4 choosing and using function blocks – Rockwell Automation T8094 8000 Series TMR System Safety Manual User Manual

Page 107

SAFETY MANUAL

D oc N umber T8094

I ssue 27 – June 2013

Page 86 of 103

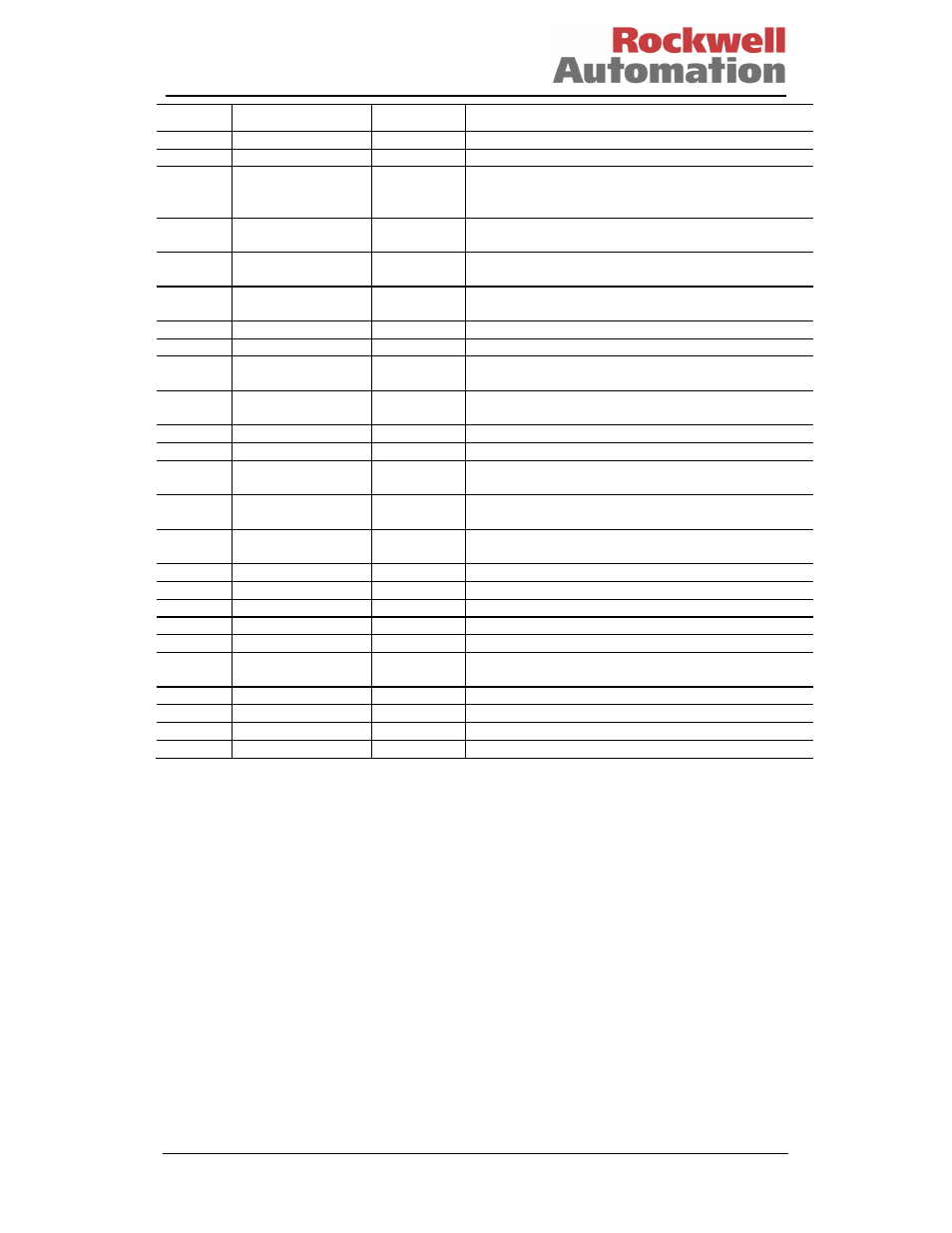

Term

Meaning or origin Type

Remarks

on slice B

FRQ

frequency

analogue

the frequency of scheduled tests

HR

hour (current time) analogue

the hour part of the current time of day, usually

taken from the real time clock of the TrustedTM

controller

IP

process input

analogue

output from termination assembly for an analogue

input to LFLT

IPA

input A

Boolean

output from termination assembly for digital input

slice to DIPT

IPB

input B

Boolean

output from termination assembly for digital input

slice to DIPT

IPV

input verification

Boolean

output from DIPT

LF

line fault

Boolean

output from LFLT to application

MDA

monitor

discrepancy A

Boolean

output from termination assembly A to RMET

MDB

monitor

discrepancy B

Boolean

output from termination assembly B to RMET

MTS

manual test start

Boolean

input used to start a test sequence

OC

open circuit

Boolean

output from LFLT to application

OCTHR

open circuit

threshold

analogue

input configuration parameter to LFLT

OPA

output A

analogue

coded output from RMET to control relay A, see

also PCK16

OPB

output B

analogue

coded output from RMET to control relay B, see

also PCK16

PCK16

packing of 16 bits

analogue

coded output from RMET to UNPACK16

PACK16 packing of 16 bits

analogue

coded output from PACK16 to RMET

RAT

request autotest

Boolean

output from DIPT to application

RST

reset

Boolean

input, resets the latched autotest faults

SC

short circuit

Boolean

output from LFLT to application

SCTHR

short circuit

threshold

analogue

parameter to configure high threshold of LFLT

STM

start time

analogue

the hour of the time of day when the first test starts

TA

test active

Boolean

shows when any test sequence is active

TRA

test relay A

Boolean

output, controls the autotest relay A

TRB

test relay B

Boolean

output, controls the autotest relay B

9.10.4 Choosing and Using Function Blocks

9.10.4.1 General Instructions

1. The function blocks are supplied by Rockwell Automation. You must use the function

blocks as supplied as they are not accessible and cannot be changed.

2. The migrated application must annunciate fault detection status. This will enable faulty

hardware to be replaced within the mean time to repair used for the module PFD

calculation.

3. The function blocks do not find some invalid configuration parameters, such as some

enumerations out of range. You must make sure that your application sends satisfactory

configuration data to the function blocks.

4. After the state of an output changes, the Trusted

TM

controller must wait for a suitable

settling time before reading the input associated with monitoring the same output. To do