Rockwell Automation 1502 Medium Voltage Contactor, 800A (Series D and E) User Manual

Page 46

Maintenance

4-17

1502-UM051E-EN-P – June 2013

1. Make sure the contactor is in the open (or tripped) state.

2. Remove latch pivot bolt with a 3/16" Allen key as shown in Figure 4.21, and

remove the lever assembly. The latch spring is no longer retained at this

point and may fall out of the core – do not misplace this spring.

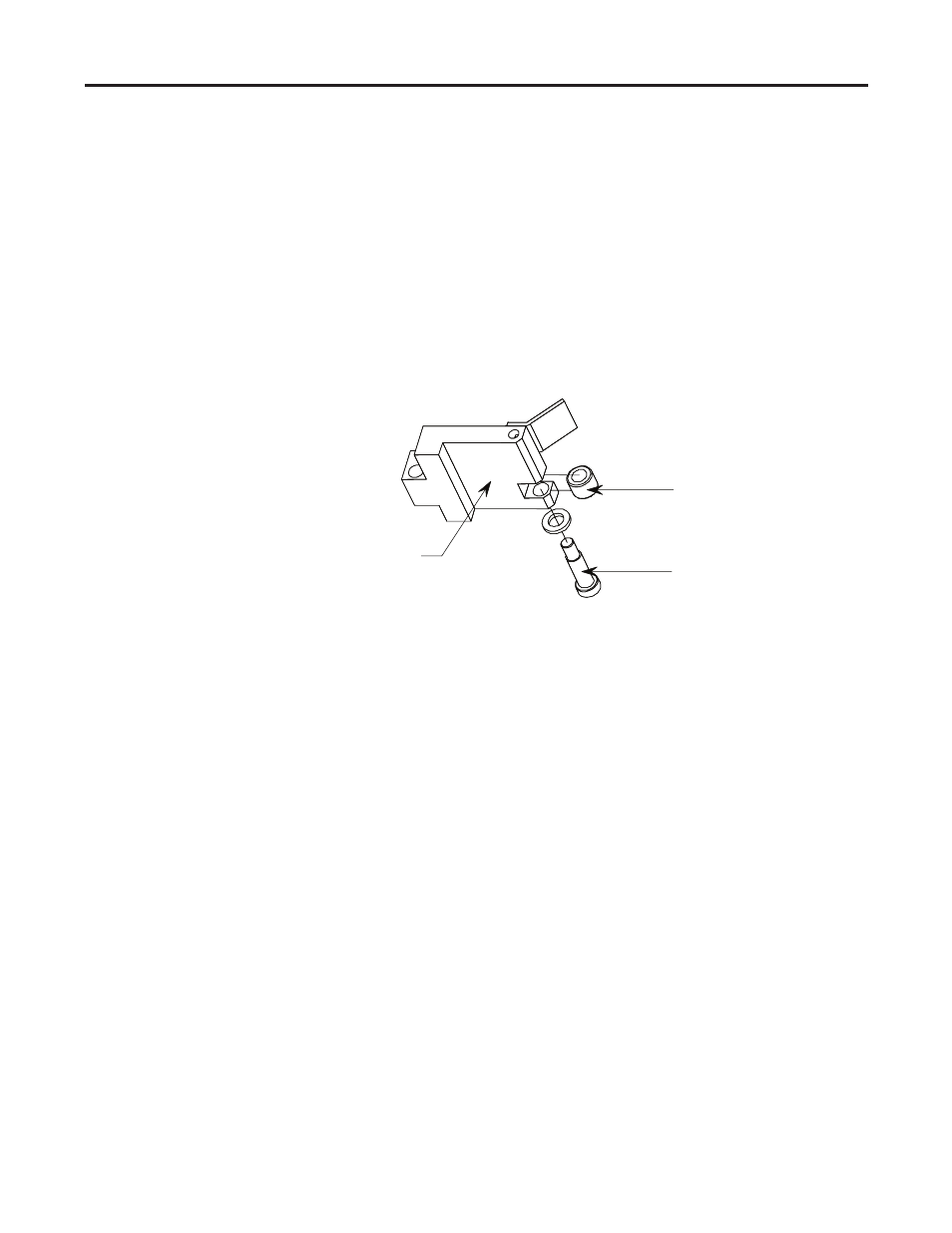

3. Remove the roller mounting bolt as shown in Figure 4.23 allowing the roller

to be removed.

4. Insert the new roller and install the roller mounting bolt.

5. Make sure that the latch spring is seated properly in the core, position the

lever assembly and install the latch pivot bolt. The spring must be seated

properly in the retaining holes in both the core and the lever.

Trip Coil Lever

Roller mounting bolt

Latch roller

Figure 4.23 – Mechanical Latch Assembly

With the exception of the roller, the latch mechanism will last the rated life of

the contactor. If the contactor is used beyond the rated life, the latch mecha-

nism should be refurbished by replacing the lever assembly, latch spring and the

armature plate. These parts can be ordered pre-assembled as Refurbishing Kit

#80158-058-51.

1. Remove latch pivot bolt with a 3/16" Allen key as shown in Figure 4.21, and

remove the lever assembly. The latch spring is no longer retained at this

point and can be removed and discarded.

2. Make sure that the new latch spring is seated properly in the core; position

the new lever assembly and install the latch pivot bolt. The spring must be

seated properly in the retaining holes in both the core and the lever.

3. Loosen the locking nut on the return spring compression bolt and withdraw

the compression bolt until the return spring is relaxed. Remove the return

spring as shown in Figure 4.2.

4. Remove the armature plate mounting bolts. Discard the armature plate and

install the new armature plate. Reinstall the return spring and advance the

compression bolt until the armature plate makes contact with the stop as

shown in Figure 4.10. Advance the bolt one additional full turn to ensure

that the contactor opens fully. Holding the compression bolt in position with a

wrench, tighten the compression bolt locking nut.

Mechanical Latch Roller

Replacement Procedure

Mechanical Latch Mechanism

Refurbishing Procedure