Rockwell Automation GV3000/SE AC Drive Ver. 6.06 Hdwe Ref., Installation, and Troubleshooting Manual User Manual

Page 61

Installing Input Power Wiring

5-5

5.4 Installing Power Wiring from the AC Input Line to the

Drive’s Power Terminals

Use the following steps to connect AC input power to the drive:

Step 1. Wire the AC input power leads by routing them according to drive type. Refer

to figures 4.1 through 4.7. Tables 3.3 through 3.8 contain the recommended

power wiring sizes.

Note that on 200-400 HP drives, knockouts for conduit installation are not

provided. If incoming power is 380 or 415 VAC, the fan transformer taps must

be changed before the power leads are connected. See section 5.6.

Step 2. Connect the three-phase AC input power leads (three-wire 380-460 VAC) to

the appropriate terminals.

On 1-60 HP drives, connect the AC input power leads to terminals R/L1,

S/L2, T/L3 on the power terminal strip.

On 60-150 HP drives, connect the AC input power leads to terminals 1L1,

1L2, and 1L3.

On 200-400 HP drives, connect the AC input power leads to terminals R, S,

and T.

Step 3. Tighten the AC input power terminals to the proper torque as shown in table

5.2.

!

ATTENTION: Do not route signal and control wiring with power wiring in

the same conduit. This can cause interference with drive operation.

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

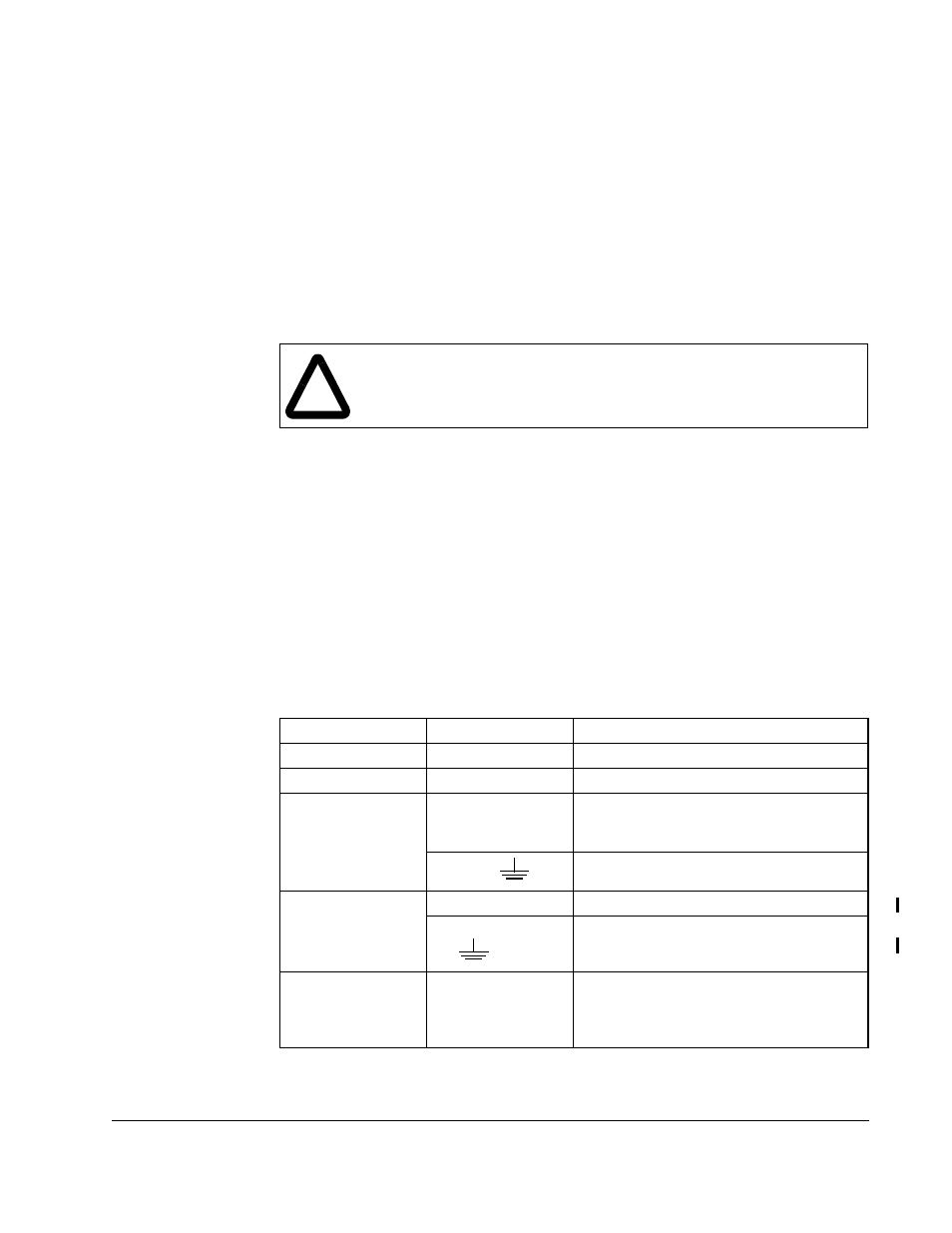

Table 5.2 – Terminal Tightening Torques

Drive

Terminals

Maximum Tightening Torque

1-25HP

All

1.08 Newton-meters (9.5 in-lb)

25-60HP

All

13.5 Newton-meters (10 ft-lb)

60-100HP

1L1, 1L2, 1L3

U, V, W

45,47

10 Newton-meters (7.4 ft-lb)

PE,

2.5 Newton-meters (1.8 ft-lb)

100-150HP

1L1, 1L2, 1L3, PE

34 Newton-meters (25 ft-lb)

U, V, W

, 45, 47

34 Newton-meters (25 ft-lb)

200-400HP

R/L1, S/L2, T/L3

U/T1, V/T2, W/T3

DC-, DC+

GND

34 Newton-meters (25 ft-lb)