Rockwell Automation 1771-SPI,D17716.5.122 SPI PROTOCOL INTERFACE User Manual

Page 49

Creating Command and Status Blocks

Chapter 4

4-13

Once you have successfully configured the SPI module with the MCC and

whenever you transfer the CCB to the SPI module, it responds by returning

Custom Configuration Status (CCS).

You must correct any detected errors as indicated by the CCS before you

can transfer data to devices whose configuration has been successfully

stored in the SPI module.

The CCS is returned to the PLC processor by the SPI module. To map the

CCS in your data table, use the same number of words as its corresponding

CCB. We repeat the CCS bit/word map from chapter 3.

Important: When the SPI module detects a fault in the CCB, it returns the

CCS with its status cleared, containing information only in words 1 and 3:

word 1 identifies the device having the invalid CCB

word 3 contains the 5000 series error codes described in chapter 6.

We identify fault diagnostic information in bold print.

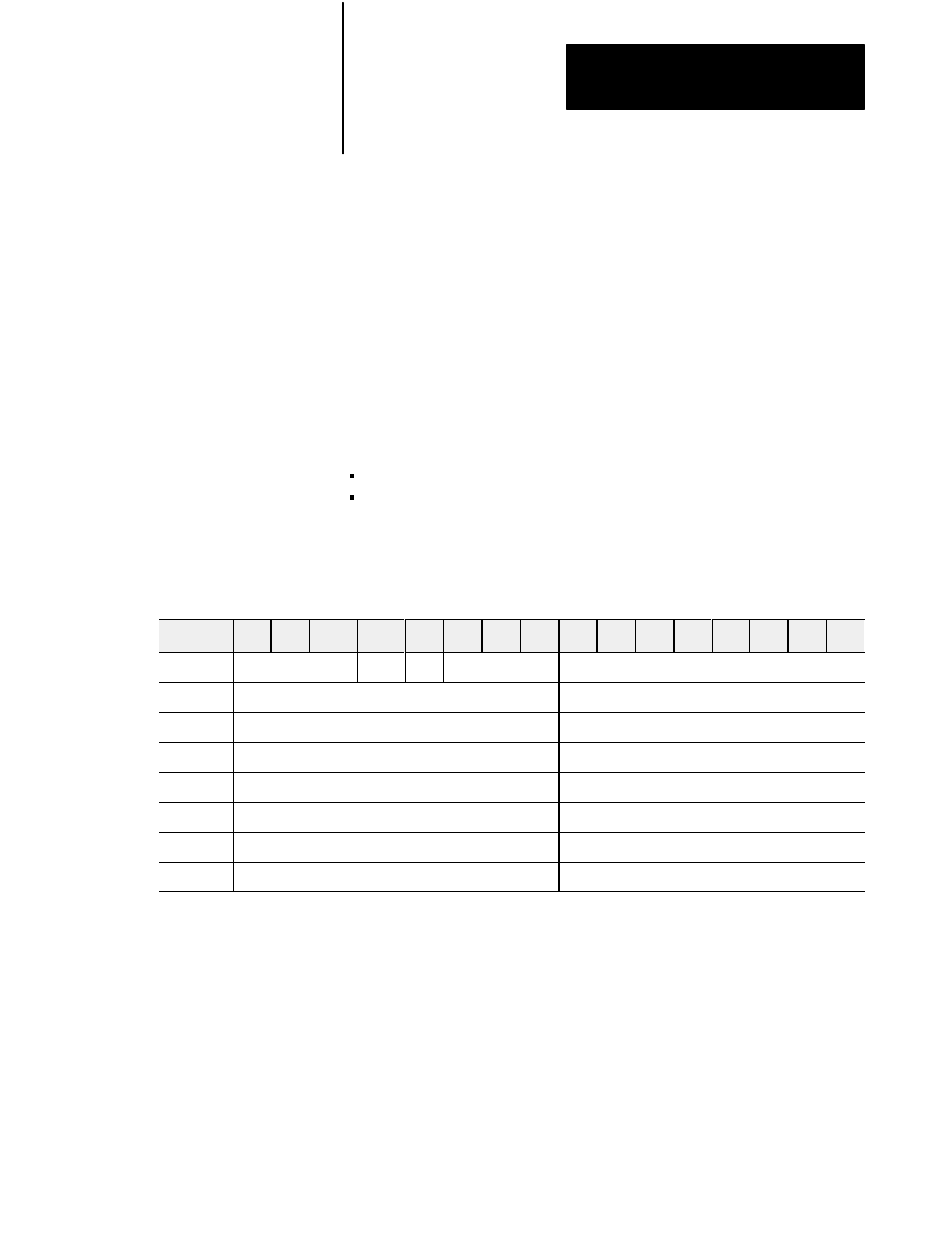

CCS Bit/Word Map

Word

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1

CE

CA

DC

Device ID

2

Number of Numeric Setpoints or 0

Number of BitĆcommand Words or 0

3

Number of BitĆstatus Words, or 5000 series error codes

Number of ASCII Strings, or 5000 series error codes

4

Number of ASCIIĆstatus Strings or 0

Number of NumericĆstatus Words or 0

5

CMD1 (for example, 20) or 0

CMD2 (for example, 49) or 0

:

CMD1 (for example, 20) or 0

CMD2 (for example, 31) or 0

:

CMD1 (for example, 20) or 0

CMD2 (for example, 22) or 0

64

CMD1 (for example, 20) or 0

CMD2 (for example, 44) or 0

Custom Configuration

Status, CCS, to Return

Configuration Status From

the SPI Module