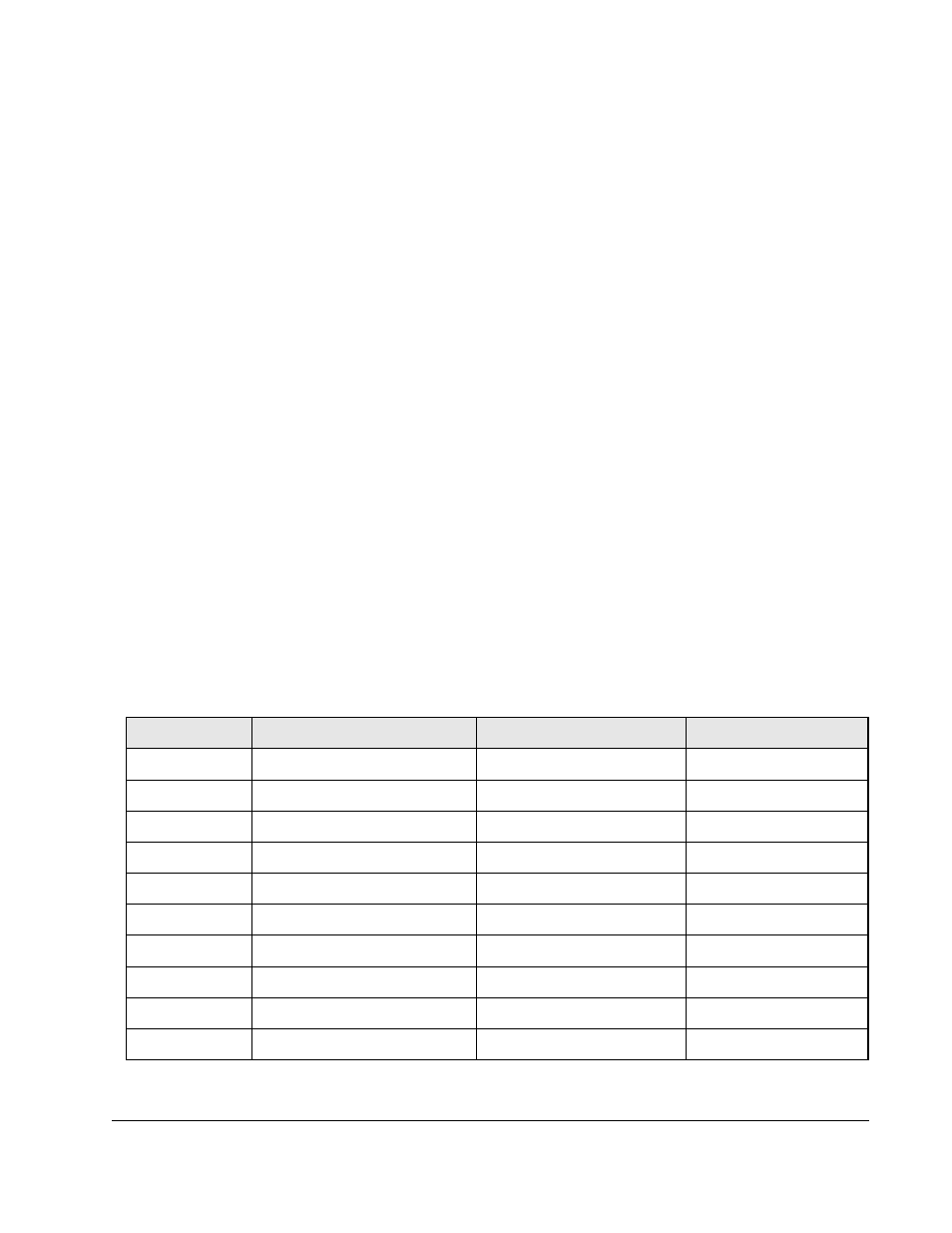

Using this speed loop, it is possible to utilize a maximum of 10 points in the speed

reference curve. You will need all ten reference points if you are using a four to one

range in your application. You do not need to use all ten reference points if your

application does not reach the four to one speed range. The following table indicates

the speed reference points at which data is obtained.

Ref. Point

Speed Reference Counts

Value Save Location

Units

One

409

Stator_ iZ_e1%

(RMS amps * 10)

Two

1023 (equal to max v speed)

IGN1!

(Note peak amps* 100)

Three

1125

IGN2!

Four

1227

IGN3!

Five

1329

IGN4!

Six

1635

IGN5!

Seven

1941

IGN6!

Eight

2247

IGN7!

Nine

2859

IGN8!

Ten

4095

IGN9!