Rockwell Automation 1336T Master/Slave Parallel AC Drv User Manual

Page 26

1336 FORCE-5.19 – August, 2000

3-8

Startup

Parameter 150 (Feedback Device Type) should be set for encoder

feedback (P150 = 1) on both the master and slave drive. See

Encoderless operation set-up in Chapter 5 for parameter settings

specific to encoderless operation.

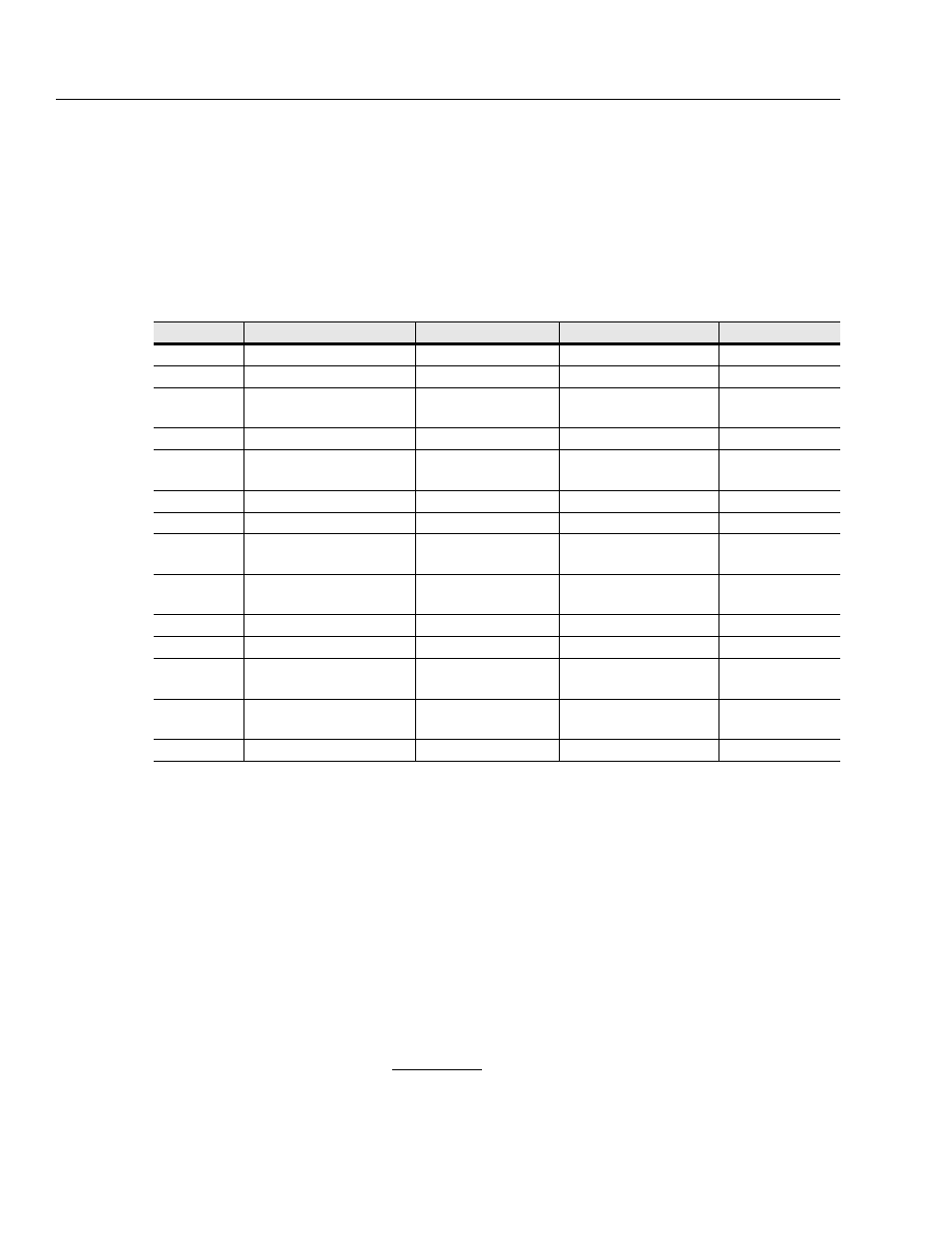

Torque Block Data - Master Drive parameters in the range from 161

to 181 should be set for the process using the settings detailed in the

1336 FORCE user manual. Slave Drive parameters in this range

should be set to zero or their minimum value in most cases.

Configurable parameters should be set as detailed in the following

table:

Inverter Parameters - Parameters 220 through 227 should be set as

follows:

P222 (Inverter Carrier Frequency) can only be set in the master.

This parameter has no meaning for the slave but should be set the

same as the master for consistency.

Note: Carrier frequency (P222) is horsepower dependent and

should be set as follows:

Set to 2000 Hz for Drives 500 HP and below.

Set to 1500 Hz for Drives greater than 500 HP.

Parameters 223 through 226 should be set identically for both the

master and slave. Typically the setting for these parameters are left

at the factory default.

Parameter 227 (CP Options):

Master Drive - For CP 3.04 versions or greater parameter 227

must be set to (0000 0000 0010 0000). For CP3.03 versions or

less, Parameter 227 MUST be set to(0000 0000 0010 1000).

Parameter

Name

Master Setting

Slave Setting

Notes

161

External Iq Reference

Process Setting

Must be 0 or minimum

162

External Torque Ref 1

Process Setting

Must be 0 or minimum

163

Slave Torque Percent 1

Process Setting

Typically = 100%

Must be 0 or minimum

164

External Torque Ref 2

Process Setting

Must be 0 or minimum

165

Slave Torque Percent 2

Process Setting

Typically = 100%

Must be 0 or minimum

166

External Torque Step

Process Setting

Same as Master

174

Minimum Flux Level

25

Same as Master

175

Pos Torque Ref Limit

Process Setting

Typically = 150 or 200

Must be 0 or minimum

176

Neg Torque Ref Limit

Process Setting

Typically = -150 or -200

Must be 0 or minimum

177

Motoring Power Limit

Process Setting

Must be 0 or minimum

178

Regen Power Limit

Process Setting

Must be 0 or minimum

179

Pos Motor Current Ref Limit

Process Setting

Typically = 150 or 200

Must be 0 or minimum

180

Neg Motor Current Ref Limit

Process Setting

Typically = -150 or -200

Must be 0 or minimum

181

Di/Dt Limit

5

5