Step 9: remove dc bus bars, Step 10: remove voltage supply cables – Rockwell Automation 20D Balancing Resistor Kit - 690V Fr 13 PowerFlex 700AFE & Fr 13/14 PowerFlex 700H/S User Manual

Page 6

6

Rockwell Automation Publication PFLEX-IN028A-EN-P - February 2012

Balancing Resistor Kit for 600/690V Frame 13 PowerFlex 700AFE and 600/690V Frame 13 and 14 PowerFlex 700H/700S AC Drives

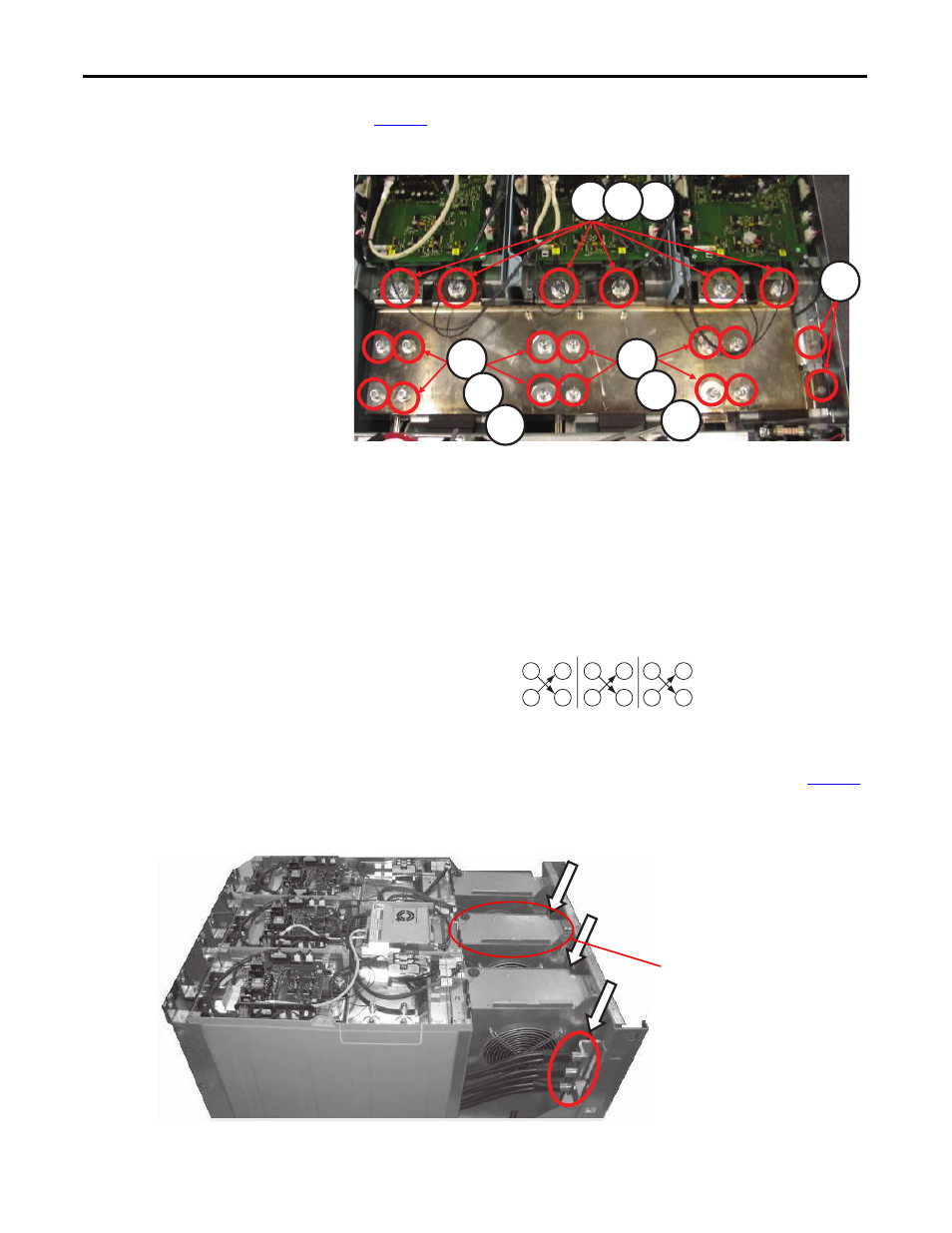

Step 9: Remove DC Bus Bars

See

Figure 8

and remove the DC bus bars and insulators between the bars.

Figure 8 - Removing DC Bus Bars

Step 10: Remove Voltage

Supply Cables

Unfasten the nine (9) screws, spring washers, and flat washers shown in

Figure 9

and remove the voltage supply cables.

Figure 9 - Removing Voltage Supply Cable Screws

1

4

5

5

3

2

6

7

6

7

9

12

10

11

5

8

6

7

1

4

2

3

1. Remove screws M10 x 25, 6 places; Tool: hexagonal wrench (size 17); Torque: 20 N•m.

2. Remove flat washers, 6 places.

3. Remove spring washers, 6 places.

4. Remove screws M6 x 12, 2 places; Tool: PZ2 – Head; Torque: 5 N•m.

5. Remove screws M8 x 25, 12 places; Tool: hexagonal socket head (size 6); Torque: 20 N•m.

6. Remove flat washers, 12 places.

7. Remove spring washers, 12 places.

NOTE: When reinstalling the DC bus bars, torque the bus bars using the following torque

pattern. This diagonal style of tightening the screws evenly secures the bus bars.

DC Bus Bar Torque Pattern

9 places

M10 x 30 hexagonal screws

Tool: hexagonal wrench (size 17)

Torque: 40 N•m

9 places

Remove spring washers

Remove flat washers

Voltage Feedback

Board Location

NOTE: When reinstalling, re-torque the

voltage supply cables from the bottom. An 18

mm wrench may need to be used if the cable

starts to twist when re-torquing the cables.