Before mounting your drive, Interconnect, Cable – Rockwell Automation 1336T Master/Slave Parallel AC Drv User Manual

Page 14: Encoder cable

1336 FORCE-5.19 – August, 2000

2-2

Mounting and Wiring Your 1336 FORCE Master/Slave Drive

Before Mounting Your Drive

Before mounting your drive, consider the following:

•

what tools and equipment you need to mount your drive

•

the distance between the motor and the drive

•

the distance between the drive and other surfaces

Mounting

The Slave drive is intended to be mounted adjacent to the Master

drive. Both the Master and the Slave drive should be located near the

converter (common bus supply).

Mounting clearances for 1336 FORCE Master/Slave Drives are the

same as the requirements for standard G and H frame drives. Refer to

Chapter 2 of the 1336T User Manual (1336 FORCE 5.12) for

guidelines on mounting and heat dissipation requirements.

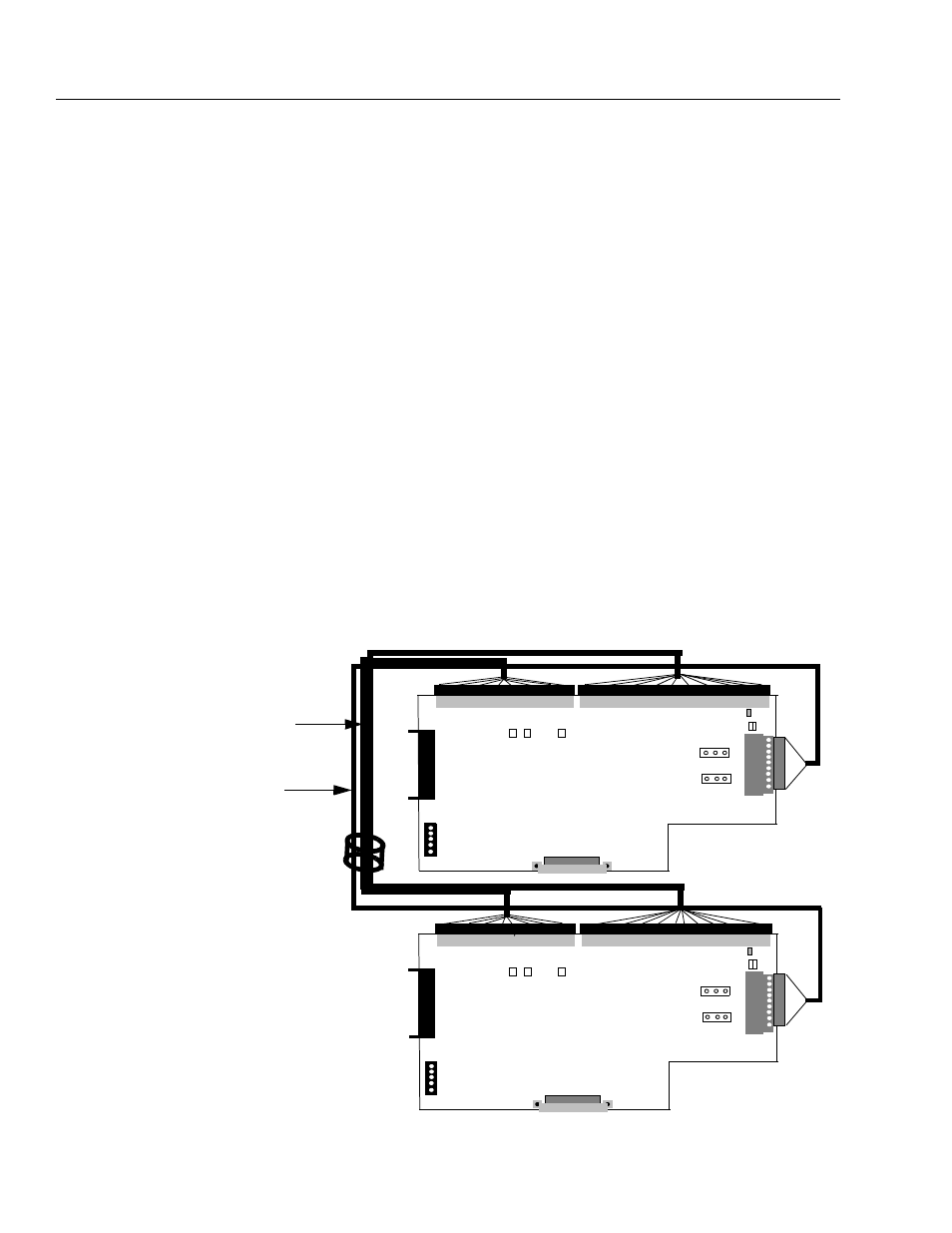

Interconnect Cable Connection

The interconnect cable which runs from the TB12 and TB13

connectors on the Master Main Control Board to the TB12 and TB13

connectors on the Slave Main Control board should be pre-installed

and routed thru a ferrite core on the top of each cabinet. Check that

this cable is connected at both ends and routed correctly thru the

ferrite cores before starting the drive. A disconnected cable will cause

a drive fault at power-up.

If a new interconnect cable is either installed or replaced on-site, the

length of the new or replacement cable must Not exceed 10 ft.

TB12

TB10

J5

J7

TB11

5V

12V

5V

12V

1 2 3

1

2 3

J3

J4

Master

EN VP

CP

TB13

J1

Main Control Board (Master Drive)

TB12

TB10

J5

J7

TB11

5V

12V

5V

12V

1 2 3

1

2 3

J3

J4

Slave

EN VP

CP

TB13

J1

Main Control Board (Slave Drive)

Interconnect

Cable

Ferrite

Core

Encoder

Cable