Vacuum bottle integrity test (cont.) – Rockwell Automation 1502 Medium Voltage Contactor, 800A (Series D and E) User Manual

Page 16

2-4

Receiving and Handling

1502-UM051E-EN-P – June 2013

High-voltage is present during this test. Caution should

be exercised during this test since high

voltage testing is

potentially hazardous.

Before doing any work on the contactor, the controller isolat-

ing switch must be in the open position and locked out. If

any control power is used from a separate source, it should

also be isolated. It is also suggested that a “Hot Stick” be

used to ensure equipment is voltage free.

1. The contactor may be tested while it is in the power cell. The line connec-

tion of the contactor must be disconnected and the ground lead from the

Hi-pot tester must be connected to the load side of the contactor.

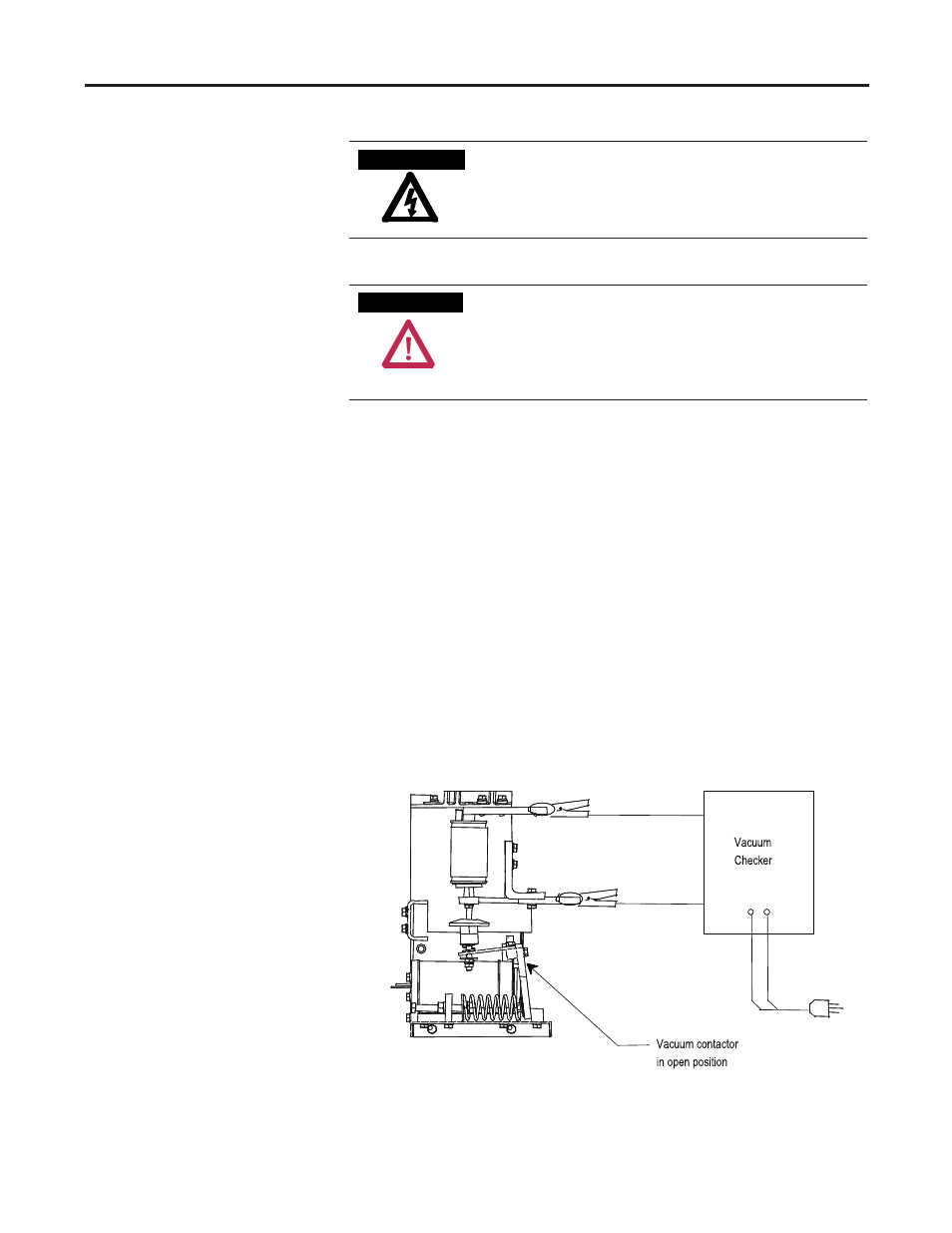

2. With the contactor in the open position, connect the test leads to the

contactor power terminals as shown in Figure 2.2. It is recommended that

an AC hi-pot tester be used. Apply 16 kV for 60 seconds and monitor the

leakage current. It should not exceed 5 mA.

3. If no breakdown occurs, the bottle is in an acceptable condition. If a break-

down occurs, the bottle should be replaced.

Note: Rockwell Automation recommends that, if the contactor has been in

service, all three (3) bottles be replaced at the same time.

4. After the HIGH POTENTIAL VOLTAGE is removed from the bottles,

the metal end caps of the bottles should be discharged with a grounding rod

to remove any residual electrical charge.

Figure 2.2 – Vacuum Bottle Integrity Test Circuit

Vacuum Bottle Integrity Test

(cont.)

A T T E N T I O N

A T T E N T I O N

S H O C K H A Z A R D