Configuring tuning parameters – Rockwell Automation 1771-TCM TEMPERATURE CONTROL User Manual

Page 52

6–3

Tuning the Loops

Publication 1771Ć6.4.5 - January 1997

Since non-barrel loops are tuned starting from the setpoint,

instead of from a low temperature, the step size should be chosen

to keep the temperature within the operating range.

For example, assume your loop is at the setpoint of 100 degrees,

and the loop output is at 20 percent, when auto-tuning is started.

If the disturbance size is set to 10 percent, the output will be

changed to 30 percent when tuning starts, which will, in turn,

cause the temperature to rise to some value above the setpoint.

You should make the disturbance size as large as possible, while

still insuring that the temperature will not rise out of your

process’s operating range.

•

System Response

The system response setting is used in conjunction with the

system parameters measured during auto-tuning to determine the

proportional, integral, and derivative gains. When you select

slow, the system will react more mildly to changes in setpoint or

temperature, but will not overshoot the setpoint. When you select

fast, the system will react more strongly to changes in setpoint or

temperature, but will likely overshoot the setpoint. This setting

can be changed after a loop is tuned to make small adjustments in

the performance of the loop.

Before you can auto-tune a loop, you must configure the tuning

parameters. To do so:

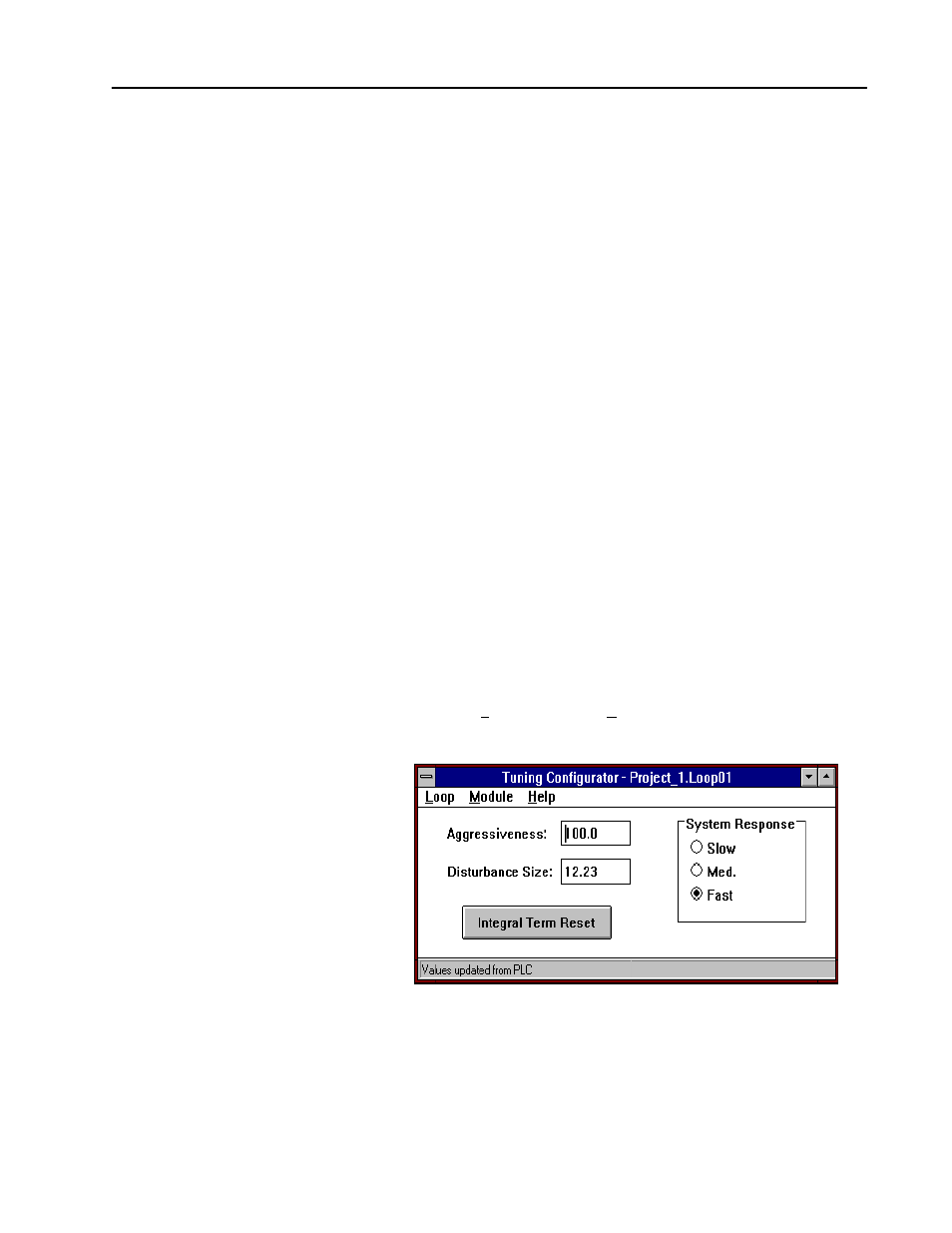

1. At the Module Manager screen, select a loop.

2. From the

Loop menu. select Configure tuning.

The Tuning Configuration screen is opened on the selected loop.

3. Enter your desired settings for aggressiveness and disturbance

size, and select the desired system response.

Note: The Integral Term Reset button is not used during tuning

configuration. Refer to Chapter 7 for information on using the

Integral Term Reset button.

4. Download the tuning parameters.

Configuring Tuning

Parameters